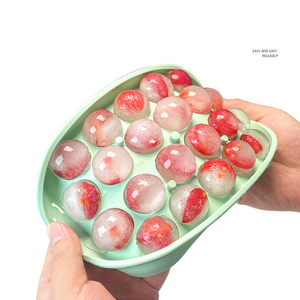

Ice Cube Sphere Maker

Top sponsor listing

Top sponsor listing

1/22

1/22

1/18

1/18

1/33

1/33

1/20

1/20

About ice cube sphere maker

Where to Find Ice Cube Sphere Maker Suppliers?

China remains the central hub for ice cube sphere maker manufacturing, with key production clusters in Guangdong and Shandong provinces. Guangdong—particularly Shenzhen and Dongguan—hosts a dense network of silicone and plastic molding specialists, leveraging advanced injection and compression molding technologies. These regions benefit from mature supply chains for food-grade materials, enabling rapid prototyping and high-volume output. Shandong, meanwhile, focuses on industrial-scale ice-making equipment, including automated sphere-forming machines capable of producing hundreds of kilograms per hour.

The concentration of material suppliers, mold designers, and packaging integrators within 50km radii allows for vertically integrated production. This ecosystem supports lead times as short as 15–25 days for standard orders and enables cost efficiencies, with unit prices for manual silicone molds starting below $0.50 at scale. Buyers gain access to flexible production runs, from small batches for niche markets to container-sized orders, backed by established logistics gateways like Shenzhen and Qingdao ports.

How to Choose Ice Cube Sphere Maker Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Material & Product Compliance

Confirm that products are manufactured from BPA-free, food-grade silicone or PP/PE plastics compliant with FDA, LFGB, and RoHS standards. For export to regulated markets (EU, USA), demand test reports validating material safety and thermal resistance (typically -40°C to 230°C for silicone). Suppliers should provide documentation for color stability, odor neutrality, and dishwasher/microwave/freezer compatibility.

Production & Customization Capability

Assess supplier flexibility through:

- In-house mold design and CNC tooling facilities for custom shapes and sizes

- Capacity for Pantone color matching and logo embossing/debossing

- Packaging customization: private label, blister cards, polybag printing, barcode integration

- Minimum Order Quantity (MOQ) thresholds—ranging from 50 pieces for premium suppliers to 100+ for budget producers

Suppliers with dedicated R&D teams can support 3D ice designs (e.g., rose, diamond, Rubik’s cube) and multi-cavity molds (up to 6 cavities per tray).

Performance & Reliability Metrics

Prioritize suppliers demonstrating:

- On-time delivery rate ≥95%

- Average response time ≤4 hours

- Reorder rate >20%, indicating customer retention

- Online transaction volume exceeding US $200,000 annually as a proxy for market presence

Cross-verify claims with verifiable order history and third-party assurance programs where available.

What Are the Best Ice Cube Sphere Maker Suppliers?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Benhaida Rubber And Plastic Products Co., Ltd. | Shenzhen, CN | Ice Cream Tools, Cake Tools, Baking & Pastry Tools | Color, shape, mold, packaging, label, private label, graphic, size, sleeve, barcode | 97% | ≤4h | 20% | US $230,000+ | 50–100 pcs |

| Guangzhou Raybin Homewares Co., Ltd. | Guangzhou, CN | Reusable Ice Ball Makers, BPA-Free Whiskey Molds | Color, material, size, logo, packaging, graphic | 92% | ≤2h | 28% | US $600,000+ | 100 pcs |

| Shandong Qianrui Machinery Technology Co., Ltd. | Shandong, CN | Industrial Ice Machines, Cold Rooms, Refrigeration Systems | N/A (Equipment-focused) | 100% | ≤1h | <15% | US $9,000+ | 1 set |

| Dongguan Shouhongyu Silicone Products Co., Ltd. | Dongguan, CN | Silicone Ice Molds, 3D Rose & Diamond Shapes | Limited (shape, cavity count) | 44% | ≤8h | 27% | US $30,000+ | 2 pcs |

| Shenzhen Zoho Silicone Products Co., Ltd. | Shenzhen, CN | Clear Ice Ball Molds, Reusable Trays | Color, packaging, labeling | 100% | ≤8h | 25% | US $600+ | 20 packs |

Performance Analysis

Guangzhou Raybin stands out for high reorder rates (28%) and extensive customization, supported by strong online sales performance. Shenzhen Benhaida offers broad design flexibility and competitive MOQs, ideal for branded retail lines. Shandong Qianrui caters exclusively to commercial clients needing full-scale ice production systems, with perfect on-time delivery but limited consumer product focus. Dongguan Shouhongyu provides low MOQs (as low as 2 pieces), beneficial for sampling or micro-brands, though its 44% on-time delivery raises fulfillment concerns. Shenzhen Zoho demonstrates flawless delivery and compliance, suitable for quality-sensitive buyers despite lower revenue volume.

FAQs

How to verify ice cube sphere maker supplier reliability?

Audit suppliers for material certifications (FDA, LFGB), request sample test reports for leakage, durability, and ease of release. Evaluate responsiveness, order history, and customer reviews focusing on packaging integrity and color accuracy. Conduct virtual factory tours to confirm in-house mold-making and quality control processes.

What is the typical sampling timeline?

Standard silicone mold samples take 7–12 days to produce. Custom designs with logos or unique cavities require 14–20 days. Allow additional 5–7 days for international express shipping. Industrial machine prototypes (e.g., 200kg/h sphere makers) may take 30–45 days.

Can suppliers accommodate private label and packaging design?

Yes, most leading suppliers offer full private labeling, including custom box artwork, UPC barcodes, hang tags, and eco-friendly packaging inserts. Minimum branding MOQs typically start at 500 units.

What are common MOQ and pricing ranges?

Manual silicone molds range from $0.25 to $1.96/unit with MOQs of 50–100 pieces. Premium 3D designs or BPA-free certified molds command higher prices. Industrial machines start at $500/set with no incremental MOQ beyond one unit.

How to initiate customization requests?

Submit detailed specifications: desired sphere diameter (typically 50–70mm), cavity count, material type (silicone hardness rating), Pantone colors, logo placement (embossed vs printed), and packaging format. Suppliers with design teams will return digital proofs within 48–72 hours.