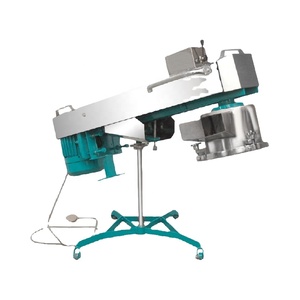

Namkeen Dry Machine Price

About namkeen dry machine price

Where to Find Namkeen Dry Machine Suppliers?

Global supply of namkeen drying machinery is primarily concentrated in China and India, with manufacturers specializing in thermal, air-drying, and vacuum freeze-drying technologies. Chinese suppliers, particularly in Henan and Chongqing, dominate industrial-scale production, offering integrated processing lines capable of handling high-volume snack and nut dehydration. Indian manufacturers, centered in Gujarat and Maharashtra, focus on compact, energy-efficient units tailored for small to mid-sized food processors, with strong emphasis on farsan and namkeen-specific applications.

These regional clusters benefit from localized ecosystems—China’s electromechanical hubs provide access to CNC-machined components and automated control systems, while India’s commercial kitchen equipment sector enables rapid prototyping and cost-effective assembly. Buyers gain advantages in lead time efficiency (typically 20–45 days), with scalability for batch outputs ranging from 50 kg/h to over 1 ton/h. The integration of stainless steel fabrication and PLC-based temperature control systems ensures consistent performance across diverse moisture-sensitive products.

How to Choose Namkeen Dry Machine Suppliers?

Procurement decisions should be guided by the following evaluation criteria:

Technical Specifications & Compliance

Confirm adherence to international safety and quality benchmarks such as CE marking for European markets or ISO 9001-certified production processes. Verify construction materials—industrial-grade stainless steel (SS304/SS316) is essential for corrosion resistance and food safety. Request documentation on heating uniformity tests, airflow dynamics, and energy consumption rates to assess operational efficiency.

Production Capacity & Customization

Evaluate supplier infrastructure based on:

- Minimum factory area exceeding 1,000m² for sustained output

- In-house engineering teams supporting custom configurations (e.g., tilting mechanisms, multi-zone drying)

- Integration of PLC/HMI controls and compliance with IP65 electrical standards

Cross-reference listed product ranges with actual manufacturing capabilities, prioritizing suppliers with dedicated drying equipment lines and proven reorder rates.

Transaction Security & After-Sales Support

Utilize secure payment frameworks that release funds upon inspection clearance. Assess responsiveness through documented metrics—suppliers with response times under 2 hours and on-time delivery rates above 97% demonstrate operational reliability. Request sample units to validate drying performance, especially for hygroscopic snacks like sev, chakli, or bhujia, before scaling procurement.

What Are the Best Namkeen Dry Machine Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Zhengzhou Longer Machinery Co., Ltd. | Henan, CN | Nut & snack processing lines, granule dryers | $2,800–6,000 | 1 set | 100% | ≤2h | Not specified |

| LEENOVA KITCHEN EQUIPMENTS PRIVATE LIMITED | Gujarat, IN | Namkeen making machines, tilting dryers | $310–445 | 1 unit | Not specified | ≤6h | Not specified |

| Chongqing Nakin Electromechanical Co., Ltd. | Chongqing, CN | Air dehydration, freeze-drying systems | $2,000–6,500 | 1 set | 100% | ≤2h | <15% |

| Nanjing Fengleiyi Electromechanical Equipment Co., Ltd. | Jiangsu, CN | Vacuum freeze-drying equipment | $25,100–140,000 | 1 set | 100% | ≤1h | 100% |

| strong machinery LLC | Shandong, CN | Grain, cocoa, and snack dryers | $3,200–9,000 | 1 set | Not specified | ≤4h | Not specified |

Performance Analysis

Nanjing Fengleiyi stands out for high-end vacuum freeze-drying systems, backed by a 100% reorder rate and sub-hour response times, indicating exceptional customer retention. Zhengzhou Longer and Chongqing Nakin demonstrate reliable logistics performance with verified 100% on-time delivery, ideal for time-sensitive procurement. LEENOVA offers the most competitive entry-level pricing, suitable for startups or low-capacity operations. For premium applications requiring minimal oxidation and maximum shelf-life extension, vacuum-based systems from specialized Chinese manufacturers are optimal despite higher capital investment.

FAQs

How to verify namkeen dry machine supplier reliability?

Cross-check certifications (CE, ISO) with official registries. Request factory audit reports or video walkthroughs to confirm production scale. Analyze transaction history for consistency in order fulfillment and post-sale service responsiveness.

What is the typical lead time for drying machines?

Standard units ship within 20–30 days after order confirmation. Customized models with PLC integration or non-standard dimensions require 35–45 days. Air freight reduces delivery to 5–10 days; sea freight averages 25–35 days depending on destination port.

Do suppliers offer customization for namkeen drying?

Yes, most manufacturers support modifications in chamber size, conveyor speed, temperature range (50°C–180°C), and loading capacity. Custom designs for specific snack types (e.g., fried murukku or roasted chana) are available upon technical consultation.

Are samples available before bulk purchase?

Sample availability varies. Some suppliers provide functional demos or rental units; others charge partial fees refundable against future orders. Expect sample lead times of 15–25 days for standard configurations.

What are common packaging and shipping options?

Machines are typically crated in seaworthy wooden enclosures with anti-vibration padding. FOB terms are standard; CIF can be arranged for full logistics coverage. Buyers should confirm voltage compatibility (220V/380V, 50Hz/60Hz) and control panel language settings prior to shipment.