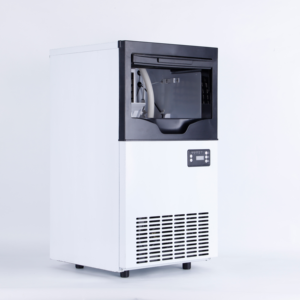

Peak Ice Cube Maker

About peak ice cube maker

Where to Find Peak Ice Cube Maker Suppliers?

China remains the global epicenter for ice cube maker production, with key manufacturing clusters in Guangdong, Henan, and Guangxi provinces driving innovation and scale. Guangdong hosts advanced refrigeration technology firms leveraging proximity to Shenzhen’s electronics supply chain for integrated control systems. Henan specializes in industrial-grade ice machinery, supported by a mature network of metal fabrication and compressor suppliers. Meanwhile, Nanning-based manufacturers in Guangxi focus on cost-efficient, mid-capacity models ideal for commercial food service applications.

These regional ecosystems enable vertical integration—from injection molding and sheet metal processing to final assembly—reducing component lead times by up to 40%. Buyers benefit from concentrated expertise in thermodynamic engineering, refrigerant management (R134a, R404A), and energy-efficient cooling cycles. Average production lead times range from 25–40 days for standard units, with bulk orders (10+ sets) typically fulfilled within 45 days. Localized logistics infrastructure ensures rapid export readiness through major ports like Guangzhou, Qingdao, and Shanghai.

How to Choose Peak Ice Cube Maker Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to international safety and performance standards. Essential certifications include CE (for EU market access), RoHS compliance for restricted substances, and ISO 9001 for quality management systems. Request test reports for key parameters: daily ice yield accuracy, power consumption under load, condenser efficiency, and noise levels (typically ≤65 dB). For commercial deployments, confirm UL or ETL listing eligibility upon request.

Production Capability Assessment

Evaluate supplier infrastructure using these benchmarks:

- Minimum factory area exceeding 3,000m² for stable output

- In-house capabilities covering refrigeration system assembly, electrical panel integration, and stainless steel fabrication

- Dedicated R&D teams supporting custom cycle time adjustments, cooling type (air/water-cooled), and voltage specifications (110V/220V)

- Cross-reference online revenue data and reorder rates (>20% indicates customer retention)

Customization & Quality Control

Leading suppliers offer configurable options including ice size (9g–30g per cube), production capacity (50kg–1,000kg/day), and material grade (food-grade PP, SUS304 stainless steel). Confirm that each unit undergoes 72-hour continuous operation testing before shipment. Prioritize vendors providing real-time response tracking (<2 hours) and documented QC procedures, including leak testing, insulation resistance checks, and compressor burn-in cycles.

Transaction Safeguards

Utilize secure payment terms such as letter of credit or escrow services until post-arrival inspection is completed. Analyze historical on-time delivery performance—target suppliers with ≥98% fulfillment rates. Request sample units to validate build quality, ice clarity, and automation reliability prior to full-scale procurement.

What Are the Best Peak Ice Cube Maker Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| YIWU STAR PEAK COMMODITY CO.,LTD. | Zhejiang, CN | Silicone molds, plastic drinkware, tumblers | 100% | 20% | ≤2h | US $70,000+ | Limited (shape, packaging) |

| Zhengzhou Yize Machinery Co., Ltd. | Henan, CN | Industrial ice machines, block makers | 98% | 31% | ≤2h | US $450,000+ | Color, size, logo, packaging, capacity |

| Guangdong Taihe Refrigeration Technology Co., Ltd. | Guangdong, CN | Cube ice machines, cooler systems | 100% | 33% | ≤2h | US $60,000+ | Capacity, refrigeration type, phase, design, cooling mode |

| Nanning Nanyuanfang Refrigeration Equipment Co., Ltd. | Guangxi, CN | Stainless steel ice makers, block machines | 99% | 15% | ≤5h | US $740,000+ | Size, shape, plug, refrigerant, compressor, panel |

| Shanghai Jingyao Industrial Co., Ltd. | Shanghai, CN | Commercial electric ice makers | 100% | <15% | ≤4h | US $550,000+ | Power, size, capacity |

Performance Analysis

Zhengzhou Yize and Guangdong Taihe stand out for high customization depth and robust technical support, making them ideal for buyers requiring tailored ice output (e.g., crystal-clear cubes for premium bars or large-format blocks for seafood display). Guangdong Taihe achieves perfect on-time delivery and strong repeat business (33% reorder rate), indicating efficient production planning. Nanning Nanyuanfang offers extensive configurability across refrigerant types and electrical specs but has slower average response times. Shanghai Jingyao serves niche commercial clients with scalable capacity options, though its lower reorder rate suggests room for service improvement. Yiwu Star Peak focuses on low-cost silicone molds rather than mechanical units, positioning it for accessory-level sourcing.

FAQs

How to verify peak ice cube maker supplier reliability?

Cross-check ISO/CE certifications with issuing bodies and request product test reports for compressor longevity, ice clarity, and energy draw. Review verifiable transaction histories, focusing on consistent on-time delivery (>98%) and responsive communication. Conduct virtual audits to assess factory conditions and QC workflows.

What is the typical MOQ and pricing range?

For mechanical ice makers, minimum order quantities start at 1 set, with prices ranging from $236 to $9,999 depending on daily output (50kg–1,000kg). Silicone molds have lower thresholds (100–500 pieces) at $0.51–$4.20 per unit. Bulk discounts apply above 10 sets or 1,000 units for accessories.

Can suppliers customize ice cube size and machine dimensions?

Yes, most industrial suppliers allow specification of cube dimensions (standard: 22x22x22mm to 38x38x38mm), bin capacity, and footprint optimization. Custom molds for unique shapes are available through injection molding partners upon request.

Do manufacturers support OEM branding and packaging?

Leading suppliers offer full OEM services including logo printing, branded control panels, custom color finishes, and retail-ready packaging. Setup fees vary based on complexity, with no charge for simple label integration.

What are common lead times and shipping methods?

Standard orders ship in 25–40 days after deposit. Air freight delivers samples in 7–12 days; sea freight takes 25–35 days for FCL/LCL shipments. Most suppliers offer FOB terms, with optional CIF arrangements available upon request.