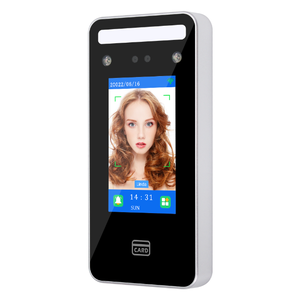

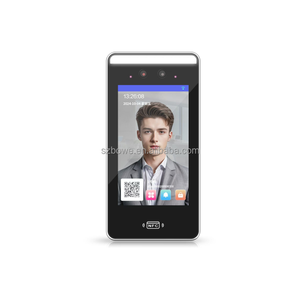

Qr Code In Camera

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/17

1/17

1/3

1/3

1/17

1/17

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

1/31

1/31

0

0

0

0

1/3

1/3

0

0

1/3

1/3

1/16

1/16

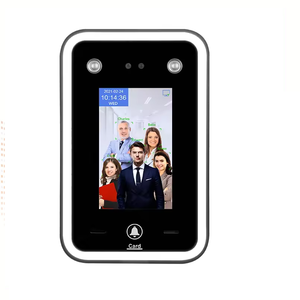

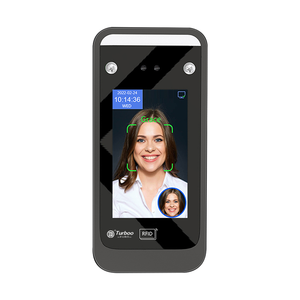

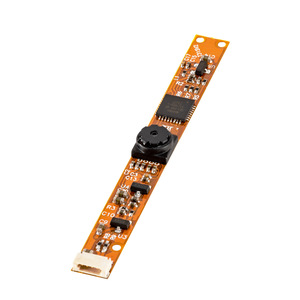

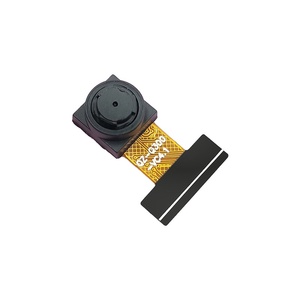

About qr code in camera

Where to Find QR Code in Camera Suppliers?

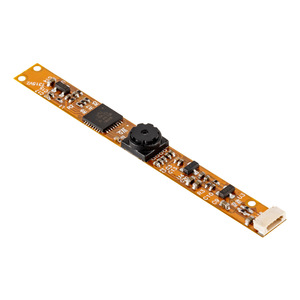

No active suppliers are currently identified in the global market for standalone "QR code in camera" systems as a distinct industrial product category. The integration of QR code recognition functionality into imaging devices is typically achieved through software-enabled solutions rather than dedicated hardware units. As such, manufacturing capabilities are concentrated within electronics and embedded systems hubs—primarily in Guangdong, Jiangsu, and Zhejiang provinces in China—where OEMs and ODMs specialize in smart cameras, IoT modules, and vision sensors.

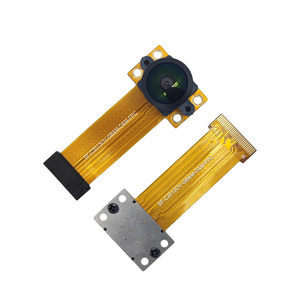

These regions host vertically integrated supply chains for PCB assembly, optical components, and firmware development, enabling rapid deployment of QR-reading camera systems. Production ecosystems support batch manufacturing with scalable outputs, often leveraging existing platforms such as IP cameras, industrial bar code scanners, or mobile vision terminals. Lead times for standard configurations average 20–35 days, with cost efficiencies derived from localized component sourcing and automated SMT lines. Buyers benefit from modular designs that allow integration of QR decoding algorithms via SDKs or API access, reducing time-to-market for customized deployments.

How to Choose QR Code in Camera Suppliers?

Given the absence of direct suppliers in this niche, procurement strategies must focus on evaluating electronic imaging and machine vision manufacturers capable of delivering integrated QR code reading functionality. Prioritize the following verification criteria:

Technical Compliance

Confirm adherence to international standards including ISO 9001 for quality management and IEC 62443 for cybersecurity in networked devices. For European markets, ensure compliance with CE marking directives (EMC, LVD) and RoHS for hazardous substance restrictions. Request documentation validating image sensor performance, decoding accuracy under variable lighting (minimum 85% success rate at 30–100cm distance), and compatibility with common QR formats (including Aztec, Data Matrix, and Micro QR).

Production Capability Audits

Assess infrastructure maturity through objective benchmarks:

- Minimum 3,000m² production area with ESD-protected SMT and testing zones

- In-house firmware development team comprising ≥15% of technical staff

- Automated optical inspection (AOI) and environmental stress screening (thermal cycling, vibration testing)

Validate scalability by reviewing historical order fulfillment data for similar vision-based products, targeting >95% on-time delivery performance.

Transaction Safeguards

Utilize secure payment mechanisms such as letter of credit (L/C) or escrow services tied to milestone inspections. Conduct pre-shipment audits via third-party agencies to verify functional testing logs and packaging integrity. Prototype validation is critical—require working samples demonstrating real-time QR decoding across multiple angles and surface types before volume commitment.

What Are the Best QR Code in Camera Suppliers?

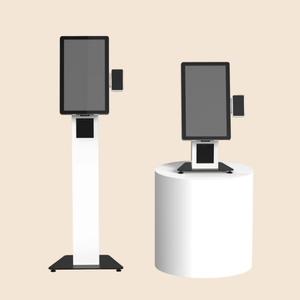

At present, no supplier-specific data is available for entities marketing “QR code in camera” as a discrete product line. However, established manufacturers in the broader industrial imaging sector can be evaluated based on adjacent capabilities. Entities specializing in automated identification, retail scanning systems, or smart surveillance equipment often possess the necessary technical foundation to customize QR-integrated camera modules.

Procurement decisions should emphasize engineering flexibility, software support, and field reliability over branded product listings. Buyers are advised to engage potential partners with proven experience in deploying vision-based decoding systems across logistics, access control, or asset tracking applications.

Performance Analysis

While quantitative supplier rankings cannot be generated without active market participants, strategic sourcing should prioritize companies demonstrating robust R&D pipelines in computer vision and edge processing. Evidence of prior projects involving OCR/OMR integration, low-latency decoding (<100ms response), and support for cloud connectivity (MQTT, HTTP APIs) indicates higher suitability. Geographic proximity to Shenzhen’s electronics ecosystem offers logistical advantages, including faster component replacement cycles and access to contract design houses for co-development.

FAQs

How to verify QR code in camera supplier reliability?

Request documented evidence of completed installations involving QR recognition tasks. Cross-check certifications with accredited bodies and review firmware update histories to assess long-term maintenance capability. Evaluate after-sales support responsiveness and availability of SDKs or configuration tools.

What is the average sampling timeline?

Custom sample development typically requires 25–35 days, inclusive of PCB revision, firmware loading, and functional validation. Off-the-shelf compatible models may ship within 10–15 days if inventory is available. Air freight adds 5–8 days for international delivery.

Can suppliers ship worldwide?

Yes, qualified electronics manufacturers offer global shipping under FOB, CIF, or DDP terms. Ensure compliance with destination regulations regarding wireless transmission (if Wi-Fi/Bluetooth enabled) and electrical safety certifications (e.g., FCC, UKCA). Consolidated sea freight remains optimal for container-scale orders.

Do manufacturers provide free samples?

Sample fees are standard due to configuration complexity. Full reimbursement is common upon placement of minimum order quantities (typically 100+ units). Some suppliers offer loaner units for pilot testing under return agreements.

How to initiate customization requests?

Submit detailed requirements including resolution (720p/1080p), frame rate (≥15fps), decoding engine preferences (ZBar, ZXing), housing material (ABS/aluminum), and operating temperature range. Reputable partners will respond with system architecture diagrams and integration guidelines within five business days.