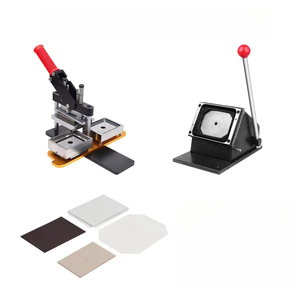

Rectangle Button Maker

1/6

1/6

1/12

1/12

1/29

1/29

1/10

1/10

1/15

1/15

About rectangle button maker

Where to Find Rectangle Button Maker Suppliers?

China remains the central hub for manufacturing rectangle button makers, with key production clusters concentrated in Guangdong and Zhejiang provinces. Dongguan and Foshan in Guangdong host specialized machinery manufacturers that integrate precision tooling with high-efficiency assembly processes, enabling scalable output for both standard and custom configurations. These regions benefit from mature supply chains for steel components, die-casting molds, and manual press mechanisms, reducing material lead times by 20–30% compared to non-specialized zones.

The industrial ecosystem supports rapid prototyping and low-to-mid volume production runs, ideal for promotional product suppliers, craft manufacturers, and private-label brands. Facilities typically operate under lean manufacturing principles, with average factory sizes ranging from 1,000 to 5,000m². This infrastructure enables MOQs as low as 1 set or piece, while maintaining per-unit cost efficiency through modular design and standardized jigs. Lead times for standard models generally range from 7 to 15 days, with expedited processing available for urgent orders.

How to Choose Rectangle Button Maker Suppliers?

Effective supplier selection requires a structured evaluation of technical capability, quality assurance, and transaction reliability:

Production and Engineering Capacity

Assess whether suppliers maintain in-house machining capabilities for mold fabrication and press calibration. Key indicators include CNC processing units, welding stations, and functional testing benches. Prioritize companies listing "Button Making Machines" or "DIY Badge Equipment" as core product lines, signaling domain specialization. Verified customization options—such as adjustable die plates for 53x80mm, 65x90mm, or right-angle corner formats—demonstrate engineering flexibility.

Quality and Compliance Verification

While formal certifications (e.g., ISO 9001, CE) are not universally declared in this segment, operational metrics provide alternative validation. Target suppliers with on-time delivery rates exceeding 97% and reorder rates below 15%, indicating consistent performance and customer satisfaction. Response times under 2 hours correlate with higher service responsiveness during order execution and post-sale support.

Transaction and Sourcing Safeguards

Confirm minimum order terms—most suppliers offer 1-set MOQs, facilitating sample testing prior to volume procurement. Utilize secure payment frameworks where possible, especially when engaging newer suppliers with limited transaction history. Request physical or digital verification of machine operation via video demonstration to validate functionality claims before shipment.

What Are the Best Rectangle Button Maker Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Support | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Foshan Yajiarui Machinery Co., Ltd. | Packaging & Sealing Machines | US $130,000+ | 100% | <15% | ≤1h | Limited | $59–349 | 1 set |

| Dongguan Ruiyee Machinery Co., Ltd. | Custom Badge & Magnet Tools | US $180,000+ | 100% | 15% | ≤2h | Yes | $99–589 | 1 piece |

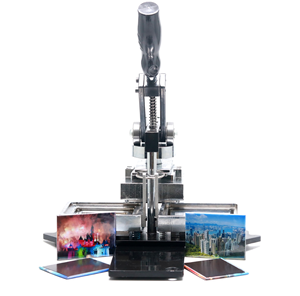

| Dongguan Dinglian Machinery Co., Ltd. | Button & Heat Press Machines | US $230,000+ | 100% | <15% | ≤2h | Yes | $49–655 | 1 set |

| Yiwu Rubysub Digital Graphic Co., Ltd. | Decorative Objects & Magnets | US $150,000+ | 97% | 16% | ≤6h | Limited | $60–710 | 1 piece |

| Yiwu Chuangke Arts & Crafts Co., Ltd. | Button Making & Craft Kits | US $70+ | 33% | <15% | ≤6h | Limited | $150–700 | 1 set |

Performance Analysis

Dongguan-based suppliers dominate in customization and responsiveness, with Ruiyee and Dinglian offering tailored tooling solutions and full material compatibility specifications. Foshan Yajiarui stands out for fast response times (≤1h) and competitive entry pricing from $59. Yiwu Chuangke, despite lower on-time delivery performance (33%), lists premium-priced kits suggesting niche positioning in craft-grade equipment. Buyers seeking reliable mass production should prioritize suppliers with verified revenues above US $150,000 and 100% on-time delivery records. For prototype development, engage suppliers offering single-piece orders to minimize initial investment risk.

FAQs

What materials are compatible with rectangle button makers?

Most machines support metal casings (typically tinplate or aluminum), magnetic backings, plastic covers, and paper inserts. Verify die compatibility with substrate thickness—standard ranges are 0.2–0.5mm for metal components and 0.8–1.2mm for backing cards.

What is the typical lead time for bulk orders?

Standard orders of 50+ sets typically ship within 15–20 days. Customized models with branded dies or unique dimensions may require 25–35 days, including tooling adjustments and pre-shipment testing.

Can suppliers provide OEM/ODM services?

Yes, select manufacturers like Dongguan Ruiyee and Dinglian offer OEM labeling, packaging design, and color customization. Minimum thresholds vary, but branding is often available from 100 units upward.

Do rectangle button makers require power sources?

No, most listed models are manual hand-press systems requiring no electricity. They operate via lever-based compression, making them suitable for small workshops, classrooms, and mobile retail environments.

How to verify machine durability before ordering?

Request stress-test data or video evidence of repeated pressing cycles (minimum 1,000 operations). Examine frame construction—cast steel or reinforced alloy bodies ensure longevity over plastic-composite alternatives. Inquire about spare part availability for pins, springs, and alignment guides.