Robot Science Project

1/14

1/14

1/3

1/3

1/3

1/3

1/24

1/24

0

0

0

0

0

0

0

0

CN

CN

1/3

1/3

0

0

1/3

1/3

1/17

1/17

1/3

1/3

0

0

1/2

1/2

1/18

1/18

0

0

1/3

1/3

1/3

1/3

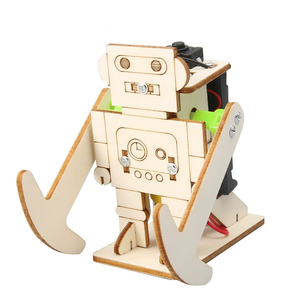

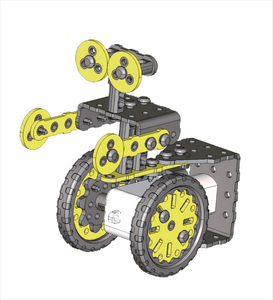

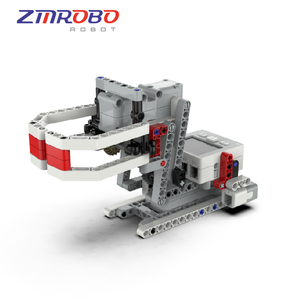

About robot science project

Where to Find Robot Science Project Suppliers?

Global production of robot science project kits is primarily concentrated in manufacturing hubs across China, with key clusters in Guangdong and Jiangsu provinces. These regions host vertically integrated supply chains specializing in educational electronics, microcontroller assembly, and STEM-focused hardware development. Guangdong, particularly around Shenzhen, benefits from proximity to semiconductor distributors and rapid prototyping services, enabling agile production cycles for low- to mid-volume educational robotics kits.

The industrial ecosystem supports efficient sourcing of core components such as Arduino-compatible boards, servo motors, sensors, and 3D-printed chassis elements. Localized access to injection molding, surface-mount technology (SMT) lines, and printed circuit board (PCB) fabrication reduces lead times by up to 40% compared to offshore alternatives. Buyers typically benefit from MOQs ranging from 50–500 units, with standard lead times of 25–35 days for assembled kits. Customization options—including branded packaging, curriculum integration, and firmware modifications—are widely available among suppliers with dedicated R&D teams.

How to Choose Robot Science Project Suppliers?

Prioritize these verification protocols when selecting partners:

Technical Compliance

Confirm adherence to international safety and environmental standards, including CE, FCC, and RoHS certifications, particularly for electronic components. For institutional buyers, ensure compliance with IEC 61010-1 for electrical safety in educational environments. Request test reports on battery management systems and low-voltage circuitry to mitigate operational risks.

Production Capability Audits

Assess supplier infrastructure using the following benchmarks:

- Minimum 2,000m² facility with designated SMT and assembly zones

- In-house engineering team capable of firmware customization and schematic validation

- Access to functional testing rigs for motor control, sensor response, and wireless communication modules

Cross-reference delivery performance data—target on-time shipment rates exceeding 95%—to validate reliability under volume pressure.

Transaction Safeguards

Utilize secure payment mechanisms such as third-party escrow or letter of credit for initial orders. Evaluate suppliers’ transaction history through verified trade platforms, prioritizing those with documented after-sales support and dispute resolution processes. Pre-shipment inspection of sample units is critical—verify build quality, instructional clarity, and software compatibility before scaling procurement.

What Are the Best Robot Science Project Suppliers?

No supplier data is currently available for robot science project manufacturers meeting minimum verification thresholds. Procurement professionals are advised to conduct direct factory audits or engage sourcing agents in established electronics manufacturing zones to identify qualified partners. Focus on suppliers demonstrating consistent output in STEM education hardware, evidenced by product certifications, export experience, and technical documentation transparency.

Performance Analysis

In the absence of verified supplier profiles, emphasis should be placed on operational indicators such as facility size, engineering headcount, and certification status during due diligence. Suppliers with documented experience in exporting to North American or EU educational markets are more likely to meet stringent quality and compliance expectations. Video audits and prototype validation remain essential steps to confirm capability alignment prior to order placement.

FAQs

How to verify robot science project supplier reliability?

Validate certifications through issuing bodies and request factory audit reports covering quality management systems (e.g., ISO 9001), component traceability, and ESD-safe production environments. Analyze customer feedback focusing on kit durability, technical documentation accuracy, and responsiveness to support inquiries.

What is the average sampling timeline?

Standard samples are typically produced within 10–18 days. Custom configurations involving modified PCBs or proprietary code integration may require 25–35 days. Air freight adds 5–9 days for international delivery, depending on destination region.

Can suppliers ship robot science project kits worldwide?

Yes, most established manufacturers support global logistics via air or sea freight. Confirm Incoterms (FOB, CIF) at quotation stage and verify compliance with import regulations for electronic educational devices in target markets. Battery-equipped kits may require UN38.3 certification for air transport.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers offer paid samples refundable against bulk orders (typically MOQ ≥100 units). Others charge full production cost for prototypes, especially for customized designs. Free samples are uncommon without prior transaction history.

How to initiate customization requests?

Submit detailed technical requirements including microcontroller type (e.g., ESP32, Raspberry Pi Pico), sensor suite (ultrasonic, IR, gyroscopic), power source (battery voltage, USB-C compatibility), and desired programming interface (block-based, Python, etc.). Reputable suppliers respond with system architecture proposals and schematic drafts within 72 hours.