Shutter Spring Machine Price

CN

CN

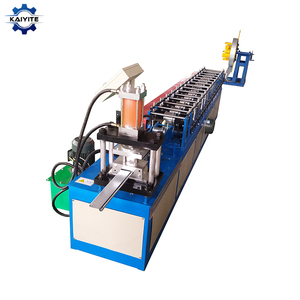

About shutter spring machine price

Where to Find Shutter Spring Machine Suppliers?

China remains the central hub for shutter spring machine manufacturing, with key industrial clusters in Tianjin, Shaanxi, Beijing, Foshan, and Zhengzhou offering specialized production ecosystems. These regions host vertically integrated facilities capable of producing both individual springs and full-scale automated coiling machinery. The concentration of metal processing expertise, CNC engineering talent, and logistics infrastructure enables cost-efficient production and rapid export fulfillment.

Suppliers in these zones benefit from proximity to raw material sources—particularly high-carbon spring steel—and established networks of component manufacturers. This localization reduces lead times by 20–30% compared to offshore alternatives. Buyers can access a spectrum of offerings: from compact semi-automatic units priced under $1,000 to fully automated CNC-controlled systems exceeding $30,000. Lead times typically range from 15 to 45 days depending on customization level and order volume, with air freight options available for urgent component procurement.

How to Choose Shutter Spring Machine Suppliers?

Effective supplier selection requires rigorous evaluation across three core dimensions:

Technical Capability Verification

Confirm that suppliers possess in-house engineering and machining capabilities for precision spring coiling. Look for evidence of CNC-controlled wire forming systems, torsion calibration tools, and quality testing protocols. For machine producers, verify technical specifications such as axis count (e.g., 5-axis or 10-axis CNC), compatible wire diameter ranges (commonly 3–8mm), and integration with automated feeding systems.

Production & Quality Assurance Infrastructure

Assess operational scale through objective indicators:

- Facility size and monthly output capacity (where disclosed)

- In-house R&D teams focused on mechanical automation

- Compliance with international standards such as ISO 9001, CE, or RoHS (if exporting to regulated markets)

- On-time delivery performance (target ≥98%) and response efficiency (≤5 hours preferred)

Cross-reference product listings with actual machine specifications and request test reports for load endurance and cycle life where applicable.

Transaction Security & Customization Support

Prioritize suppliers offering third-party transaction protection and documented after-sales service. Evaluate customization depth—some manufacturers support material selection, color coding, packaging labeling, and OEM branding. Confirm whether sample units are available for functional testing prior to bulk orders. MOQs vary significantly: while some accept single-unit trials, others require minimum batches of 50–200 pieces for components or full machine sets.

What Are the Best Shutter Spring Machine Suppliers?

| Company Name | Main Products | Product Range (Listings) | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Tianjin Lantoo International Trade Co., Ltd. | Springs, Door & Window Accessories | 686+ | $3.08–5.88 | 1–100 pcs | 100% | ≤2h | 21% | $30,000+ |

| Shaanxi Haven Equipment Co., Ltd. | Spring Coiling Machines, CNC Lathes | 121+ | $1,800–3,000 | 1 unit | 100% | ≤5h | <15% | $50,000+ |

| Beijing Ron-En Machinery And Integration Co., Ltd. | Spring Coiling Machines, Wire Drawing Systems | 3,351+ | $9,800–30,000 | 1 set | 100% | ≤10h | <15% | $3,000+ |

| Foshan Gishines Metals Industrial Limited | Door & Window Accessories, Shutters | 447+ | $1.58–3.20 | 200 pcs | 100% | ≤2h | 100% | $200,000+ |

| Zhengzhou Yize Machinery Co., Ltd. | Automatic Spring Coiling Machines, Mattress Equipment | Multiple listings | $800–10,800 | 1 set | 98% | ≤2h | 31% | $450,000+ |

Performance Analysis

Suppliers like Foshan Gishines and Zhengzhou Yize demonstrate strong market responsiveness and high reorder rates, indicating customer satisfaction with pricing and delivery consistency. Foshan Gishines stands out for low-cost spring components with a 100% reorder rate, ideal for buyers prioritizing consumable replacement parts. In contrast, Shaanxi Haven and Zhengzhou Yize offer mid-range CNC coiling machines suitable for small to medium production lines, balancing affordability and automation. Beijing Ron-En provides high-end, large-scale systems but exhibits lower online transaction volume despite extensive product coverage. Tianjin Lantoo caters to component-level sourcing with flexible MOQs and competitive per-unit pricing. Buyers seeking turnkey automation should prioritize suppliers listing complete spring manufacturing lines and supporting technical documentation.

FAQs

What is the typical price range for shutter spring machines?

Manual or semi-automatic models start at $800–$1,800 per unit. Fully automated CNC coiling machines range from $2,800 to over $10,000, with premium multi-axis systems reaching $30,000. Individual shutter springs are priced between $1.58 and $5.88 per piece depending on material grade and order volume.

Do suppliers offer customization options?

Yes, select manufacturers support material type, wire diameter, spring length, surface treatment (e.g., galvanization), and OEM branding. Full machine builders may also integrate custom control panels or feeding mechanisms upon request. Confirm design flexibility before placing orders.

What are common MOQ requirements?

Component suppliers often require 50–200 pieces minimum, though some allow single-piece sampling. Complete machine vendors typically set MOQ at 1 unit or set. Negotiation is possible for mixed-product container shipments.

How to verify machine quality before purchase?

Request product videos, factory certifications, and test reports on spring tensile strength and machine cycle durability. Where feasible, order samples or conduct virtual audits via live video tour of the production line. Third-party inspection services can validate pre-shipment quality.

Can suppliers handle international shipping?

Most experienced exporters manage global logistics under FOB, CIF, or DAP terms. Confirm packaging standards (wooden crates recommended for machinery) and customs documentation support. Sea freight is standard for heavy equipment; air shipping applies to spare parts or prototypes.