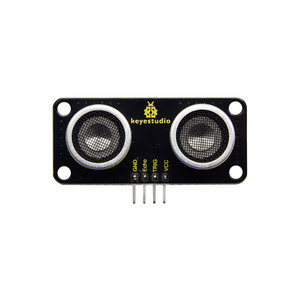

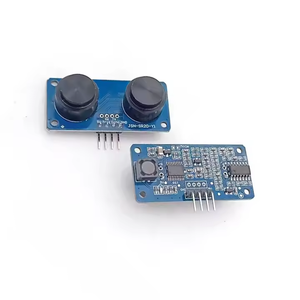

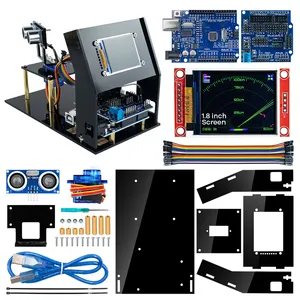

Ultrasonic Sensor Arduino Wholesaler

Top sponsor listing

Top sponsor listing

1/20

1/20

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/28

1/28

1/3

1/3

1/11

1/11

1/2

1/2

1/3

1/3

1/3

1/3

0

0

1/1

1/1

1/3

1/3

0

0

About ultrasonic sensor arduino wholesaler

Where to Find Ultrasonic Sensor Arduino Wholesalers?

China remains the central hub for electronic component manufacturing, with high-density supplier clusters in Guangdong and Zhejiang provinces leading production of embedded sensing solutions. Shenzhen, located in Guangdong, hosts over 70% of China’s electronics OEMs and ODMs, supported by a fully integrated supply chain spanning PCB fabrication, microcontroller programming, and surface-mount technology (SMT) assembly. This ecosystem enables rapid prototyping and scalable fulfillment for ultrasonic sensor modules compatible with Arduino platforms.

These industrial zones benefit from concentrated technical labor pools and streamlined logistics, allowing wholesalers to maintain low overhead and fast turnaround. Suppliers in Shenzhen’s Huaqiangbei district and Hangzhou’s Binjiang zone operate within proximity to testing laboratories, component distributors, and export terminals—reducing lead times by up to 40% compared to non-specialized regions. Buyers gain access to modular designs, pre-flashed firmware options, and batch calibration services, with standard order cycles averaging 15–25 days for quantities between 1,000 and 10,000 units.

How to Choose Ultrasonic Sensor Arduino Wholesalers?

Implement structured evaluation criteria to ensure technical reliability and supply chain continuity:

Quality & Compliance Verification

Confirm adherence to RoHS and CE standards for electromagnetic compatibility and hazardous substance restrictions. For integration into commercial IoT or industrial automation systems, request test reports validating performance under variable temperature (−10°C to +70°C) and humidity (10–90% RH). Suppliers should provide oscilloscope waveforms and distance accuracy logs across 2cm–400cm ranges.

Production Capacity Assessment

Evaluate operational scale through key indicators:

- Minimum monthly output capacity exceeding 50,000 units

- In-house SMT lines with automated optical inspection (AOI)

- Dedicated R&D personnel focused on signal noise reduction and EMI shielding

Cross-reference factory certifications with actual yield rates, targeting defect rates below 0.3% in recent production batches.

Procurement Safeguards

Utilize milestone-based payment terms tied to production milestones and third-party pre-shipment inspections. Request sample batches before bulk ordering to validate consistency in pin alignment, housing durability, and trigger/response timing. Prioritize suppliers offering I²C or UART interface customization and supporting documentation including datasheets, Arduino libraries, and calibration protocols.

What Are the Best Ultrasonic Sensor Arduino Wholesalers?

No supplier data is currently available for detailed comparison. Buyers are advised to initiate sourcing inquiries through verified trade channels and conduct preliminary audits focusing on technical responsiveness, compliance documentation, and manufacturing transparency. Given the commoditized nature of HC-SR04-type modules, differentiation typically arises in post-sales support, firmware flexibility, and batch traceability rather than core functionality.

Performance Analysis

In absence of specific supplier profiles, procurement focus should shift toward process rigor. Leading wholesalers distinguish themselves through standardized aging tests (48-hour powered operation), consistent use of calibrated reference targets (±1mm tolerance), and version-controlled firmware deployment. Emphasis should be placed on suppliers who document ESD protection measures during packaging and offer configurable pulse echo thresholds. As product homogenization is high, reorder behavior often correlates with service efficiency—particularly response time to technical queries and resolution of shipment discrepancies.

FAQs

How to verify ultrasonic sensor wholesaler reliability?

Request copies of quality management system certifications (e.g., ISO 9001) and validate testing procedures for sensor drift, cross-talk resistance, and power surge tolerance. Conduct video audits of production lines to confirm SMT placement accuracy and functional testing stations. Analyze customer feedback related to long-term stability and failure-in-field rates.

What is the average sampling timeline?

Standard samples are typically dispatched within 5–7 business days after inquiry. Custom configurations involving altered beam angles, waterproof encapsulation, or specialized connectors may require 12–18 days. Air shipping adds 4–7 days depending on destination region.

Can suppliers ship globally?

Yes, most established electronics wholesalers support international delivery via DHL, FedEx, or sea freight for container loads. Confirm Incoterms (FOB Shenzhen, CIF Rotterdam, etc.) and ensure compliance with import regulations regarding electronic components in target markets. Pre-shipment documentation should include packing lists, commercial invoices, and material declarations.

Do wholesalers provide free samples?

Sample policies vary by order potential. Many suppliers offer one complimentary unit for qualified buyers committing to MOQs above 500 pieces. For evaluation without immediate volume commitment, expect to cover sample costs and shipping, typically ranging from $5–$15 per unit.

How to initiate customization requests?

Submit detailed specifications including operating voltage range (typically 3.3V–5.5V), desired detection range, housing dimensions, connector type, and environmental rating (e.g., IP65). Reputable partners will respond with revised schematics, updated BOMs, and prototype delivery timelines within 5–10 days.