Ultrasonic Sensors Arduino

Top sponsor listing

Top sponsor listing

1/2

1/2

1/3

1/3

1/3

1/3

1/20

1/20

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

0

0

1/3

1/3

1/1

1/1

1/1

1/1

1/28

1/28

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

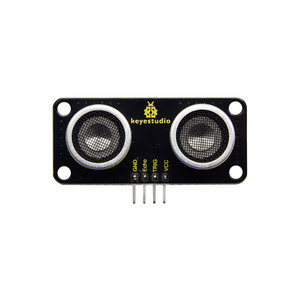

About ultrasonic sensors arduino

Where to Source Ultrasonic Sensors for Arduino Applications?

China remains the central hub for manufacturing ultrasonic sensors compatible with Arduino platforms, with key production clusters in Shenzhen and Yueqing. These regions host vertically integrated supply chains that combine electronic component fabrication, sensor assembly, and rapid prototyping capabilities. Shenzhen’s electronics ecosystem enables agile development cycles, supporting quick iteration for STEM education kits and IoT integration projects. Meanwhile, Yueqing specializes in industrial-grade proximity and level sensing solutions, leveraging established electrical component manufacturing infrastructure.

The concentration of technical suppliers within 50km radii in these zones ensures efficient access to PCB fabricators, plastic molding services, and calibration equipment. This proximity reduces lead times by up to 40% compared to decentralized sourcing models. Buyers benefit from scalable production capacity, with monthly output ranging from thousands to tens of thousands of units depending on model complexity. Localization also lowers logistics costs and supports just-in-time inventory strategies for global distributors and OEMs.

How to Evaluate Suppliers of Ultrasonic Sensors for Arduino?

Procurement decisions should be guided by systematic supplier assessment across three core dimensions:

Technical Capabilities and Product Range

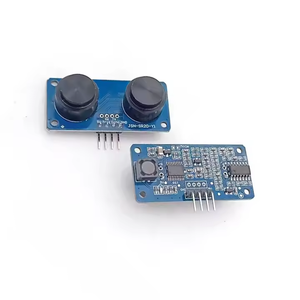

Confirm suppliers offer compatibility with standard Arduino development environments (e.g., IDE support, library availability). Assess whether product lines include variants such as waterproof models (IP67 rated), low-power consumption units, or extended detection range options (up to 7m). Key performance indicators include beam width, blind zone size (as low as 3cm), and output signal types (analog, digital, RS485).

Quality Assurance and Compliance

Prioritize suppliers adhering to international quality standards. While explicit ISO certification is not always declared, high-performing manufacturers demonstrate compliance through consistent on-time delivery rates exceeding 95%. Look for evidence of internal testing protocols, including echo stability verification and temperature drift compensation. For export-bound orders, ensure components meet RoHS directives and electromagnetic compatibility requirements.

Operational Reliability Metrics

Analyze verifiable performance data:

- On-time delivery rate ≥95% indicates reliable production planning

- Average response time ≤4 hours reflects strong customer service infrastructure

- Reorder rate below 15% may suggest niche specialization; rates above 25% indicate broader market acceptance

- Minimum order quantities (MOQ) typically range from 1–20 units, enabling low-volume testing

Cross-reference transaction history with customization capability—such as labeling, packaging, cable length, or material plating—to assess flexibility for private-label or integrated system deployments.

Top Suppliers of Ultrasonic Sensors for Arduino: Performance Overview

| Company Name | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Verified Supplier Type |

|---|---|---|---|---|---|---|---|

| Shenzhen Dianyingpu Technology Co., Ltd. | Ultrasonic Sensors, Liquid Level Sensors, Proximity Sensors | US $120,000+ | 100% | ≤2h | <15% | Limited | |

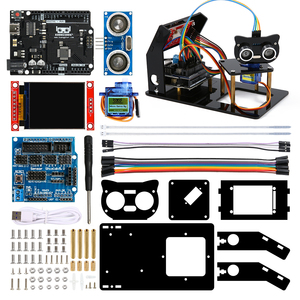

| Acebott Stem Education Tech Co., Ltd. | Ultrasonic Sensor Modules, Robotics Kits, Smart Car Kits | US $70,000+ | 100% | ≤3h | 23% | Yes | Multispecialty Supplier |

| Shenzhen Robotlinking Technology Co., Ltd. | Robotics Kits, Development Boards, Educational Electronics | US $70,000+ | 95% | ≤3h | 31% | Limited | |

| Yueqing Bxuan Electrical Co., Ltd. | Proximity Sensors, Ultrasonic Sensors, Magnetic Sensors | US $90,000+ | 98% | ≤4h | <15% | Yes | Custom Manufacturer |

| Shenzhen Hong Shu Yuan Technology Co., Ltd. | Sensor Modules, Starter Kits, Power Supplies | US $140,000+ | 92% | ≤9h | 29% | Yes | Multispecialty Supplier |

Performance Analysis

Shenzhen Dianyingpu leads in operational reliability with a perfect 100% on-time delivery record and sub-2-hour response times, making it ideal for time-sensitive procurement. Acebott and Shenzhen Hong Shu Yuan offer extensive customization—ideal for branded educational kits—though slightly longer response windows may affect urgent requests. Yueqing Bxuan distinguishes itself as a dedicated custom manufacturer with industrial sensor expertise, suitable for applications requiring nickel-plated brass housings or relay outputs. Higher reorder rates (e.g., 31% at Robotlinking) suggest strong end-user satisfaction in STEM and robotics markets.

FAQs

What are typical MOQs and pricing for Arduino-compatible ultrasonic sensors?

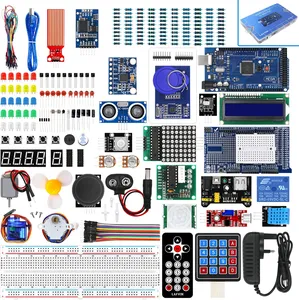

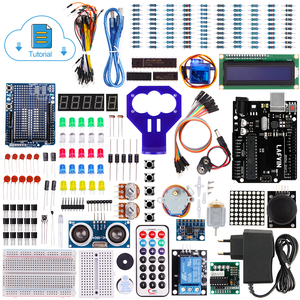

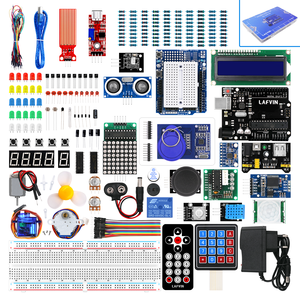

Minimum order quantities range from 1 unit (for evaluation samples) to 20 pieces for bulk discounts. Unit prices vary by model: basic HC-SR04 equivalents start at $1.65/unit (MOQ 20), while advanced modules with LoRaWAN or IP67 ratings reach $23+ per unit. Starter kits including multiple sensors and controllers are priced between $12–$42 depending on completeness.

How long do production and shipping take?

Standard lead time for ready-to-ship orders is 3–7 days. Custom configurations (e.g., logo printing, special cabling) require 10–15 days. International air freight adds 5–10 business days. Sea freight is viable for container-sized orders (>500 units), reducing per-unit logistics costs by 60–70%.

Can suppliers provide technical documentation and code libraries?

Reputable suppliers supply datasheets, pinout diagrams, and Arduino-compatible sample code (often via GitHub links or email attachment). Verify pre-purchase that libraries exist for specific models (e.g., NewPing or URMeter for HC-SR04 derivatives) to ensure seamless integration.

Are waterproof and outdoor-rated models available?

Yes, several suppliers offer IP67-certified ultrasonic sensors designed for outdoor or wet environments. These feature sealed casings and corrosion-resistant materials, with detection ranges maintained under rain or dust exposure. Confirm beam angle and temperature operating range (-10°C to +70°C typical) for environmental suitability.

What customization options are commonly supported?

Available modifications include cable length (10cm–5m), connector type (JST, XH, screw terminals), housing color, laser-engraved branding, and packaging format (blister packs, retail boxes). Some suppliers also support firmware adjustments or analog/digital output configuration upon request.