Sensor Sensor Arduino

Top sponsor listing

Top sponsor listing

1/2

1/2

1/2

1/2

1/2

1/2

1/1

1/1

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

0

0

0

0

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/1

1/1

1/3

1/3

1/3

1/3

0

0

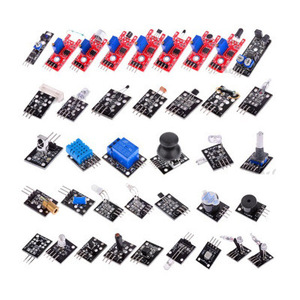

About sensor sensor arduino

Where to Find Sensor Arduino Suppliers?

China leads global production of Arduino-compatible sensors, with manufacturing hubs concentrated in Guangdong and Zhejiang provinces. Shenzhen, within Guangdong, hosts over 70% of China’s electronics component suppliers, leveraging its status as a global hardware innovation center. The city’s ecosystem integrates rapid prototyping services, PCB fabrication, and surface-mount technology (SMT) lines, enabling agile development cycles. Zhejiang’s Ningbo and Hangzhou regions specialize in industrial-grade sensor modules, supported by automated assembly facilities that reduce unit costs by 18–25% compared to non-Asian manufacturers.

These clusters offer vertical integration across semiconductor packaging, firmware programming, and final testing, allowing for batch scalability and customization. Suppliers operate within tightly connected supply networks—raw materials, microcontrollers, and passive components are sourced within 30km, reducing inventory lead times. Buyers benefit from average production lead times of 15–25 days for standard orders, 20–35% cost savings due to localized logistics, and flexibility in MOQs ranging from 10 to 5,000 units. Many factories support dual sourcing of critical ICs to mitigate component shortages.

How to Choose Sensor Arduino Suppliers?

Adopt the following verification framework when evaluating potential partners:

Quality and Compliance Standards

Confirm adherence to ISO 9001 for quality management systems. For export to EU and North American markets, RoHS and CE compliance is essential to meet environmental and electromagnetic compatibility regulations. Request test reports for key performance metrics such as signal accuracy, response time, and thermal stability across operating ranges (-40°C to +85°C).

Production and Technical Capacity

Assess core operational capabilities:

- Minimum 2,000m² factory area with ESD-protected SMT and testing zones

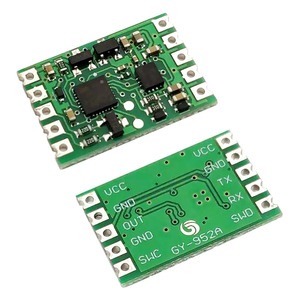

- In-house firmware development team (minimum 5 engineers) for custom calibration or protocol adaptation (e.g., I2C, UART, Modbus)

- Automated optical inspection (AOI) and functional testing stations for defect detection

Correlate facility scale with order consistency—factories with >95% on-time delivery rates typically maintain buffer stock of common MCUs like ATmega328P and ESP32.

Procurement and Transaction Security

Utilize secure payment methods such as third-party escrow until product validation is complete. Review historical transaction data where available, focusing on dispute resolution speed and sample accuracy. Pre-shipment inspection through third-party auditors (e.g., SGS, TÜV) is recommended for orders exceeding 1,000 units. Always request working prototypes before mass production to verify integration compatibility with target Arduino platforms.

What Are the Best Sensor Arduino Suppliers?

No supplier data is currently available for analysis. Buyers should prioritize companies with verifiable manufacturing infrastructure, documented compliance certifications, and transparent communication channels. Due to high market fragmentation, direct engagement via trade shows (e.g., Canton Fair, Electronica China) or B2B portals with verified transaction histories is advised to identify qualified partners.

Performance Analysis

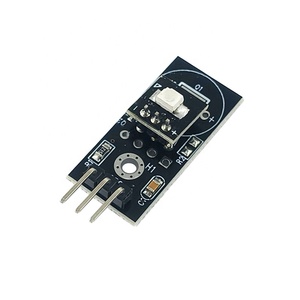

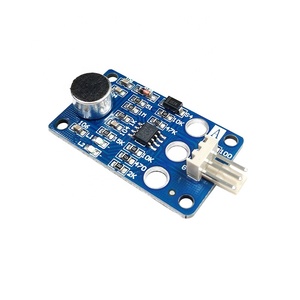

In the absence of specific supplier data, procurement focus should remain on operational transparency and technical agility. Leading-tier manufacturers typically demonstrate responsiveness (average reply time <4 hours), support for small-batch customization, and clear documentation of sensor specifications including sensitivity, power draw, and interface protocols. Prioritize suppliers offering sample units with detailed datasheets and code libraries for Arduino IDE compatibility. As automation demand grows, suppliers with IoT integration experience—supporting Wi-Fi, LoRa, or BLE output—are increasingly strategic for smart sensing applications.

FAQs

How to verify sensor Arduino supplier reliability?

Cross-validate ISO and RoHS certifications with official databases. Request audit trails covering component traceability, soldering profiles, and burn-in testing procedures. Evaluate real-world performance through customer case studies, particularly in industrial automation or environmental monitoring deployments.

What is the average sampling timeline?

Standard sensor samples take 7–14 days to produce. Custom variants requiring firmware modification or mechanical rehousing extend to 20–30 days. International air shipping adds 5–9 days depending on destination. Sample costs typically range from $15–$50 per unit, refundable against bulk orders above 500 pieces.

Can suppliers ship Arduino sensors worldwide?

Yes, most established manufacturers offer global shipping under FOB, CIF, or DDP terms. Confirm export licensing for restricted electronic components and ensure packaging meets IEC 60721-3-4 standards for humidity and shock protection during transit. Air freight is optimal for samples; sea freight is cost-efficient for containerized orders above 5,000 units.

Do manufacturers provide free samples?

Free samples are uncommon but negotiable for high-volume commitments. Suppliers may waive fees for orders projected to exceed 1,000 units annually. Development kits—including multiple sensor types—are often offered at discounted bundles to facilitate system integration testing.

How to initiate customization requests?

Submit detailed technical requirements: sensing parameter (temperature, motion, gas, etc.), output signal type (analog, digital, PWM), housing dimensions, cable length, and environmental rating (IP65, etc.). Reputable suppliers will respond with schematic diagrams, pinout configurations, and firmware API options within 72 hours. Prototype delivery follows in 3–5 weeks, including pre-compliance EMC testing if required.