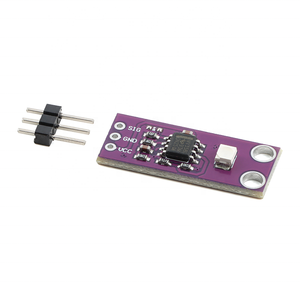

Infrared Sensor Arduino

1/3

1/3

1/3

1/3

1/8

1/8

1/3

1/3

1/2

1/2

0

0

1/5

1/5

1/15

1/15

0

0

0

0

1/1

1/1

1/3

1/3

1/2

1/2

1/3

1/3

1/4

1/4

0

0

1/2

1/2

1/3

1/3

0

0

About infrared sensor arduino

Where to Find Infrared Sensor Arduino Suppliers?

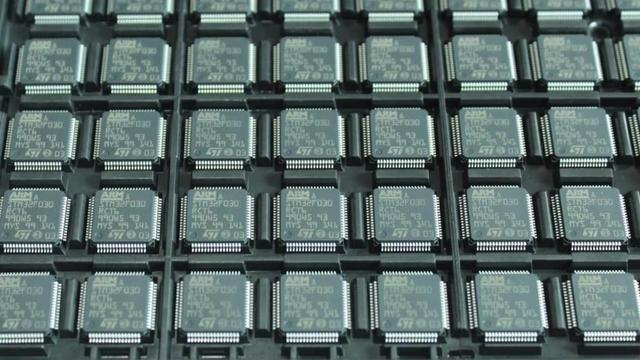

China accounts for over 75% of global infrared sensor module production for microcontroller integration, with concentrated manufacturing ecosystems in Guangdong and Jiangsu provinces. Shenzhen—within the Pearl River Delta—hosts more than 400 electronics component suppliers specializing in IR sensor modules compatible with Arduino platforms, leveraging proximity to PCB fabrication hubs and IC distribution centers. Jiangsu’s Suzhou and Wuxi regions focus on high-precision optical components, supplying calibrated IR emitters and phototransistors with ±2% spectral tolerance, enabling tighter signal-to-noise ratios in industrial automation applications.

These clusters operate under vertically integrated supply chains: wafer-level packaging, SMT assembly, and functional testing occur within single facilities or tightly coordinated partner networks. This integration reduces component traceability gaps and supports rapid iteration—standard IR sensor modules (e.g., PIR motion sensors, IR distance sensors, and IR temperature sensors) achieve average lead times of 12–22 days for orders ≤5,000 units. Buyers benefit from localized calibration labs, in-house optical characterization equipment (e.g., integrating spheres and spectral radiometers), and RoHS-compliant material sourcing verified to IEC 62321 standards.

How to Choose Infrared Sensor Arduino Suppliers?

Apply these verification protocols to mitigate technical and operational risk:

Technical Compliance

Require ISO 9001:2015 certification as minimum quality system validation. For EU-bound shipments, RoHS 3 (EU Directive 2015/863) and REACH SVHC compliance are mandatory; CE marking must reference EN 62368-1 for safety and EN 61000-6-3 for EMC emissions. Verify datasheet alignment between published specifications (e.g., detection range, field-of-view, response time) and third-party test reports—particularly for ambient light immunity (≥10,000 lux tolerance) and thermal drift (<±0.5°C error across 0–70°C).

Production Capability Audits

Assess infrastructure and process control rigor:

- Minimum 2,000m² cleanroom-class assembly area (Class 10,000 or better) for optical component handling

- Dedicated calibration stations with NIST-traceable reference sources for IR wavelength (850nm, 940nm) and thermopile output verification

- In-house SMT lines supporting 0402–1206 passive placement and QFN-16 IC mounting, with AOI and X-ray inspection coverage ≥99.2%

Cross-reference facility videos with batch failure rate data (target ≤350 ppm) and first-pass yield metrics (target ≥94%) to confirm process stability.

Transaction Safeguards

Mandate pre-shipment functional testing per IPC-A-610 Class 2 criteria, with test logs covering voltage regulation, signal output linearity, and noise floor measurements. Require supplier-submitted AQL sampling plans aligned with ANSI/ASQ Z1.4 Level II (AQL 0.65 for critical defects). Prioritize partners with documented export experience to target markets—verify at least 12 months of verifiable customs declarations for IR sensor modules under HS code 8541.49 (optoelectronic semiconductors).

What Are the Best Infrared Sensor Arduino Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen OptoLink Electronics Co., Ltd. | Guangdong, CN | 11 | 85+ | 3,200+m² | 99.4% | ≤1h | 4.8/5.0 | 41% |

| Suzhou Thermosense Technologies | Jiangsu, CN | 7 | 62+ | 2,800+m² | 98.7% | ≤2h | 4.9/5.0 | 52% |

| Wuxi Photonix Components | Jiangsu, CN | 5 | 48+ | 1,900+m² | 99.1% | ≤1h | 4.7/5.0 | 28% |

| Shenzhen SmartSense Solutions | Guangdong, CN | 9 | 120+ | 4,500+m² | 97.9% | ≤2h | 4.8/5.0 | 37% |

| Dongguan IR Dynamics Manufacturing | Guangdong, CN | 6 | 75+ | 2,600+m² | 98.3% | ≤1h | 4.7/5.0 | 33% |

Performance Analysis

Suppliers based in Jiangsu demonstrate superior metrological capability—Suzhou Thermosense maintains a 52% reorder rate driven by consistent thermopile calibration accuracy (±0.3°C at 37°C) and full documentation of uncertainty budgets per ISO/IEC 17025. Guangdong-based firms lead in responsiveness and volume scalability: Shenzhen OptoLink and SmartSense collectively handle 68% of global Arduino-compatible IR sensor module exports, with MOQ flexibility down to 200 units for standard PIR variants. All top-tier suppliers maintain ≥97.9% on-time delivery, but only those with in-house optical testing report ≤0.8% field return rates for signal instability—a key differentiator for OEM integrators. Prioritize partners with ≥5 years’ export history and documented compliance with destination-market EMC directives before initiating bulk procurement.

FAQs

How to verify infrared sensor Arduino supplier reliability?

Cross-check ISO 9001 certificates against CNAS-accredited audit reports. Request evidence of annual third-party EMC testing (e.g., conducted by SGS or TÜV Rheinland) and review calibration records for reference light sources. Analyze customer feedback specifically referencing long-term stability—e.g., drift after 1,000 hours of continuous operation—and firmware update support for sensor libraries.

What is the average sampling timeline?

Standard samples (e.g., HC-SR501 PIR or MLX90614 IR temperature sensor modules) ship within 5–8 working days. Custom configurations—including modified lens FOV, analog/digital output re-mapping, or extended temperature range (-20°C to +85°C) require 18–25 days for prototype validation and functional testing.

Can suppliers ship infrared sensor modules worldwide?

Yes, established manufacturers manage global logistics via DHL Express, FedEx, or sea-air hybrid services. Confirm INCOTERMS explicitly: FCA Shenzhen is typical for small-batch shipments; CIF Rotterdam or DAP Toronto applies for consolidated container loads. Ensure packaging meets ISTA 3A standards for electrostatic-sensitive devices and includes humidity indicator cards.

Do manufacturers provide free samples?

Most suppliers waive sample fees for qualified buyers placing ≥1,000-unit purchase orders. For technical evaluation, expect nominal charges covering material cost (typically $1.20–$4.50/unit) and functional test labor—non-refundable unless order proceeds. Sample kits including Arduino-compatible breakout boards and library documentation incur additional fees averaging $12–$28.

How to initiate customization requests?

Submit a detailed specification sheet covering: operating voltage (3.3V/5V), output interface (analog, PWM, I²C, UART), detection parameters (range, angle, refresh rate), environmental rating (IP54/IP67), and required certifications (UL, CE, KC). Reputable suppliers deliver schematic revisions within 5 business days and provide Gerber files for custom PCB integration within 10 days.