Arduino With Temperature Sensor

Top sponsor listing

Top sponsor listing

1/8

1/8

0

0

1/3

1/3

1/3

1/3

1/4

1/4

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/51

1/51

1/15

1/15

0

0

1/2

1/2

1/3

1/3

0

0

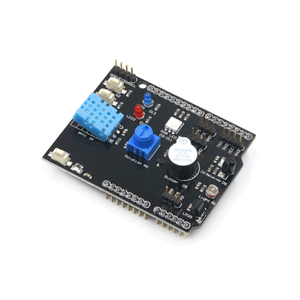

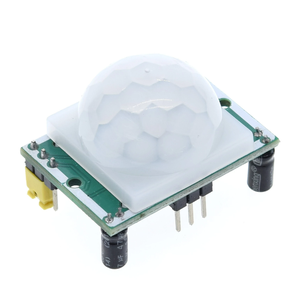

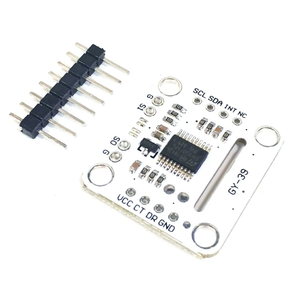

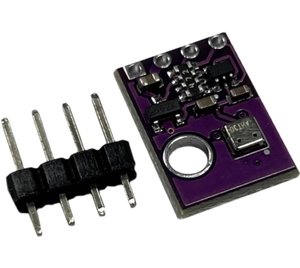

About arduino with temperature sensor

Where to Find Arduino with Temperature Sensor Suppliers?

China remains the central hub for electronics manufacturing, particularly in the development and production of microcontroller-based solutions such as Arduino-compatible systems integrated with temperature sensors. Key industrial clusters are concentrated in Guangdong and Zhejiang provinces, where Shenzhen’s advanced electronics ecosystem provides rapid prototyping, component sourcing, and scalable assembly capabilities. Over 70% of global low-to-mid-range embedded sensor modules originate from this region, supported by dense networks of PCB fabricators, firmware developers, and logistics providers.

These regions offer vertically integrated supply chains that streamline production from design to delivery. Suppliers benefit from proximity to semiconductor distributors, SMT (surface-mount technology) lines, and calibration laboratories, enabling efficient batch processing and customization. Buyers gain access to flexible manufacturing models—supporting both small-batch development runs and high-volume OEM orders—with average lead times ranging from 15 to 30 days for standard configurations. Cost efficiencies are notable, with localized sourcing reducing bill-of-materials (BOM) expenses by 20–35% compared to equivalent Western or Southeast Asian producers.

How to Choose Arduino with Temperature Sensor Suppliers?

Procurement decisions should be guided by systematic evaluation criteria to ensure technical reliability and supply chain integrity:

Quality Management Compliance

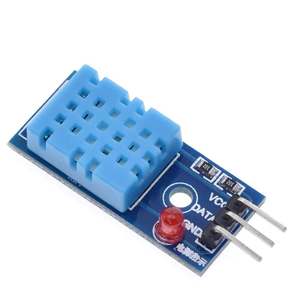

Confirm adherence to ISO 9001 standards for consistent production processes. For export to regulated markets (EU, North America), verify compliance with RoHS (Restriction of Hazardous Substances) and CE marking requirements. Request test reports validating sensor accuracy (±0.5°C tolerance for common models like DS18B20 or DHT22) and long-term stability under thermal cycling.

Technical Production Capacity

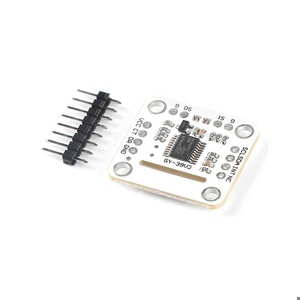

Assess supplier infrastructure based on the following benchmarks:

- Minimum 2,000m² facility with dedicated SMT and testing zones

- In-house programming and firmware flashing capabilities

- Automated optical inspection (AOI) systems for PCB quality control

Cross-reference production capacity with order volume needs—suppliers handling over 10,000 units/month typically maintain stable component inventories and shorter ramp-up times.

Transaction and Quality Assurance Protocols

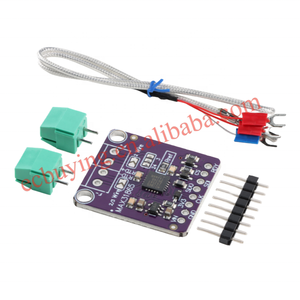

Utilize secure payment methods such as third-party escrow services until product verification is complete. Prioritize suppliers offering pre-shipment sample testing and detailed documentation, including Gerber files, BOM breakdowns, and calibration certificates. Conduct functional validation against specified operating ranges (e.g., -40°C to +125°C for industrial-grade sensors) before scaling procurement.

What Are the Best Arduino with Temperature Sensor Suppliers?

No verified supplier data is currently available for Arduino with temperature sensor manufacturers meeting minimum benchmark thresholds for facility size, operational history, and verifiable performance metrics. In the absence of structured supplier profiles, buyers must initiate direct due diligence through factory audits, prototype sampling, and certification verification.

Performance Analysis

Without published performance data, risk mitigation becomes critical. Focus on suppliers demonstrating transparency in technical specifications, responsive communication (target response time ≤4 hours), and documented experience in exporting electronic modules. Preference should be given to entities with at least two years of operational history, proven order fulfillment records, and demonstrated capability in firmware customization and sensor calibration. Video audits of production lines and real-time testing demonstrations can serve as proxies for formal performance ratings.

FAQs

How to verify Arduino with temperature sensor supplier reliability?

Validate certifications through official databases (e.g., EU NANDO for CE). Request third-party inspection reports from agencies such as SGS or TÜV for batch-produced units. Evaluate supplier credibility via customer references, shipment tracking history, and consistency in labeling and packaging standards.

What is the average sampling timeline?

Standard sample generation takes 7–14 days, depending on component availability and customization level. Fully programmed and calibrated units with labeled pinouts and user documentation typically require up to 10 working days. Air shipping adds 5–8 days for international delivery.

Can suppliers ship Arduino with temperature sensor units worldwide?

Yes, most established electronics manufacturers support global distribution via air or sea freight. Confirm Incoterms (FOB Shenzhen, CIF Rotterdam, etc.) and ensure compliance with import regulations related to electronic components in destination countries. Electrostatic discharge (ESD)-safe packaging is standard for bulk shipments.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers offer one complimentary unit for qualified buyers committing to minimum order quantities (MOQ ≥500 units). Otherwise, expect to pay a nominal fee covering material and labor costs (typically $15–$30 per unit), refundable upon order confirmation.

How to initiate customization requests?

Submit detailed technical requirements including microcontroller type (ATmega328P, ESP32, etc.), sensor model (DS18B20, TMP36, etc.), power input (3.3V/5V), PCB dimensions, and firmware logic (e.g., I2C vs. One-Wire protocol). Reputable suppliers respond with schematic reviews within 48 hours and deliver custom prototypes within 3–4 weeks.