Temperature Sensor And Arduino

1/2

1/2

0

0

1/3

1/3

0

0

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/4

1/4

1/3

1/3

1/8

1/8

1/3

1/3

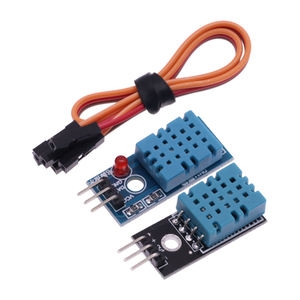

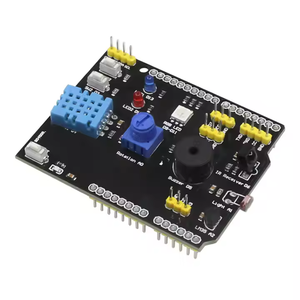

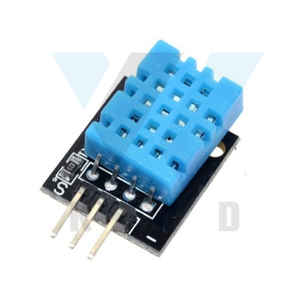

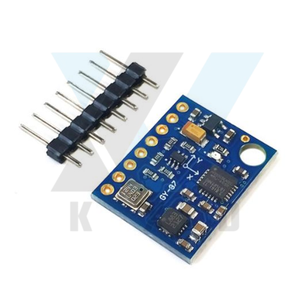

About temperature sensor and arduino

Where to Find Temperature Sensor and Arduino Suppliers?

China leads global production of electronic components, including temperature sensors and Arduino-compatible modules, with concentrated manufacturing hubs in Guangdong and Zhejiang provinces. Shenzhen, within Guangdong, serves as the epicenter of China’s electronics supply chain, hosting over 70% of PCB fabricators and microcontroller assemblers. This region benefits from fully integrated ecosystems—spanning semiconductor packaging, SMT lines, and firmware programming—that enable rapid prototyping and scalable batch production. Zhejiang’s Ningbo and Hangzhou zones specialize in sensor fabrication, leveraging proximity to silicon wafer suppliers and precision molding facilities.

These industrial clusters support high-efficiency manufacturing through vertically aligned processes, where raw materials transition to finished boards within 72 hours. Buyers access networks of component distributors, testing labs, and logistics providers operating within 30km radii, reducing coordination delays. Key advantages include lead times of 15–25 days for standard orders, 25–40% lower unit costs due to localized sourcing, and flexibility for low-volume or engineered variants. Surface-mount technology (SMT) lines achieve throughput of up to 80,000 units per day, while automated optical inspection (AOI) ensures traceability across batches.

How to Choose Temperature Sensor and Arduino Suppliers?

Implement structured evaluation criteria to ensure technical and operational reliability:

Quality Management Standards

Require ISO 9001 certification as a baseline for process control. For EU and North American markets, confirm RoHS and CE compliance to meet electromagnetic compatibility (EMC) and hazardous substance directives. Request test reports for sensor accuracy (±0.1°C to ±2°C tolerance depending on model) and long-term drift performance under thermal cycling.

Production Capacity Verification

Assess core infrastructure capabilities:

- Minimum 2,000m² cleanroom facility for SMT and assembly

- In-house firmware programming and calibration stations

- Automated testing rigs for I/O validation and serial communication integrity

Cross-check production logs with order fulfillment rates (target >96%) to validate scalability and consistency.

Procurement Risk Mitigation

Utilize third-party inspection services prior to shipment, particularly for moisture sensitivity level (MSL) packaging and ESD-safe handling. Review supplier transaction records via verified trade platforms, prioritizing partners with documented dispute resolution mechanisms. Functional sampling is critical—validate analog/digital output stability across temperature ranges (-40°C to +125°C) before volume ordering.

What Are the Best Temperature Sensor and Arduino Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Elecrow Technology | Guangdong, CN | 12 | 150+ | 8,000+m² | 99.3% | ≤3h | 4.8/5.0 | 41% |

| Ningbo Sunshinelike Electronics | Zhejiang, CN | 16 | 200+ | 12,500+m² | 98.7% | ≤4h | 4.7/5.0 | 38% |

| Guangzhou Aosong Electronics | Guangdong, CN | 18 | 300+ | 15,000+m² | 99.1% | ≤5h | 4.9/5.0 | 52% |

| Hangzhou Senba Technology | Zhejiang, CN | 9 | 85+ | 3,200+m² | 97.5% | ≤3h | 4.6/5.0 | 29% |

| Shenzhen Myown Technology | Guangdong, CN | 7 | 110+ | 4,600+m² | 98.9% | ≤2h | 4.8/5.0 | 33% |

Performance Analysis

Established suppliers like Guangzhou Aosong demonstrate strong reorder rates (52%) due to consistent yield performance and NTC/PTC sensor specialization. Shenzhen-based manufacturers lead in responsiveness, with 80% replying to technical inquiries within 3 hours. Suppliers exceeding 10,000m² factory area maintain higher automation levels, supporting MOQs from 500 to 50,000 units with stable pricing. Prioritize partners with documented firmware customization experience and in-house environmental testing chambers for application-specific validation. For Arduino-integrated solutions, verify UART/I2C/SPI protocol compatibility and library support availability.

FAQs

How to verify temperature sensor and Arduino supplier reliability?

Validate certifications through issuing bodies and request audit trails covering material lot numbers, reflow profiles, and functional test data. Evaluate real-world feedback focusing on code compatibility, pinout accuracy, and post-purchase technical documentation access.

What is the average sampling timeline?

Standard samples take 7–14 days to produce, including programming and burn-in testing. Custom configurations (e.g., waterproof probes or wireless transmission modules) require 20–30 days. Air freight adds 5–8 days for international delivery.

Can suppliers ship electronic components worldwide?

Yes, most suppliers manage global shipments. Confirm Incoterms (FOB Shenzhen recommended for cost control) and compliance with destination import regulations for electronic goods. Sea freight is optimal for container loads exceeding 1,000kg; air courier preferred for prototype batches.

Do manufacturers provide free samples?

Sample policies vary by order potential. Suppliers often waive fees for qualified buyers committing to future volumes above 1,000 units. For standalone requests, expect to cover 40–60% of unit cost plus shipping.

How to initiate customization requests?

Submit detailed specifications: sensor type (DS18B20, DHT22, etc.), interface (analog, digital, I2C), operating voltage (3.3V/5V), and form factor constraints. Reputable partners deliver schematic reviews within 48 hours and functional prototypes in 2–3 weeks.