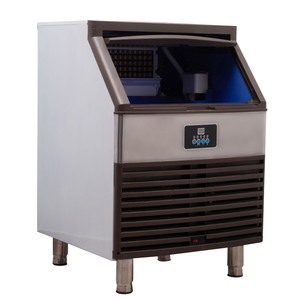

Under Counter Ice Maker Machine

CN

CN

About under counter ice maker machine

Where to Find Under Counter Ice Maker Machine Suppliers?

China remains the global epicenter for under counter ice maker machine manufacturing, with key production clusters in Guangdong, Jiangmen, and Shandong provinces. These regions host vertically integrated supply chains specializing in commercial refrigeration equipment, enabling cost-efficient production and rapid scaling. Guangzhou and Jiangmen are recognized for stainless steel fabrication and advanced cooling system integration, while Shandong’s industrial base excels in precision sheet metal processing and OEM/ODM assembly.

The concentration of component suppliers—compressors, evaporators, condensers, and control systems—within 50–100km radii reduces logistics overhead and accelerates lead times. Facilities typically operate automated production lines capable of producing 80–200 units per month per model, with standard configurations delivered in 30–45 days. Buyers benefit from localized ecosystems offering 20–30% lower unit costs compared to Western manufacturers, particularly for bulk orders exceeding 50 units.

How to Choose Under Counter Ice Maker Machine Suppliers?

Procurement decisions should be guided by rigorous evaluation criteria to ensure product reliability and supply chain stability:

Technical Compliance & Certifications

Verify compliance with international safety and performance standards. CE certification is essential for European market access, while UL or ETL listing may be required for North American distribution. Confirm adherence to ISO 9001 for quality management and assess RoHS compliance for environmental regulations. Request test reports on compressor efficiency, energy consumption (kWh/24h), and daily ice yield accuracy.

Production and Customization Capabilities

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum factory area of 3,000m² for consistent output

- In-house capabilities in sheet metal forming, welding, foam insulation injection, and final assembly

- Customization options including cabinet dimensions, ice type (cube, nugget, crescent), storage capacity, and front panel finishes (stainless steel, coated steel)

- Ability to modify voltage (110V/220V), plug types, and water inlet configurations (single/dual inlet)

Cross-reference online transaction data with on-time delivery rates above 95% and response times under 7 hours to validate operational responsiveness.

Quality Assurance and Transaction Security

Prioritize suppliers with documented quality control protocols at incoming material inspection, in-process checks, and final testing stages. Demand third-party inspection acceptance (e.g., SGS, BV) prior to shipment. Utilize secure payment mechanisms such as escrow services to mitigate risk. Conduct pre-shipment audits to verify ice production capacity, noise levels (dB), and condensation performance under continuous operation.

What Are the Best Under Counter Ice Maker Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order (Units) | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Universal Venture Holding Co., Ltd | Guangdong, CN | Ice Machines, Refrigeration Equipment | US $190,000+ | 100% | ≤7h | 33% | 1–2 | $400–$2,890 |

| Jiangmen Pro-Taylor Refrigeration Co., Ltd. | Guangdong, CN | Custom Ice Makers, Dual Water Inlet Models | US $140,000+ | 96% | ≤3h | 18% | 1–10 | $269–$1,555 |

| Tianbuer Import and Export (Shandong) Co., LTD. | Shandong, CN | Commercial Ice Machines, Stainless Steel Units | US $10,000+ | 80% | ≤1h | 28% | 1 | $160–$1,660 |

| Suzhou Seitek Co., Ltd. | Jiangsu, CN | Electric Cube Makers, Front-Ventilation Designs | Not disclosed | 100% | ≤21h | Not available | 80–198 | $310–$490 |

| Zhongji (Shandong) Metal Products Co., Ltd. | Shandong, CN | Commercial Stainless Steel Units | US $280,000+ | 98% | ≤2h | <15% | 2–8 | $179–$957 |

Performance Analysis

Guangzhou Universal Venture stands out with a 100% on-time delivery rate and mid-range pricing, making it suitable for buyers prioritizing reliability. Jiangmen Pro-Taylor offers strong customization capabilities—including dual water inlets and sensor-based filling—paired with fast response times, ideal for specialized commercial applications. Zhongji (Shandong) leads in volume export performance with US $280,000+ in online revenue and high delivery consistency, though its reorder rate suggests room for customer retention improvement. Suzhou Seitek targets large-volume buyers with MOQs exceeding 80 units, providing competitive pricing but limited flexibility. Tianbuer offers the lowest entry price point ($160), but its 80% on-time delivery rate indicates potential fulfillment risks requiring closer oversight.

FAQs

What is the typical MOQ for under counter ice maker machines?

MOQ varies significantly: most suppliers require 1–10 units for standard models, while some low-cost manufacturers set MOQs at 80–200 units to optimize container loading. Buyers seeking small trial orders should prioritize suppliers with 1-unit MOQs.

What are common lead times after order confirmation?

Standard production lead time ranges from 25–40 days, depending on order size and customization level. Air freight samples can arrive within 7–12 days globally, while sea freight takes 20–35 days depending on destination port.

Can suppliers customize ice production capacity and dimensions?

Yes, most verified custom manufacturers offer modifications to width (typically 20–35 inches), height, depth, and daily output (ranging from 50kg to 500kg). Engineering teams can adjust evaporator plates, compressor types, and bin capacities upon request.

Do suppliers provide technical documentation and installation guides?

Reputable suppliers include multilingual user manuals, electrical schematics, and plumbing diagrams. Some offer remote support via video call for initial setup, especially for commercial kitchen deployments.

Are there options for private labeling and branding?

Yes, many suppliers support OEM/ODM services, including custom logos, color finishes, packaging design, and branded control panels. Minimum branding quantities typically start at 10–50 units depending on complexity.