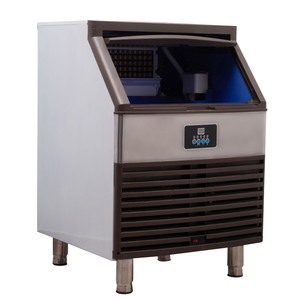

Under Counter Ice Maker With Dispenser

CN

CN

About under counter ice maker with dispenser

Where to Find Under Counter Ice Maker with Dispenser Suppliers?

China remains the dominant manufacturing hub for under counter ice makers with dispensers, with key production clusters concentrated in Shanghai, Guangdong, and Henan provinces. These regions host vertically integrated supply chains encompassing compressor fabrication, refrigeration system assembly, and stainless steel fabrication—enabling cost efficiencies of 20–35% compared to Western or Southeast Asian manufacturers. Shanghai and Foshan serve as primary export centers due to proximity to major ports and mature industrial ecosystems specializing in commercial kitchen equipment.

Suppliers in these zones benefit from co-located component vendors, including condenser, evaporator, and control module producers, reducing lead times for standard units to 15–30 days. The concentration of engineering talent and automated production lines supports both high-volume OEM contracts and low-volume custom builds. Buyers gain access to flexible manufacturing capabilities, with many facilities equipped for R404a/R290 refrigerant integration, self-cleaning systems, and multi-functional 3-in-1 designs combining ice making, chilling, and dispensing.

How to Choose Under Counter Ice Maker with Dispenser Suppliers?

Procurement decisions should be guided by technical validation, production transparency, and transactional reliability:

Technical & Quality Compliance

Verify adherence to international standards such as CE, RoHS, and ISO 9001. For North American and EU markets, confirm ETL or UL listing eligibility and compliance with energy efficiency regulations. Request performance test reports detailing daily ice yield (ranging from 25kg to 220kg), noise levels (typically 45–55 dB), and power specifications (110V/220V, 50/60Hz).

Production Capacity Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum factory area exceeding 2,000m² for sustained output

- In-house refrigeration system assembly and leak testing protocols

- Stainless steel fabrication capabilities (SUS304 standard) with TIG welding

Cross-reference online revenue data and on-time delivery rates (>97%) to assess operational stability and order fulfillment consistency.

Transaction & Risk Mitigation

Utilize secure payment mechanisms such as escrow or Trade Assurance for initial orders. Prioritize suppliers with documented quality control processes—including pre-shipment inspections and third-party lab testing. Request physical or digital samples to validate build quality, dispensing mechanism reliability, and insulation performance before scaling procurement.

What Are the Best Under Counter Ice Maker with Dispenser Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Flexibility | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| JELUMB Refrigeration Equipment (Shanghai) Co., Ltd. | Shanghai, CN | Ice Machines, Commercial Ice Cream Machines, Juice Extractors | US $80,000+ | 100% | ≤9h | <15% | 1 set | $920–2,420 |

| Foshan Libosa Hotel Suppliers Co., Ltd. | Foshan, Guangdong, CN | Refrigeration Equipment, Hotel & Restaurant Supplies, Baking Ovens | US $150,000+ | 100% | ≤2h | 20% | 1 set/piece | $356–1,269 |

| Shanghai Snowman Electrical Equipment Co., Ltd. | Shanghai, CN | Ice Machines | US $10,000+ | 100% | ≤6h | <15% | 1–2 pieces | $405–1,000 |

| Zhengzhou Baopin Machinery Co., Ltd. | Zhengzhou, Henan, CN | Ice Machines, Ice Crushers, Espresso Machines, Water Purifiers | US $30,000+ | 100% | ≤2h | 50% | 1 set | $729–1,299 |

| Yuyao Haohong Electrical Appliance Co., Ltd. | Ningbo, Zhejiang, CN | Compact Refrigerators, Ice Makers, Home Appliances | US $180,000+ | 100% | ≤2h | <15% | 1–100 pieces | $66.90–150 |

Performance Analysis

Foshan Libosa and Zhengzhou Baopin stand out for rapid response times (≤2h) and robust reorder activity, indicating strong buyer satisfaction. Yuyao Haohong offers the lowest price points, targeting budget-conscious buyers with compact, residential-grade models, while JELUMB and Baopin focus on higher-capacity commercial units priced above $900. Suppliers like Foshan Libosa and Shanghai Snowman provide broad refrigerant compatibility and modular designs suitable for integration into beverage counters. Buyers seeking high-volume reliability should prioritize partners with proven export experience and in-house R&D teams capable of supporting customization, such as dual-dispensing mechanisms or reduced footprint configurations.

FAQs

How to verify under counter ice maker supplier reliability?

Confirm certifications through official databases and request factory audit reports or video walkthroughs. Analyze transaction history, focusing on consistent on-time delivery and verifiable customer reviews related to after-sales service and product durability.

What is the typical lead time for bulk orders?

Standard orders require 15–30 days for production and packaging. Custom configurations involving unique dimensions or refrigerants may extend lead times to 45 days. Air freight delivers in 5–10 days; sea freight takes 20–35 days depending on destination port.

Do suppliers support OEM/ODM customization?

Yes, most suppliers listed offer OEM labeling, color finishes, and control panel modifications. Minimum order quantities for branding typically start at 50 units. ODM development requires technical drawings and may involve NRE (non-recurring engineering) fees.

What are common MOQ and pricing structures?

MOQs range from 1 piece for sample testing to 100 pieces for wholesale pricing. Unit costs decrease significantly at 10+ units, especially for modular or compact models. Commercial-grade units maintain stable pricing even at low volumes due to specialized components.

How to evaluate ice maker performance before procurement?

Request test data on ice production rate, storage capacity, energy consumption (kWh/24h), and noise level. Conduct sample trials to assess water dispensing accuracy, bin accessibility, and cleaning cycle effectiveness. Validate compatibility with local voltage and water pressure conditions.