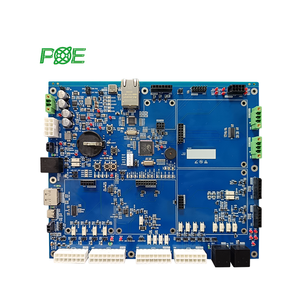

Advanced Circuit Board

CN

CN

CN

CN

About advanced circuit board

Where to Find Advanced Circuit Board Suppliers?

China remains the global epicenter for advanced circuit board manufacturing, with Shenzhen and Guangzhou serving as primary hubs due to concentrated electronics supply chains and specialized technical labor pools. Shenzhen alone accounts for over 50% of China’s PCB & PCBA production capacity, supported by mature ecosystems integrating component sourcing, SMT assembly, testing, and logistics within compact industrial zones. This clustering enables rapid prototyping cycles—often under 7 days for multilayer boards—and reduces material procurement lead times by 25–40% compared to non-specialized regions.

Suppliers in these zones operate vertically integrated facilities capable of handling rigid, flex, HDI, and rigid-flex circuit boards up to 20+ layers. Local access to FR4, high-frequency laminates (e.g., Rogers), and copper-clad substrates ensures consistent material availability. The proximity of EMS providers, design houses, and testing labs within 10–30 km radii supports agile development and fast turnaround for both low-volume prototypes and high-volume production runs. Buyers benefit from scalable output, with leading suppliers reporting monthly capacities exceeding 50,000 units across diverse configurations.

How to Choose Advanced Circuit Board Suppliers?

Effective supplier selection requires rigorous evaluation across three core dimensions:

Technical Capability Verification

Confirm support for required fabrication technologies: multilayer stacking (8–20+ layers), HDI with microvias, impedance control, blind/buried vias, and surface finishes (ENIG, OSP, HASL). For high-reliability applications, verify in-house X-ray inspection, AOI, and ICT testing capabilities. Design for manufacturability (DFM) analysis should be standard practice before production initiation.

Quality Assurance Protocols

Prioritize suppliers adhering to IPC-6012 Class 2/3 standards and ISO 9001-certified quality management systems. Environmental compliance (RoHS, REACH) is mandatory for export markets. Evaluate defect rates through historical data—top-tier suppliers maintain field failure rates below 200 PPM. On-time delivery performance above 95% indicates reliable operational execution.

Customization and Transaction Security

Assess flexibility in material selection, layer count, finish type, and component sourcing. Leading suppliers offer full turnkey services including BOM sourcing, stencil creation, and functional testing. Use secure payment mechanisms such as trade assurance or escrow to mitigate risk. Sample validation is critical—request first-article inspections (FAI) and test reports before scaling to mass production.

What Are the Best Advanced Circuit Board Suppliers?

| Company Name | Location | Verified Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (Unit) |

|---|---|---|---|---|---|---|---|---|---|

| Shenzhen Wanfeng Technology Co., Ltd. | Shenzhen, CN | Custom Manufacturer | Rigid-Flex, UAV PCBA, Smart Electronics | US $420,000+ | 100% | ≤1h | 66% | 1–10 pcs | $0.58–3.60 |

| Shenzhen Lihua Technology Co., Ltd. | Shenzhen, CN | - | Multilayer PCB, PCBA, Camera Modules | US $730,000+ | 93% | ≤6h | 36% | 1–10 pcs | $0.09–10.00 |

| Guangzhou Leizzi Electronic Technology Co., Ltd. | Guangzhou, CN | - | HDI, Rigid-Flex, High Frequency PCB | Not disclosed | 100% | ≤3h | No data | 1 pc | $0.50–2.90 |

| Shenzhen Linghangda Technology Co., Ltd. | Shenzhen, CN | Multispecialty Supplier | FR4, EMS, Custom Design Services | US $3,000+ | 100% | ≤9h | <15% | 1 pc | $0.30–1.00 |

| Guangzhou Lingfeite Electronics Co., Ltd. | Guangzhou, CN | - | Vending Machine PCB, Development Boards | US $30,000+ | 100% | ≤2h | 15% | 1 pc | $30.00 |

Performance Analysis

Shenzhen-based suppliers dominate in responsiveness and customization depth, with Shenzhen Wanfeng achieving a 66% reorder rate—indicating strong customer satisfaction—supported by sub-one-hour response times and flexible MOQs starting at one piece. Shenzhen Lihua stands out for revenue scale (over $730,000 online) and broad technical scope, though its 93% on-time delivery rate warrants further due diligence into logistical consistency. Guangzhou Leizzi offers competitive pricing and supports advanced HDI and high-frequency boards, making it suitable for specialized RF and power applications despite limited reorder metrics. Linghangda provides cost-effective solutions at $0.30/unit minimum but shows lower transaction volume and slower response cycles. Lingfeite’s uniform $30 pricing suggests niche focus on complete washer control boards rather than raw PCBs, limiting comparability for general sourcing.

FAQs

What certifications should advanced circuit board suppliers have?

Essential certifications include ISO 9001 for quality management and IPC-6012 compliance for performance class adherence. For EU exports, RoHS and REACH declarations are mandatory. UL listing may be required for safety-critical end-use applications. While not always listed, adherence to IATF 16949 is advantageous for automotive-grade assemblies.

What is the typical lead time for custom circuit boards?

Standard lead times range from 5–7 days for simple 2–4 layer boards to 12–18 days for complex multilayer or HDI designs requiring sequential lamination. Rush services are available at premium rates, reducing turnaround to 3–5 days. Add 3–7 days for PCBA when components require sourcing.

Can suppliers handle small batch orders and prototypes?

Yes, most suppliers accommodate prototype and low-volume orders with MOQs as low as one unit. Shenzhen Wanfeng, Leizzi, and Linghangda all support single-piece orders, enabling cost-effective testing and iterative design validation prior to volume scaling.

Do suppliers offer design and engineering support?

Leading suppliers provide free DFM checks and layout optimization guidance. Some, like Shenzhen Linghangda, explicitly list professional circuit design services. Buyers should confirm availability of Gerber review, impedance calculation, and stack-up planning before order placement.

How are quality issues resolved post-delivery?

Reputable suppliers accept returns or rework for defects traceable to fabrication or assembly errors. Clear warranty terms—typically covering workmanship for 90–365 days—should be established upfront. Third-party inspection services can be arranged pre-shipment for high-value contracts.