Advanced Circuits 4pcb Com

CN

CN

About advanced circuits 4pcb com

Where to Source Advanced Circuits (4PCB) Suppliers?

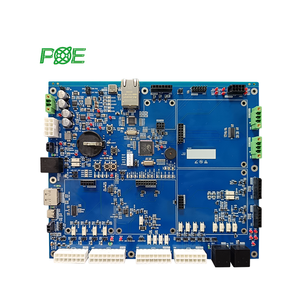

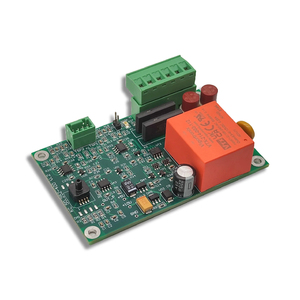

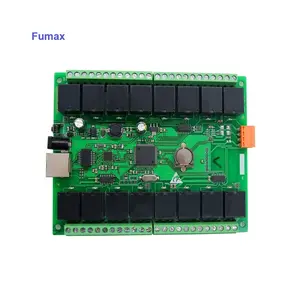

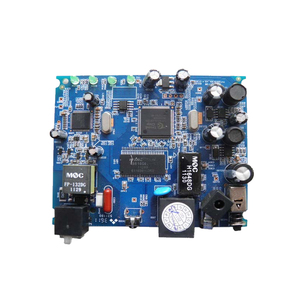

China remains the global epicenter for advanced printed circuit board (PCB) manufacturing, with key production hubs in Guangdong and Zhejiang provinces driving innovation and scale. These regions host vertically integrated facilities specializing in multilayer, high-frequency, rigid-flex, and HDI PCBs—core components under the "advanced circuits 4pcb" category. Guangzhou, Shenzhen, and Huizhou clusters leverage proximity to semiconductor suppliers and SMT assembly lines, enabling streamlined prototyping and volume production.

The industrial ecosystem supports rapid turnaround through localized material sourcing, including FR4, Rogers, and aluminum substrates, reducing lead times by 20–30% compared to offshore alternatives. Suppliers in these zones typically operate automated fabrication lines capable of producing 4-layer to 20+ layer boards with precision impedance control and blind/buried vias. Average monthly output ranges from 10,000 to over 100,000 units depending on complexity, supporting both low-volume engineering samples and high-volume OEM contracts.

How to Evaluate Advanced Circuits (4PCB) Suppliers?

Effective supplier selection requires rigorous assessment across technical, operational, and transactional dimensions:

Technical & Process Capabilities

Verify expertise in critical technologies: multilayer lamination (≥4 layers), high-frequency materials (Rogers, Taconic), and surface finishes such as immersion gold or ENIG. Confirm minimum trace width/spacing capabilities (typically 3–5 mil) and drill accuracy (±0.05mm). For rigid-flex designs, assess bonding strength and bend-cycle endurance testing protocols.

Quality Assurance Systems

Prioritize suppliers with documented adherence to international standards:

- RoHS and REACH compliance for environmental safety

- IPC Class 2 or Class 3 certification for reliability-critical applications

- In-line AOI (Automated Optical Inspection), X-ray inspection for BGA/populated boards

- Environmental stress screening (thermal cycling, humidity testing)

Cross-reference claims with available quality metrics—on-time delivery rates ≥98%, response times ≤4 hours, and reorder rates indicating customer retention.

Customization & Scalability Verification

Assess flexibility for design modifications, including Gerber file validation, impedance modeling, and DFM feedback within 24 hours. Confirm support for turnkey services: component sourcing, SMT assembly, testing, and packaging. Evaluate scalability via factory size indicators and order fulfillment thresholds—suppliers handling 100+ piece orders consistently demonstrate better process maturity than those limited to single-unit prototypes.

What Are the Leading Advanced Circuits (4PCB) Suppliers?

| Company Name | Location | Main Products | MOQ Range | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Leizzi Electronic Technology Co., Ltd. | Guangdong, CN | High Frequency PCB (181), Multilayer PCB (137), PCBA (118) | 1 piece | $0.20–2.90 | 100% | ≤3h | - | Color, size, material, logo, packaging |

| Huizhou Lianxiang Electronics Co., Ltd. | Guangdong, CN | Multilayer PCB (68), Double-sided PCB (50), Aluminum PCB (9) | 300 pieces | $0.99–1.24 | 100% | ≤1h | - | Material, thickness, finish |

| Zhejiang Yumo Electronic Technology Co., Ltd. | Zhejiang, CN | OEM Electronics, Power Boards, Consumer PCBs | 1 piece | $0.50–10.00 | 100% | ≤3h | <15% | Color, material, size, logo, label, graphic, packaging |

| Shenzhen UC Industrail Limited | Shenzhen, CN | Rigid-Flex PCB, PCBA, Custom Circuit Assembly | 1 piece | $1.00–10.00 | 100% | ≤4h | 47% | PCB material, design, gerber, firmware, reverse engineering |

| Dongguan Dongxun Precision Technology Co., Ltd. | Dongguan, CN | PCBA (78), Industrial PCB Assembly, Wafer-Level Packaging | 100 pieces | $0.40–200.00 | 100% | ≤4h | - | Turnkey assembly, AOI/X-ray inspected batches |

Performance Analysis

Guangdong-based suppliers dominate in production consistency and response speed, with all five evaluated companies achieving 100% on-time delivery. Shenzhen UC Industrail Limited stands out with a 47% reorder rate—indicating strong client satisfaction—supported by comprehensive customization including reverse engineering and firmware integration. Huizhou Lianxiang offers competitive pricing for mid-volume 4-layer FR4 boards at MOQs starting from 300 units, ideal for cost-sensitive commercial deployments. For prototype-driven development, Guangzhou Leizzi and Zhejiang Yumo provide sub-$1 entry points with no minimum order restrictions, facilitating rapid iteration. Dongguan Dongxun specializes in high-reliability PCBA solutions with advanced inspection systems, suitable for industrial and semiconductor-grade applications requiring batch traceability and AOI/X-ray validation.

FAQs

How to verify advanced circuits (4PCB) supplier credibility?

Request evidence of compliance with RoHS, IPC standards, and internal QA procedures. Analyze response time consistency and on-time delivery records. Review product listings for technical specificity—detailed stack-up descriptions, copper weights, and surface finish types indicate higher professionalism. Video audits of production lines can validate automation levels and cleanroom conditions for sensitive assemblies.

What is the typical lead time for advanced PCBs?

Standard multilayer PCBs (4–8 layers) require 7–12 days for fabrication. Adding SMT assembly extends timelines to 12–18 days. High-frequency or rigid-flex boards may take 15–25 days due to specialized lamination cycles. Expedited services are available at premium rates, reducing delivery to 5–7 days for urgent prototypes.

Do suppliers support small-batch or prototype orders?

Yes, multiple suppliers accept orders starting from 1 piece, particularly for R&D or testing phases. However, unit costs are significantly higher at low volumes. Buyers should evaluate trade-offs between upfront savings (via larger MOQs) and development agility when planning procurement strategy.

Can I request custom materials or impedance control?

Most suppliers accommodate special materials such as Rogers 4350B, Isola, or Arlon for RF/microwave applications. Impedance tolerance down to ±5% is standard with proper stack-up design. Submit detailed specifications including dielectric constant, layer structure, and controlled impedance pairs for accurate quoting.

What are common payment and transaction safeguards?

Standard terms include T/T (bank transfer), with 30–50% deposit for production initiation. Third-party assurance programs help mitigate risk by linking payment release to shipment verification. For initial engagements, consider starting with a pilot order before scaling. Retain rights to inspect samples prior to full production runs.