Automatic Namkeen Making Machine

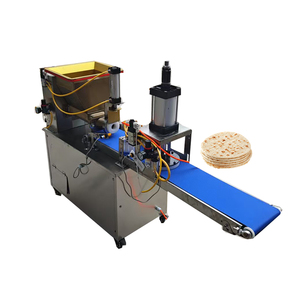

About automatic namkeen making machine

Where to Find Automatic Namkeen Making Machine Suppliers?

China remains the central hub for automated snack food machinery manufacturing, with key production clusters in Henan and Hunan provinces driving innovation and scale in automatic namkeen making machines. These regions host vertically integrated supply chains encompassing stainless steel fabrication, electrical control systems, and food-grade component sourcing, enabling cost efficiencies of 20–35% compared to equivalent machinery produced outside Asia. Zhengzhou and Changsha serve as logistical anchors, offering direct rail and sea freight access that reduces export lead times by up to 18%.

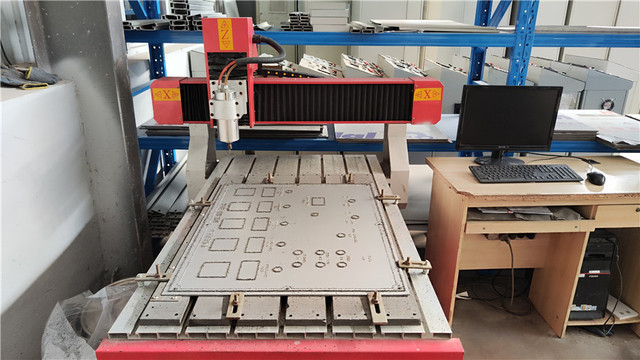

The industrial ecosystem supports both modular and turnkey solutions, from compact single-function units to fully automated frying, seasoning, and packaging lines. Manufacturers leverage localized access to CNC machining, welding automation, and PLC programming resources, allowing rapid prototyping and customization. Buyers benefit from consolidated vendor networks where engineering, testing, and shipping are coordinated within tight geographic proximity—typically under 50km—ensuring faster commissioning cycles and responsive after-sales support.

How to Choose Automatic Namkeen Making Machine Suppliers?

Effective supplier selection requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Confirm adherence to international food safety and equipment standards. Look for CE marking as evidence of compliance with EU mechanical and electrical safety directives. While ISO 9001 certification is not universally listed, prioritize suppliers who document quality management processes, especially those handling export markets. Verify use of food-grade stainless steel (e.g., SUS304) in contact surfaces and IP65-rated electrical enclosures for moisture resistance in high-humidity environments.

Production Capability Assessment

Evaluate supplier capacity based on infrastructure indicators:

- Facility size and specialization in food processing lines or grain product machinery

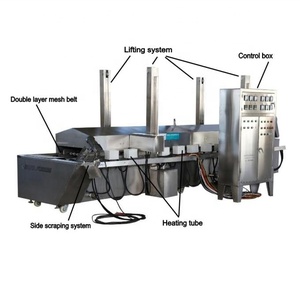

- In-house engineering teams capable of customizing output capacity, frying temperature control, and integration with downstream packaging systems

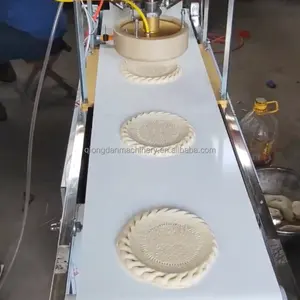

- Proven experience in delivering complete production lines, particularly for extruded snacks like kurkure, nimkis, or shrimp crackers

Cross-reference product listings with response time and on-time delivery metrics—suppliers achieving ≤2-hour response times and ≥93% on-time fulfillment demonstrate operational reliability. High listing volumes in "Other Snack Machines" and "Grain Product Making Machines" indicate domain specialization.

Transaction Security & Procurement Strategy

Utilize secure payment mechanisms such as escrow services to mitigate risk during initial transactions. Request machine performance data including oil circulation efficiency, frying duration control, and energy consumption rates. Conduct video audits of assembly lines to verify build quality before shipment. Prioritize suppliers offering customization options in material finish, color coding, logo branding, and packaging integration for brand-specific production needs.

What Are the Best Automatic Namkeen Making Machine Suppliers?

| Company Name | Main Products (Listings) | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| GELGOOG CO., LTD | Food processing lines (493), Other Snack Machines (337) | $15,990–17,990; up to $250,000–400,000 | 1 set | Data not available | ≤2h | Data not available | Data not available |

| NST TECHNOLOGY LLC | Other Snack Machines (1039), Grain Product Making Machines (555) | $800–1,699 | 1 set | Data not available | ≤3h | Data not available | Data not available |

| Hunan Kangxin Technology Co., Ltd. | Automatic noodle and ramen machines | $98–118; $295–4,199 | 1 set | 93% | ≤2h | 16% | US $290,000+ |

| Zhengzhou Kingdoo Machinery Co., Ltd. | Grain Product Making Machines (346), Food processing lines (306) | $62,000–220,000 | 1 set | 100% | ≤4h | 100% | US $410,000+ |

| Henan Caiguan Trading Co., Ltd. | Grain Product Making Machines (262), Other Snack Machines (254) | $208–2,999 | 1 unit | 100% | ≤3h | <15% | US $20,000+ |

Performance Analysis

Zhengzhou Kingdoo Machinery stands out with a 100% on-time delivery rate and 100% reorder rate, indicating strong customer satisfaction and consistent execution, particularly for large-scale industrial installations priced above $60,000. The company specializes in integrated food processing lines, suggesting capability in end-to-end project delivery. Hunan Kangxin Technology offers mid-range automation with verified responsiveness (≤2h) and measurable online revenue, supporting its position as a reliable mid-tier supplier. GELGOOG CO., LTD lists high-value systems up to $400,000, targeting fully automated instant noodle and fried snack lines, though public performance metrics are limited. NST TECHNOLOGY and Henan Caiguan provide entry-level automation at sub-$2,000 price points, suitable for small producers or pilot operations, but lack verifiable delivery or revenue data. Buyers seeking scalable, certified systems should prioritize suppliers with documented transaction histories and proven line integration experience.

FAQs

What is the typical MOQ and pricing range for automatic namkeen making machines?

Minimum order quantities are typically 1 set across all suppliers. Pricing varies significantly by automation level: basic models start at $98–$900, mid-range industrial units range from $1,200–$4,200, and full-line automated systems (including frying, seasoning, and packaging) reach $60,000–$400,000 depending on throughput and integration complexity.

What lead times should buyers expect?

Standard machines generally require 20–35 days for production and pre-shipment inspection. Customized systems with PLC controls or multi-stage integration may take 45–60 days. Shipping via sea freight adds 15–30 days depending on destination port.

Can suppliers customize machines for specific snack types?

Yes, many suppliers offer configuration options for different dough formulations, shaping dies, frying temperatures, and oil filtration systems. Customization extends to branding, color schemes, voltage specifications (380V/50Hz standard), and integration with existing factory layouts. Video-based design reviews are recommended prior to final approval.

Do manufacturers provide installation and training support?

Support varies by supplier. Higher-tier vendors often include remote guidance or documentation packages. For complex lines, on-site technician deployment may be available at additional cost. Confirm service terms—including language support and spare parts availability—before contract finalization.

Are samples available before bulk orders?

Functional machine samples are rarely provided due to size and cost. However, suppliers can produce sample batches using buyer-specified ingredients and ship them for evaluation. Some vendors offer factory-run demonstrations via live video stream to validate performance parameters.