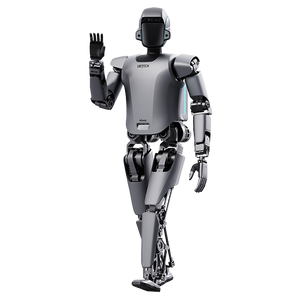

Automation Robotics And The Factory Of The Future

CN

CN

CN

CN

CN

CN

About automation robotics and the factory of the future

Where to Find Automation Robotics and the Factory of the Future Suppliers?

China remains a dominant force in automation robotics manufacturing, with key supplier clusters concentrated in Shandong, Guangdong, and Qingdao regions. These industrial hubs integrate advanced R&D centers with scalable production facilities, enabling rapid deployment of robotic systems for smart factories. Shandong-based suppliers benefit from proximity to heavy industry demand, supporting robust engineering ecosystems for collaborative robots (cobots) and automated guided vehicles (AGVs). Guangdong’s Pearl River Delta region hosts high-tech manufacturers specializing in integrated automation solutions, including laser welding robots and AI-enabled control systems.

The concentration of component suppliers—servo motors, sensors, motion controllers—and machining services within 50km radii allows for vertically integrated production. This localization reduces lead times by up to 30% compared to decentralized supply chains. Buyers gain access to agile manufacturers capable of fulfilling both standard and customized automation systems, with typical delivery windows ranging from 15–45 days depending on complexity. Cost efficiencies are significant, with Chinese suppliers offering 20–40% lower pricing than European or North American counterparts due to optimized labor and logistics structures.

How to Choose Automation Robotics and the Factory of the Future Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Product Range

Verify that suppliers offer ISO 9001-certified production processes as a baseline quality benchmark. For export markets, CE marking is essential for compliance with EU safety directives. Assess product portfolios for alignment with specific automation needs—such as 6-axis industrial arms, AGVs, or welding robots—and confirm availability of integration-ready components like controllers, teaching pendants, and networked I/O modules.

Production Capability Verification

Evaluate infrastructure maturity through objective indicators:

- Minimum factory area exceeding 3,000m² to support assembly lines and testing bays

- In-house capabilities in CNC machining, robotic arm calibration, and electronic control system integration

- Demonstrated customization options: payload variation (3–20kg), arm length adjustments, gripper types, and software programmability (e.g., Lua scripting support)

Cross-reference online revenue data and order fulfillment rates to assess scalability. Prioritize suppliers with documented after-sales service frameworks and remote diagnostic support.

Transaction Safeguards & Quality Assurance

Utilize secure payment mechanisms such as escrow services to mitigate financial risk. Demand performance documentation—including response time logs, on-time delivery records, and reorder rates—for validation. Conduct pre-shipment inspections or request video audits of production lines. Sample testing should include functional verification of robot precision (repeatability ≤±0.02mm), cycle endurance, and controller responsiveness under simulated load conditions.

What Are the Best Automation Robotics and the Factory of the Future Suppliers?

| Company Name | Supplier Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Product Highlights |

|---|---|---|---|---|---|---|---|

| Qingdao Rainbow Technology Co., Ltd. | Multispecialty Supplier | US $1,100,000+ | 90% | ≤1h | 22% | Yes | 6-Axis Mini Robot Arm, Welding Robots, Collaborative Arms with Camera Support |

| Shandong Rayman Machinery Co., Ltd. | Custom Manufacturer | US $40,000+ | 75% | ≤2h | <15% | Yes | Cheapest Collaborative Robots, Flexible Six-Axis Arms, Direct-Sales Models |

| Ae Robotics Co., Ltd. | Multispecialty Supplier | US $40,000+ | 100% | ≤4h | 20% | Yes | ABB-Compatible Industrial Robots, Pick-and-Place Cobots, 4-Axis Universal Robots |

| Guangzhou Koza Robot Engineering Technology Co., Ltd. | Manufacturer | - | 100% | ≤1h | - | No | Laser Welding Robots, Articulated Robotic Arms, Arc Welding Process Packages |

| Guangzhou Wisdom Wheel Science Technology Ltd. | Manufacturer | US $130,000+ | 100% | ≤2h | 42% | No | Forklift AGVs, Smart Delivery Robots, Die-Change Carts, Servo-Driven AGVs |

Performance Analysis

Qingdao Rainbow Technology stands out for high-volume capacity and extensive customization capabilities, supported by strong online sales performance and sub-one-hour response times. Despite a slightly lower on-time delivery rate (90%), its 22% reorder rate indicates consistent customer satisfaction. Guangzhou Wisdom Wheel demonstrates exceptional buyer retention (42% reorder rate), reflecting reliability in AGV manufacturing and after-sales engagement. Ae Robotics achieves perfect on-time delivery and offers technically diverse products, including ABB-integrated systems, though response times lag behind leaders. Guangzhou Koza focuses on high-value welding automation but lacks explicit customization disclosure, making it better suited for standardized deployments. Shandong Rayman offers competitive pricing (from $3,490/set) but has a lower reorder rate, suggesting potential gaps in long-term service delivery.

FAQs

How to verify automation robotics supplier reliability?

Cross-check ISO/CE certifications with issuing bodies and request third-party audit reports covering design validation, component sourcing, and final product testing. Analyze verifiable transaction histories, focusing on dispute resolution outcomes and post-delivery technical support responsiveness.

What is the average lead time for robotic systems?

Standard configurations typically ship within 15–30 days. Customized units requiring software integration or mechanical modifications may require 30–45 days. Express production surcharges can reduce timelines by 30–50% for urgent orders.

Can suppliers provide global shipping and installation support?

Yes, established manufacturers offer FOB and CIF shipping terms with coordination for sea or air freight. Some provide optional on-site commissioning and operator training, particularly for turnkey automation cells. Confirm inclusion of manuals, wiring diagrams, and PLC interface protocols prior to shipment.

Do suppliers offer free samples or trial units?

Sample policies vary. Full-system trials are rarely free but may be offered at reduced cost for qualified buyers placing follow-up bulk orders. Partial demos—such as controller interfaces or single-axis movement tests—are more commonly available at no charge.

How to initiate customization requests for robotic systems?

Submit detailed specifications including required payload (kg), reach (mm), repeatability tolerance, mounting configuration, and control interface (e.g., Ethernet/IP, Modbus TCP). Reputable suppliers respond with technical proposals, 3D models, and integration schematics within 5–7 business days.