Batch Prototyping

0

0

1/24

1/24

1/18

1/18

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/1

1/1

1/3

1/3

CN

CN

1/20

1/20

1/3

1/3

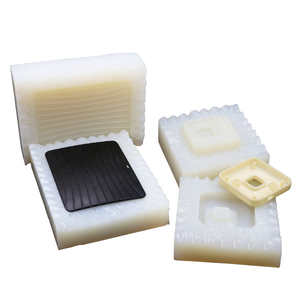

About batch prototyping

Where to Find Batch Prototyping Suppliers?

China leads the global market for batch prototyping services, with key manufacturing clusters in Shenzhen, Dongguan, and Hangzhou offering specialized capabilities in rapid tooling, low-volume production, and advanced material processing. These regions host vertically integrated facilities that combine CNC machining, 3D printing (SLA/DLP), vacuum casting, and silicone molding under one roof, enabling seamless transitions from prototype to small-batch manufacturing. Shenzhen and Dongguan stand out for electronics-integrated prototypes and precision plastic components, while Hangzhou excels in high-detail resin models and metal additive manufacturing.

The concentration of technical suppliers within these hubs allows for rapid iteration cycles—typical lead times range from 5–12 days depending on complexity. Localized supply chains reduce material costs by 20–35% compared to Western counterparts, particularly for photosensitive resins, engineering-grade thermoplastics, and specialty alloys like titanium and cobalt-chromium. Buyers benefit from agile production ecosystems where design validation, mold creation, and functional testing occur within tightly coordinated networks, supporting MOQs as low as 1 piece with scalable output up to several hundred units per month.

How to Choose Batch Prototyping Suppliers?

Selecting reliable partners requires a structured evaluation across three critical dimensions:

Technical Capability Verification

Confirm access to multi-process fabrication technologies including CNC machining, SLA/DLP 3D printing, SLM metal printing, and vacuum casting. Suppliers should demonstrate proficiency in working with diverse materials such as ABS, nylon, PC, POM, TPU, PEBA, and photosensitive resins. For functional prototypes, verify secondary processing options: electroplating, spray painting, sandblasting, mirror polishing, and Pantone color matching. Dimensional accuracy should be supported by metrology reports or first-article inspections upon request.

Production & Quality Assurance Metrics

Evaluate operational performance using verifiable KPIs:

- On-time delivery rate ≥95%

- Reorder rate >35% indicating customer retention

- Average response time ≤4 hours

- In-house quality control processes with documented inspection protocols

Prioritize suppliers with digital workflow integration—support for 3D file formats (STL, STEP, IGES), online quoting systems, and real-time progress tracking via photo/video confirmation.

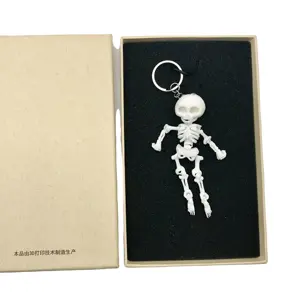

Customization and Transaction Security

Ensure clear communication channels for design modifications, labeling, packaging, and assembly requirements. Look for suppliers offering OEM/ODM support with secure handling of IP-sensitive designs. Where applicable, use transaction platforms with built-in escrow and dispute resolution mechanisms. Request physical or digital samples before full commitment, especially when tolerances, surface finish, or mechanical properties are critical.

What Are the Best Batch Prototyping Suppliers?

| Company Name | Main Processes | Materials Supported | Min. Order Quantity | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Annual Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Shenzhen GH Prototype Technology Co., Ltd | Vacuum Casting, Rapid Tooling, Silicone Molding | Resin, Plastic | 1 piece | $0.90–9.99 | 100% | ≤2h | 33% | US $20,000+ |

| Torch Mold Limited | CNC Machining, 3D Printing, Vacuum Casting | ABS, Nylon, Metal, Resin | 1 unit | $0.16–19.80 | 95% | ≤2h | 33% | US $130,000+ |

| Hangzhou Aoyi Trade Co., Ltd. | SLM Metal 3D Printing, CNC Machining, SLA | Titanium, Cobalt-Chromium, POM, Resin | 1 piece | $0.50–200 | 97% | ≤3h | 57% | US $170,000+ |

| Yongkang Qucheng Technology Co., Ltd. | SLA 3D Printing, CNC Machining, Vacuum Casting | Resin, TPU, Nylon, Titanium Alloy | 1 piece | $1–10 | 98% | ≤2h | 42% | US $230,000+ |

| Dongguan New Creation Technology Company Limited | SLA/DLP Printing, Silicone Molding, Auto Parts | Resin, Plastic, Metal Crafts | 1 set | $0.50–159 | 95% | ≤4h | 38% | US $70,000+ |

Performance Analysis

Yongkang Qucheng Technology leads in reliability with a 98% on-time delivery rate and broad customization options, including full-color printing, electroplating, and reverse modeling. Hangzhou Aoyi stands out for high-complexity applications, supporting SLM metal 3D printing and stringent dimensional precision requirements—reflected in its 57% reorder rate. Torch Mold and Shenzhen GH offer competitive pricing for entry-level prototypes, with MOQs starting at one unit and fast response times. Dongguan New Creation provides niche expertise in automotive lighting housings and resin figures, suitable for design-focused clients requiring aesthetic fidelity. All top-tier suppliers maintain sub-4-hour average response times, enabling rapid quote turnaround and iterative feedback loops.

FAQs

What is the typical lead time for batch prototyping?

Standard orders take 5–9 days, depending on process complexity. SLA/DLP printing and vacuum casting typically require 5–7 days; CNC machining and metal 3D printing may extend to 9–12 days for intricate geometries or tight tolerances.

Do suppliers accept single-piece orders?

Yes, all listed suppliers support MOQs of 1 piece or unit, making them suitable for concept validation and design testing prior to volume production.

Can I request custom finishes or branding?

Most suppliers offer post-processing services including Pantone-matched painting, silk screening, laser engraving, logo application, and packaging customization. Confirm capability alignment during initial inquiry.

Are material certifications available?

While formal ISO or RoHS certifications are not explicitly stated, many suppliers provide material traceability and compatibility data upon request. For regulated industries, demand documentation on resin composition, flame resistance, and mechanical properties.

How are intellectual property and design files protected?

Reputable suppliers implement NDA-backed workflows and restrict file access to authorized personnel. Use secure file transfer methods and confirm data deletion policies post-project completion.