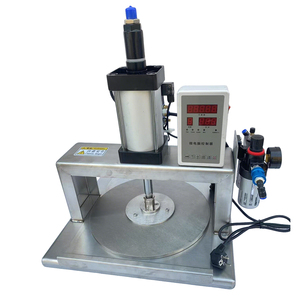

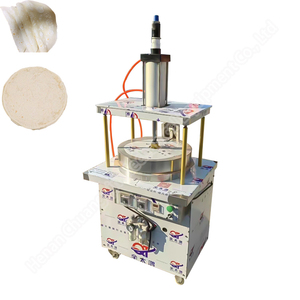

Chapati Making Machine Semi Automatic

About chapati making machine semi automatic

Where to Find Chapati Making Machine Semi Automatic Suppliers?

China remains the central hub for semi-automatic chapati making machine manufacturing, with key production clusters in Henan and surrounding regions. These industrial zones host vertically integrated supply chains specializing in grain product machinery, enabling efficient component sourcing—from heating elements to roller assemblies—and streamlined assembly processes. The concentration of food processing equipment manufacturers in cities like Zhengzhou and Luohe supports rapid prototyping and scalable production, with many suppliers operating within tightly coordinated ecosystems that include metal fabrication, electrical systems integration, and packaging.

Suppliers in this region benefit from localized access to raw materials such as stainless steel, aluminum rollers, and food-grade conveyor components, reducing material lead times by up to 40% compared to offshore alternatives. Production facilities typically integrate CNC machining, welding, and final testing lines under one roof, allowing standard order fulfillment within 20–35 days. Buyers gain flexibility in both volume and configuration, with most factories accommodating batch sizes from single units to container-scale orders while maintaining consistent quality control protocols.

How to Choose Chapati Making Machine Semi Automatic Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify machine design aligns with intended throughput (typically 600–1,500 rotis/hour for semi-automatic models) and dough compatibility (wheat, multigrain, or fermented batters). Confirm adherence to international safety standards such as CE marking for electrical systems, especially for export to EU or North American markets. Request documentation on temperature control range (usually 180–250°C), roller pressure adjustment, and power consumption (commonly 2–5 kW).

Production Capability Assessment

Evaluate supplier infrastructure based on the following criteria:

- Facility size supporting dedicated assembly and testing zones

- In-house engineering capacity for custom modifications (e.g., diameter adjustments, non-stick coating types)

- Integration of quality assurance checkpoints, including pre-shipment trial runs

Cross-reference on-time delivery rates—ideally exceeding 95%—with response times (preferably ≤3 hours) to assess operational responsiveness.

Procurement Safeguards

Utilize secure payment mechanisms such as trade assurance programs to mitigate risk. Prioritize suppliers with verifiable export histories and reorder rates above 15%, indicating customer retention. Conduct sample testing to evaluate consistency in chapati thickness (typically 1.5–3mm), browning uniformity, and cycle time stability over extended operation.

What Are the Best Chapati Making Machine Semi Automatic Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Response Time | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Kaifeng Rainbow Machinery Co., Ltd. | Grain Product Making Machines, Food Processing Lines | $410–$3,200 | 1 set | 95% | ≤2h | <15% | US $10,000+ |

| Henan Chuangqin Mechanical Equipment Co., Ltd. | Tortilla & Pita Press Machines, Customizable Units | $128–$1,900 | 2 sets | 100% | ≤2h | 15% | US $370,000+ |

| Zhengzhou Qiongdan Machinery Co., Ltd. | Semi-Automatic Roti Rollers, Pancake Presses | $550–$1,500 | 1 set | 100% | ≤3h | <15% | US $10,000+ |

| Luohe Guomipai Trading Co., Ltd. | Dough Pressing Machines, Commercial Bread Flattening | $159–$1,500 | 1 set | 95% | ≤2h | 15% | US $60,000+ |

| Zhengzhou Jawo Machinery Co., Ltd. | Roti Makers, Tortilla & Snack Equipment | $550–$1,500 | 1 set | 100% | ≤5h | 42% | US $60,000+ |

Performance Analysis

Henan Chuangqin and Zhengzhou Jawo demonstrate high operational reliability with 100% on-time delivery records and robust online transaction volumes. Zhengzhou Jawo stands out with a 42% reorder rate, suggesting strong customer satisfaction and product durability. While several suppliers offer entry-level models below $200, these are often targeted at small-scale or intermittent use; buyers seeking commercial-grade performance should focus on units priced above $500 with documented continuous-operation testing. Suppliers like Kaifeng Rainbow and Luohe Guomipai provide broad pricing tiers, facilitating options for budget-sensitive and premium applications alike.

FAQs

What is the typical MOQ for semi-automatic chapati machines?

Most suppliers list a minimum order quantity of 1 set, though some require 2 sets for lower-priced models. Volume discounts generally apply starting at 5+ units, with negotiated pricing available for container-load orders.

How long does production and shipping take?

Manufacturing lead time ranges from 15 to 30 days depending on customization level. Air freight delivers samples within 7–10 days; sea freight for bulk shipments takes 25–40 days, depending on destination port and customs procedures.

Can suppliers customize machine specifications?

Yes, many manufacturers offer modifications including roller diameter (200–400mm), voltage (220V/380V), control panel language, and footprint adjustments. Some support OEM branding and packaging design upon request.

Do these machines require special maintenance?

Routine cleaning of heating plates and rollers is essential to prevent dough buildup. Periodic inspection of electrical connections, thermostat calibration, and lubrication of moving parts ensure sustained performance. Suppliers typically provide basic maintenance guidelines and spare part lists.

Are samples available before bulk ordering?

Yes, all listed suppliers offer sample units. Sample costs are usually charged but may be partially refunded upon placement of a full order. Testing samples under real operating conditions is recommended to validate output quality and reliability.