Cnc Definition Machining

Top sponsor listing

Top sponsor listing

About cnc definition machining

Where to Find CNC Definition Machining Suppliers?

China remains the global epicenter for precision CNC machining services, with key supplier clusters concentrated in industrial hubs such as Shanghai, Shenzhen, and Xiamen. These regions host vertically integrated manufacturing ecosystems that combine advanced CNC infrastructure with access to raw materials and skilled engineering labor. The Yangtze River Delta, including Shanghai, excels in high-precision multi-axis machining, while the Pearl River Delta—centered on Shenzhen—offers rapid prototyping and low-volume customization at competitive unit costs.

Suppliers in these zones operate within mature supply networks where tooling, metrology, heat treatment, and surface finishing services are available within 50km radii. This proximity enables lead times averaging 15–25 days for custom orders and supports agile iterations for design validation. Buyers benefit from scalable production models: facilities range from mid-sized workshops handling batch runs of 50–500 pieces to larger plants capable of monthly outputs exceeding 10,000 units. Cost efficiency is further enhanced by localized sourcing of aluminum, stainless steel (e.g., SS304), and engineering plastics, reducing material procurement cycles by up to 30% compared to offshore alternatives.

How to Choose CNC Definition Machining Suppliers?

Selecting a reliable partner requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

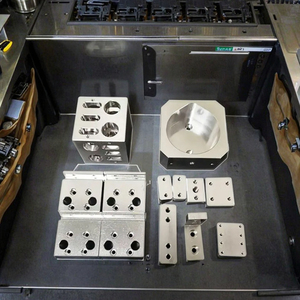

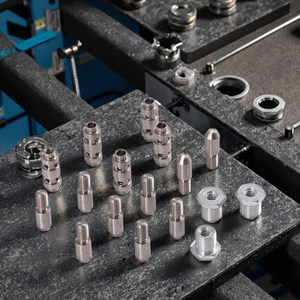

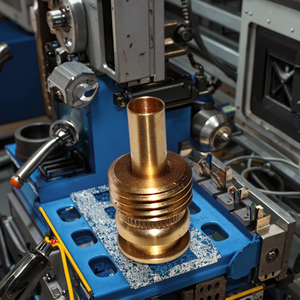

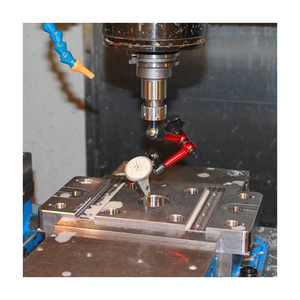

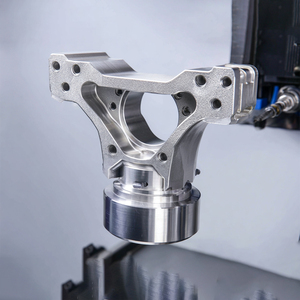

Confirm availability of multi-axis CNC centers (3-axis, 4-axis, 5-axis) and complementary processes such as turning, milling, drilling, and grinding. Suppliers should maintain documented process control plans and invest in CAD/CAM software integration for complex geometries. For critical applications, verify in-house inspection capabilities using CMMs (Coordinate Measuring Machines), optical comparators, and surface roughness testers.

Quality Management Systems

Prioritize suppliers adhering to internationally recognized standards. While ISO 9001 certification is not explicitly stated in all cases, consistent on-time delivery rates above 95% and structured quality tags suggest formalized workflows. Surface treatments like anodizing or passivation should follow ASTM or MIL-spec benchmarks. Request evidence of first-article inspection reports and process capability studies (Cp/Cpk) for high-tolerance components.

Production & Customization Flexibility

Evaluate customization depth beyond basic dimensional adjustments. Leading suppliers support full parameter modification—including material grade, color finish, logo engraving, packaging labeling, and drawing-based revisions. Minimum Order Quantities (MOQs) vary significantly:

- Entry-tier providers: MOQ of 1–3 pieces (ideal for prototypes)

- Mainstream service: 50–100 pieces per order

- Bulk manufacturers: Scalable from 500+ units with tiered pricing ($0.10–$15/unit depending on complexity)

Cross-reference listed product volumes (e.g., 298 machining service listings) with response time and reorder rate metrics to assess scalability without compromising service levels.

Transaction Reliability Indicators

Analyze performance indicators embedded in supplier profiles:

- On-time delivery rates ≥95% indicate stable scheduling and logistics management

- Response times ≤1 hour signal dedicated customer support teams

- Reorder rates above 20% reflect customer satisfaction and consistent quality

- Annual online revenue exceeding US $2 million suggests market validation and financial stability

What Are the Best CNC Definition Machining Suppliers?

| Company Name | Primary Services | Listings Count | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Estimate | MOQ Range | Unit Price Range |

|---|---|---|---|---|---|---|---|---|

| Shanghai Fangyou Precision Machinery Co., Ltd. | Machining Services (298) | 298 | 100% | ≤1h | <15% | US $9,000+ | Not specified | Not disclosed |

| Shanghai Yongzhen Machine Components Co., Ltd. | Metal Parts Machining | 5 | 95% | ≤3h | <15% | US $20,000+ | 50–100 pcs | $2–15 |

| Xiamen HYM Metal Products Co., Ltd. | Precision Milling & Anodizing | 5 | 100% | ≤3h | 47% | US $2,600,000+ | 1–3 pcs | $0.10–$1 |

| Shenzhen View Well Industry Co., Ltd. | OEM/ODM Machining | 5 | 100% | ≤3h | 20% | US $20,000+ | 1–2 pcs | $0.10–$3 |

| Zhuhai Mingjiang Machinery Technology Co., Ltd. | Stainless Steel CNC Parts | 83 | 100% | ≤13h | - | - | 5 pcs | $0.30–$5 |

Performance Analysis

Xiamen HYM stands out with the highest reported annual revenue (US $2.6M+) and a 47% reorder rate, indicating strong client retention despite minimal listing volume. Its ultra-low MOQs (1 piece) and sub-dollar pricing make it ideal for startups and R&D departments requiring fast-turnaround prototypes. Shanghai Fangyou leads in service breadth with nearly 300 machining listings and instantaneous response times (≤1h), though its low reorder rate suggests potential gaps in post-sale engagement. Zhuhai Mingjiang offers mid-tier scalability with 83 active product lines but slower communication—suitable for non-urgent bulk orders. Shenzhen View Well provides balanced flexibility across electronics, furniture, and novel stainless steel applications, with a 20% repeat order rate signaling moderate customer loyalty. Shanghai Yongzhen targets higher-value components ($2–15/unit), likely focusing on finished assemblies rather than raw part production.

FAQs

How to verify CNC machining supplier reliability?

Assess consistency in on-time delivery (target ≥95%), response speed (ideally under 3 hours), and reorder rates (above 20% preferred). Request sample parts to evaluate dimensional accuracy, surface finish quality, and adherence to technical drawings. If available, review certifications related to quality management systems or industry-specific compliance (e.g., medical, aerospace).

What is the typical lead time for CNC machined parts?

Standard lead times range from 10–25 days post-design approval. Prototypes can be delivered in 5–10 days when MOQs are below 10 units. Complex multi-operation parts involving secondary processes (heat treatment, plating, welding) may extend timelines by 7–14 days.

Can suppliers accommodate small-batch or prototype orders?

Yes. Several suppliers, including Xiamen HYM and Shenzhen View Well, accept orders as low as 1–3 pieces. These are particularly suited for product development, testing, and niche applications where volume demand is uncertain.

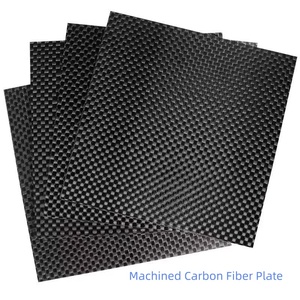

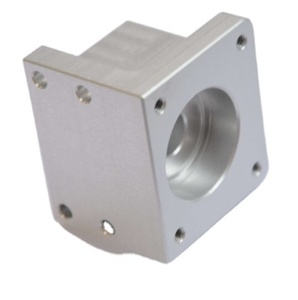

Do CNC machining suppliers offer material and finish customization?

All listed suppliers support customization across material selection (including SS304, aluminum, brass, and engineering plastics), geometric dimensions, color finishes (anodized, painted, plated), and branding elements such as laser engraving or label application. Technical drawings and 3D models are accepted for exact replication.

What are common payment and assurance practices?

While specific terms vary, established suppliers often require partial upfront payments with balance due before shipment. For new partnerships, consider secure transaction methods that include inspection rights and dispute resolution mechanisms. Retain samples from initial batches as quality benchmarks for future production runs.