Cnc Machine Tooling

1/22

1/22

1/1

1/1

0

0

1/3

1/3

1/38

1/38

0

0

1/3

1/3

1/21

1/21

1/3

1/3

1/3

1/3

1/26

1/26

0

0

1/3

1/3

1/3

1/3

CN

CN

1/9

1/9

1/21

1/21

1/10

1/10

1/3

1/3

About cnc machine tooling

Where to Find CNC Machine Tooling Suppliers?

China remains the central hub for global CNC machine tooling production, with specialized manufacturing clusters in Hunan, Jiangsu, and Anhui provinces driving efficiency and innovation. Zhuzhou, Hunan—widely recognized as China’s tungsten carbide capital—hosts over 70% of the nation’s indexable cutting tool manufacturers, leveraging vertically integrated supply chains from raw material processing to precision coating technologies. This concentration enables cost advantages of 25–40% compared to Western suppliers, particularly for carbide inserts and modular tool systems.

These industrial ecosystems support rapid prototyping and scalable production, with many facilities operating automated grinding and sintering lines capable of monthly outputs exceeding 500,000 units. Proximity to material sources such as tungsten ore and cobalt refineries reduces input volatility, while established logistics corridors facilitate export readiness. Buyers benefit from lead times averaging 15–30 days for standard tooling orders, with customization options including substrate composition, coating types (TiAlN, AlCrN), and geometric specifications available across leading suppliers.

How to Choose CNC Machine Tooling Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Quality Assurance & Compliance

Verify adherence to ISO 9001 standards as a baseline for consistent quality management. For high-precision applications, confirm process controls aligned with IATF 16949 or AS9100 where applicable. Request documentation on insert hardness testing (HRA 89–93), micrograin structure analysis, and coating adhesion performance (e.g., Rockwell C-scale tests).

Production Capacity Assessment

Evaluate key operational indicators:

- Facility size exceeding 2,000m² for sustained volume output

- In-house capabilities in powder metallurgy, CNC grinding, and PVD/CVD coating deposition

- Dedicated R&D teams focused on wear resistance and chip control optimization

Cross-reference online revenue metrics and reorder rates to assess market confidence and production stability.

Procurement Risk Mitigation

Utilize secure payment frameworks that release funds upon product verification. Prioritize suppliers with transparent response times (≤2 hours) and documented on-time delivery performance above 95%. Pre-shipment inspection protocols should include dimensional accuracy checks using coordinate measuring machines (CMM) and batch sampling per ANSI B94.19 standards.

What Are the Best CNC Machine Tooling Suppliers?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Verified Supplier |

|---|---|---|---|---|---|---|---|---|

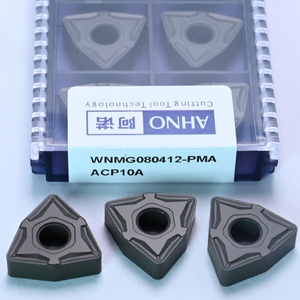

| Anhui Linghang Shengtai Cnc Technology Co., Ltd. | Anhui, CN | CNC Inserts (WNMG, CNMG, TCMT, CCMT) | Material, color, size, logo, packaging | 100% | ≤2h | US $20,000+ | <15% | Yes |

| Zhuzhou Grewin Tungsten Carbide Tools Co., Ltd. | Zhuzhou, CN | Turning Tools, Milling Cutters, Drill Bits | Not specified | 87% | ≤3h | US $70,000+ | 25% | No |

| Taizhou Hanyu Cnc Tool Co., Ltd. | Taizhou, CN | Milling Cutters, Chamfering Tools, Boring Bars | Not specified | 81% | ≤5h | US $10,000+ | 20% | No |

| Jinan Hongda Cnc Equipment Co., Ltd. | Jinan, CN | CNC Lathes, Machining Centers, Live Tool Holders | Not specified | 100% | ≤1h | US $1,100,000+ | 30% | No |

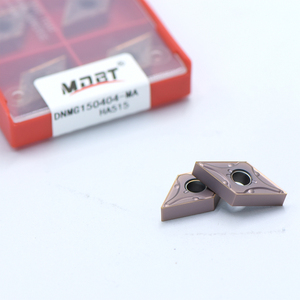

| Zhuzhou Apple Carbide Tools Co., Ltd. | Zhuzhou, CN | Carbide Inserts, Lathe Cutting Tools | Hardness, grain size, shape, coating (TiAlN), packaging | 97% | ≤4h | US $450,000+ | 28% | Yes |

Performance Analysis

Suppliers like Anhui Linghang Shengtai and Jinan Hongda demonstrate exceptional reliability with 100% on-time delivery, positioning them as preferred partners for time-sensitive procurement. Zhuzhou-based manufacturers dominate in material expertise, offering granular customization in carbide grades and coatings critical for aerospace and automotive machining. While Taizhou Hanyu shows lower delivery consistency (81%), its product range includes niche tooling such as comma-shaped blades and internal slotting cutters. High reorder rates—particularly at Jinan Hongda (30%) and Zhuzhou Apple (28%)—reflect strong customer satisfaction in both consumable tooling and capital equipment segments. Buyers seeking standardized inserts should prioritize suppliers with sub-3-hour response times and proven compliance records.

FAQs

How to verify CNC machine tooling supplier reliability?

Confirm quality certifications through official registries and request test reports for insert performance under simulated cutting conditions. Analyze transaction history, focusing on delivery consistency and dispute resolution outcomes. Conduct virtual factory audits to observe grinding, inspection, and packaging workflows.

What is the typical MOQ and pricing range?

Standard MOQ is 10 pieces for inserts, with prices ranging from $0.50 to $8.60 per unit depending on grade and geometry. Complete tool holders or CNC machines require full-set orders (MOQ: 1 set), priced between $1,500 and $18,000 based on configuration and automation level.

Can suppliers provide customized CNC tooling solutions?

Yes, select suppliers offer end-to-end customization including substrate formulation, coating type, edge preparation, and branding. Capabilities vary—Zhuzhou Apple Carbide and Anhui Linghang support modifications in size, logo, and TiAlN coating, enabling application-specific optimization for hardened steel or titanium alloys.

What are common lead times for CNC tooling orders?

Bulk orders of standard inserts typically ship within 15–20 days after confirmation. Custom-designed tools with unique geometries require 25–35 days for development and validation. Express production options may reduce timelines by 30% with expedited fees.

Do suppliers support global shipping and compliance?

Most suppliers export globally and comply with international packaging and labeling requirements. Confirm HS codes, origin documentation, and compatibility with destination-country customs regulations. FOB terms are standard; CIF arrangements are available for large machinery shipments.