Custom Prototyping Solutions

Top sponsor listing

Top sponsor listing

HK

HK

About custom prototyping solutions

Where to Find Custom Prototyping Solutions Suppliers?

China remains a dominant hub for custom prototyping solutions, with key manufacturing clusters concentrated in Shenzhen and Guangdong. These regions host vertically integrated facilities specializing in rapid prototyping, CNC machining, 3D printing, and mold development. Shenzhen’s ecosystem benefits from proximity to R&D centers and electronics supply chains, enabling agile iteration cycles for product designers and engineering firms. Guangdong’s industrial base supports high-mix, low-volume production with access to advanced materials and surface treatment capabilities.

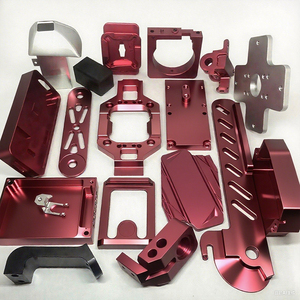

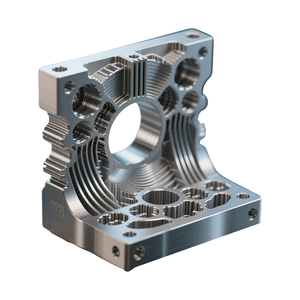

The region's suppliers leverage economies of scale through co-located material sourcing, precision fabrication, and logistics networks. This integration reduces lead times—typically 7–15 days for prototype delivery—and lowers unit costs by up to 40% compared to Western counterparts. Buyers gain flexibility in volume scaling, material selection (including ABS, PLA, titanium alloy, SS304), and finishing options such as anodic oxidation, chrome plating, and sandblasting. The presence of ODM/OEM-certified manufacturers further enables end-to-end design-to-production workflows.

How to Choose Custom Prototyping Solutions Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capabilities Verification

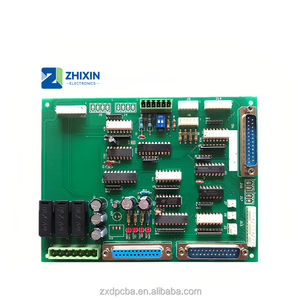

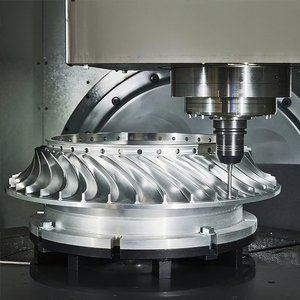

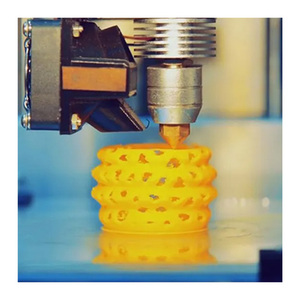

Confirm access to multi-axis CNC machining (4-axis and 5-axis), vacuum casting, SLA/SLS/SLM 3D printing, and sheet metal stamping. Suppliers should support standard file formats (STL, 3D drawings, 2D engineering prints) and offer hybrid prototyping combining additive and subtractive methods. In-house industrial design teams enhance customization agility, particularly for consumer-facing products requiring aesthetic refinement.

Quality & Compliance Assessment

While formal certifications (e.g., ISO 9001) are not explicitly stated in available data, performance indicators such as on-time delivery rates exceeding 95% serve as proxy metrics for process reliability. Prioritize suppliers maintaining ≥97% on-time delivery and sub-6-hour response times, which correlate with robust internal quality control systems. Reorder rates above 40% indicate customer satisfaction with dimensional accuracy, surface finish consistency, and revision handling.

Customization & Scalability Audit

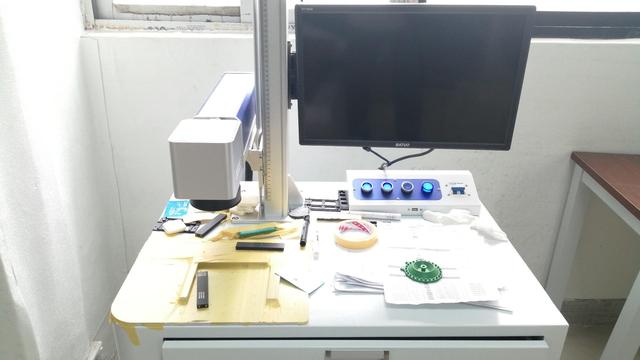

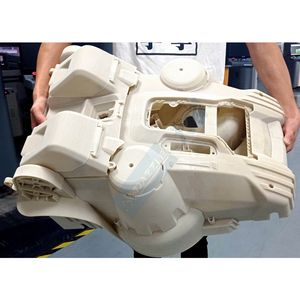

Evaluate scope of personalization: color, size, material grade, logo embossing, packaging, and labeling. Suppliers offering flexible MOQs—down to 1 piece—are ideal for early-stage prototyping. Cross-reference listed services (e.g., Rapid Tooling, Vacuum Molding, Metal Casting) with actual product listings to confirm technical depth. Video facility tours or equipment inventories help validate claims about 5-axis machining or resin-based processes.

What Are the Best Custom Prototyping Solutions Suppliers?

| Company Name | Verified Type | Main Services | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Scope |

|---|---|---|---|---|---|---|---|

| Shenzhen Strongd Model Technology Co., Ltd. | Custom Manufacturer | Machining, Moulds, Casting, Aluminum Profiles, Fabrication | 97% | ≤2h | 40% | US $50,000+ | Color, material, size, logo, packaging, graphic |

| Shenzhen Yongairui Technology Co., Ltd. | Custom Manufacturer | 3D Printing (SLA/SLS/FDM), CNC, Vacuum Casting, Sheet Metal | 97% | ≤4h | 48% | US $150,000+ | Multi-material, surface finishes, 5-axis machining, engineering drawings |

| Industrial Man Manufacturing Co., Limited | Custom Manufacturer | SLA, SLS, CNC Machining, Vacuum Casting, Rapid Tooling | 100% | ≤5h | 30% | US $20,000+ | Industrial design, hybrid molds, tapping, stl files, nylon, titanium |

| Guangdong Fohan Technology Co., Ltd. | Not Specified | 3D Printing (SLS/MJF), Machining, Polymer Fabrication | 93% | ≤9h | 40% | US $10,000+ | Limited detail; broad fabrication focus |

| Foshan Shunde Xianfeng Product Design Modeling Factory | Not Specified | CNC Machining, Sheet Metal, Stamping, Welding, PMMA Polishing | 92% | ≤6h | 40% | US $80,000+ | Functional prototypes for appliances; high-polish finishes |

Performance Analysis

Shenzhen Yongairui stands out with the highest online revenue (US $150,000+) and a 48% reorder rate, indicating strong market trust and repeat engagement. Its extensive customization matrix—including electroplating, sandblasting, and multi-axis machining—supports complex prototyping needs. Industrial Man Manufacturing achieves perfect on-time delivery (100%) despite moderate reorder volume, suggesting disciplined production planning. Shenzhen Strongd offers balanced performance with fast ≤2-hour responses and diverse service lines, making it suitable for time-sensitive projects. Guangdong Fohan and Foshan Xianfeng cater to niche applications, including large-scale polymer prints and polished acrylic components for consumer electronics or kitchen appliances.

FAQs

How to verify custom prototyping supplier reliability?

Analyze on-time delivery history, response speed, and reorder rate as operational proxies. Request evidence of in-house capabilities via facility videos or machine lists. Validate technical alignment by submitting test designs and evaluating feedback quality on manufacturability, tolerances, and material recommendations.

What is the typical prototyping lead time?

Standard prototypes are delivered within 7–12 days. Complex builds involving hybrid molding or multi-material 3D printing may require 14–20 days. Rush services (3–5 days) are often available at premium pricing, subject to equipment availability.

Do suppliers support full product development cycles?

Yes, leading providers offer integrated design services (ODM/OEM), enabling clients to transition from concept sketches to functional prototypes. Some include reverse engineering via 3D scanning and STL file generation, supporting iterative refinement before mass production.

What are common MOQs and pricing structures?

Most suppliers list MOQs of 1 piece, accommodating single-unit sampling. Pricing varies by technology: FDM/SLA starts at $0.50/unit, while CNC-machined metal parts range from $1–$100 depending on complexity. Transparent tiered pricing models reflect scalability for pilot batches (10–100 units).

How to manage international shipping and compliance?

Suppliers typically export globally using standard Incoterms (FOB, CIF). Ensure compliance with destination regulations for electronic components or treated metals. Use third-party inspection services for batch validation if scaling beyond prototype phase. Digital documentation (drawings, test reports) should be provided in English to streamline communication.