Fabric Button Maker

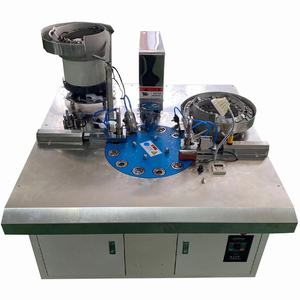

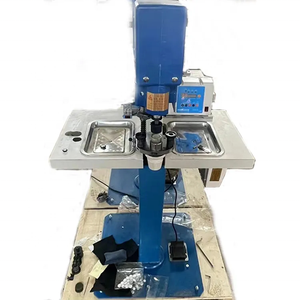

About fabric button maker

Where to Find Fabric Button Maker Suppliers?

China remains the global epicenter for fabric button maker manufacturing, with key industrial clusters concentrated in Shandong, Guangdong, and Henan provinces. Shandong’s Qingdao region specializes in heavy-duty upholstery and semi-automatic machinery, leveraging localized steel and mechanical component supply chains to reduce production costs by 15–20%. Guangdong’s Shenzhen and Foshan hubs focus on precision metalworking and automated systems, benefiting from mature electronics integration and CNC processing networks. Henan’s Zhengzhou cluster emphasizes scalable production of mid-range pressing equipment, supporting high-volume output with streamlined logistics.

These regions offer vertically integrated ecosystems where casting, machining, heat treatment, and final assembly occur within compact geographic zones. This integration enables lead times averaging 20–35 days for standard orders and supports flexible customization in tooling, pressure settings, and material compatibility. Buyers benefit from consolidated sourcing—where dies, molds, and spare parts are readily available—and access to suppliers with export experience across North America, Europe, and Southeast Asia.

How to Choose Fabric Button Maker Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical & Production Capabilities

Assess whether suppliers maintain in-house engineering teams capable of die design and machine calibration. Prioritize manufacturers with dedicated R&D functions and documented experience in modifying press force (typically 5–20 tons) for varying fabric densities. Confirm availability of core processing capabilities: CNC machining, hydraulic system integration, and mold fabrication. Facilities exceeding 3,000m² generally support batch production and inventory buffering for export orders.

Quality Assurance Protocols

While formal ISO 9001 certification is not universally declared in available data, consistent on-time delivery rates above 95% and response times under 12 hours indicate operational discipline. Look for suppliers with verifiable quality control checkpoints—such as pre-shipment testing of pressing accuracy and cycle durability. For automated models, demand validation of motor longevity and sensor reliability under continuous operation.

Customization and Compliance

Leading suppliers offer configurable options including size-specific dies (ranging from 10mm to 40mm), material compatibility adjustments (fabric, leather, synthetic textiles), and branding via logo imprinting or color coating. Verify compliance with destination-market electrical standards (e.g., CE for EU, UL for U.S.) for powered units. Request technical drawings and sample outputs before committing to bulk orders.

Transaction Security & Logistics

Utilize secure payment mechanisms such as escrow services, particularly when engaging newer suppliers without long-term trade histories. Analyze reorder rates—values above 20% suggest customer satisfaction and product reliability. Most suppliers support FOB shipping terms; confirm packaging standards (wooden crates for automated units) and inland freight coordination from factory to port.

What Are the Best Fabric Button Maker Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Notable Offerings |

|---|---|---|---|---|---|---|---|

| Qingdao Liaode Machinery Co., Ltd. | Shandong, CN | Cap Making Machines (45), Interlinings (7) | US $10,000+ | 100% | ≤11h | 15% | Manual to automatic fabric button machines ($180–$4,600); cap-focused tooling integration |

| Foshan Jusfer Metal Products Co., Ltd. | Guangdong, CN | Belt Buckles (93), Buttons (62) | US $20,000+ | 84% | ≤13h | 25% | Low-cost hand-press units ($35); buckle and eyelet co-processing machines |

| Shenzhen Shengmingfa Technology Co., Ltd. | Guangdong, CN | Sewing Machines (2,028), Injection Molding (708) | US $30,000+ | 100% | ≤5h | 20% | Used industrial-grade eyelet and fabric cover machines; Brother/JUKI reconditioned units |

| Zhengzhou Pasen Machinery Co., Ltd. | Henan, CN | Customizable pressing equipment | US $250,000+ | 100% | ≤4h | 16% | Semi-auto upholstery machines ($1,100+); full customization (color, size, logo, packaging) |

| Shenzhen Richest Pack Limited | Guangdong, CN | Automatic snap button machines (5) | US $190,000+ | 95% | ≤4h | 19% | Full-auto plastic/metal snap machines ($1,700–$2,400); mold and die design support |

Performance Analysis

Qingdao Liaode and Zhengzhou Pasen demonstrate strong operational reliability with 100% on-time delivery and extensive customization capabilities, making them suitable for stable, medium-to-high volume procurement. Foshan Jusfer stands out with a 25% reorder rate, indicating strong buyer retention despite slightly lower delivery performance, likely due to competitive pricing in entry-level manual presses. Shenzhen-based Shengmingfa excels in responsiveness (≤5h) and offers cost-effective used machinery, ideal for startups or small workshops. Shenzhen Richest Pack provides advanced automation with in-house mold engineering, catering to technical buyers requiring precision consistency.

FAQs

What is the typical MOQ for fabric button makers?

Most suppliers set a minimum order quantity of 1–2 sets, regardless of automation level. Manual and semi-automatic models often allow single-unit purchases, while fully automatic systems may require two-set minimums for international shipments.

How long does production and shipping take?

Lead times average 20–30 days for manufacturing and inspection. Air freight delivers samples within 7–10 days; sea freight for full containers takes 25–35 days depending on destination port. Expedited builds (12–18 days) are possible with confirmed customization parameters.

Can I request custom dies or molds?

Yes, multiple suppliers—including Zhengzhou Pasen and Shenzhen Richest Pack—offer mold and die customization based on provided drawings or physical samples. Turnaround for new tooling is typically 7–14 days, with additional costs ranging from $150–$600 depending on complexity.

Do suppliers provide machine testing before shipment?

Reputable manufacturers conduct functional tests on hydraulic pressure, alignment accuracy, and cycle duration. Request video demonstrations or third-party inspection reports (e.g., SGS) for automated units. Some suppliers include trial-produced buttons with each shipment for quality verification.

Are spare parts and technical support available?

Leading suppliers stock common wear components such as dies, pins, and sealing rings. Technical guidance is typically offered via email or video call, with some providers supplying user manuals in English and basic troubleshooting checklists. Long-term service agreements are uncommon but can be negotiated for large installations.