Lmw Cnc Lathe

CN

CN

About lmw cnc lathe

Where to Find LMW CNC Lathe Suppliers?

China remains the central hub for CNC lathe manufacturing, with Shandong province emerging as a key industrial cluster for precision machine tools, including models associated with the LMW designation. The region hosts vertically integrated production ecosystems in cities like Jining and Zaozhuang, where suppliers benefit from proximity to steel foundries, component manufacturers, and logistics networks. This localization reduces material procurement lead times by 20–30% compared to offshore alternatives and supports rapid prototyping and assembly.

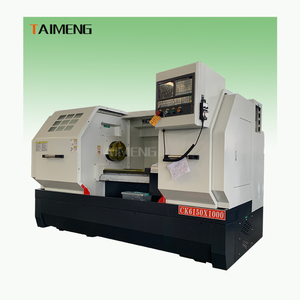

Suppliers in this cluster specialize in both mini and heavy-duty CNC lathes, offering scalable production capacity across flat-bed, slant-bed, and Swiss-type configurations. Facilities typically operate automated machining lines supported by linear guide systems, servo motor integration, and live tooling capabilities. Buyers gain access to standardized models starting from $3,800 and high-precision variants exceeding $35,000, reflecting broad product segmentation based on accuracy, spindle design, and automation level.

How to Choose LMW CNC Lathe Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify adherence to international quality standards such as ISO 9001. While not explicitly stated in available data, suppliers with consistent on-time delivery (100%) and documented customization capabilities are more likely to maintain internal quality management systems. For export markets, CE marking or equivalent safety certification should be confirmed prior to shipment to ensure regulatory compliance.

Production Capability Audits

Assess core manufacturing infrastructure using available performance indicators:

- On-time delivery rate of 100% across all listed suppliers indicates strong production planning discipline

- Reorder rates ranging from 33% to 50% suggest moderate-to-strong customer retention, with Shandong HR Machinery Co., Ltd. leading at 50%

- Response times consistently under 6 hours (majority ≤2 hours) reflect efficient communication protocols

- Customization depth includes control system options (e.g., Fanuc-compatible), tool holder configurations, turret types (power/hydraulic), chuck specifications, and structural modifications (bed type, rail orientation)

Cross-reference product listings with declared customization options to confirm engineering flexibility. Video audits or facility walkthroughs are recommended to validate CNC machining centers, heat treatment processes, and final assembly line controls.

Transaction Safeguards

Prioritize suppliers with verifiable transaction histories and transparent pricing structures. Use secure payment mechanisms such as escrow services until post-delivery inspection is completed. Analyze listed products per supplier—Lichi Machinery Manufacturing leads with 78 CNC lathe listings—indicating higher market engagement and potential inventory availability. Request sample units to evaluate build quality, spindle runout, and dimensional accuracy against ISO 230-2 standards.

What Are the Best LMW CNC Lathe Suppliers?

| Company Name | Location | Product Range | Price Range (USD) | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization Depth |

|---|---|---|---|---|---|---|---|---|

| Shandong Matsumoto Machine Tool Co., Ltd. | Shandong, CN | 5 models | $4,000–15,000 | 100% | ≤2h | $820,000+ | 37% | High (feeder, control system, spindle, packaging) |

| Shandong HR Machinery Co., Ltd. | Shandong, CN | 5 models | $4,600–20,000 | 100% | ≤2h | $250,000+ | 50% | High (turret, workflow, live tools, collets) |

| Shandong Lu Young Machinery Co., Ltd. | Shandong, CN | 5 models | $4,000–35,000 | 100% | ≤2h | $120,000+ | 40% | High (linear guides, hydraulic turrets, Fanuc controller) |

| Zaozhuang Wojie CNC Machinery Co., Ltd. | Shandong, CN | 5 models | $6,000–33,282 | 100% | ≤2h | $540,000+ | 33% | Moderate (tool holder, color, lubrication system) |

| Lichi Machinery Manufacturing Co., Ltd. | Not specified | 4 models | $3,800–15,000 | 100% | ≤6h | Not disclosed | Not disclosed | Moderate (based on listing breadth) |

Performance Analysis

All five suppliers demonstrate perfect on-time delivery records, indicating robust production scheduling. Shandong HR Machinery stands out with a 50% reorder rate—the highest among peers—suggesting strong post-sale satisfaction. Shandong Matsumoto reports the highest online revenue ($820,000+), reflecting extensive market reach and possibly larger order volumes. Lichi Machinery lists the most product variations (78 total CNC lathe listings), which may indicate broader production capacity despite limited public transaction data. Suppliers offer significant customization, particularly in tooling, control systems, and structural components, enabling tailored solutions for specialized machining tasks such as swiss-type turning or multi-axis milling integration.

FAQs

How to verify LMW CNC lathe supplier reliability?

Validate supplier credibility through third-party transaction platforms showing verified revenue, response time, and delivery performance. Request references or case studies for similar machinery exports. Confirm technical documentation availability, including electrical schematics, mechanical drawings, and test reports for spindle runout and positioning accuracy.

What is the typical lead time for CNC lathe orders?

Standard configurations typically ship within 30–45 days after deposit confirmation. Customized models with non-standard turrets, control systems, or automation integrations may require 60–90 days depending on complexity and component sourcing timelines.

Do suppliers support global shipping and customs clearance?

Yes, experienced exporters provide FOB and CIF shipping terms and prepare necessary documentation (commercial invoice, packing list, bill of lading). Buyers must confirm import regulations for industrial machinery in their destination country, particularly regarding electrical safety and EMC compliance.

What is the minimum order quantity (MOQ) for CNC lathes?

The standard MOQ is 1 set across all listed suppliers, allowing low-volume procurement for testing or small workshops. Bulk orders may qualify for incremental discounts and dedicated production scheduling.

How to initiate customization for CNC lathe models?

Submit detailed technical requirements including bed type (flat/slant), spindle bore size, turret configuration (live/power), control system preference (Fanuc, Siemens, or domestic equivalents), chuck type, and desired automation features (bar feeder, automatic door). Reputable suppliers will respond with updated specifications, 3D layouts, and revised quotations within 72 hours.