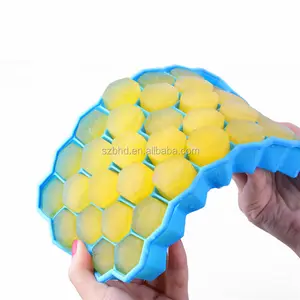

Perfect Ice Cube Maker

About perfect ice cube maker

Where to Find Perfect Ice Cube Maker Suppliers?

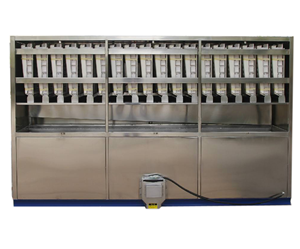

China remains the global hub for ice cube maker production, with concentrated manufacturing expertise in Guangdong and Jiangsu provinces. Dongguan and Shenzhen serve as primary centers for silicone-based ice tray fabrication, leveraging advanced rubber molding technologies and proximity to polymer supply chains. Suzhou and Guangzhou specialize in commercial-grade electric ice machines, integrating refrigeration engineering with stainless steel fabrication capabilities. These regional clusters enable vertically integrated production—from raw material processing to final assembly—reducing component lead times by 20–35% compared to decentralized models.

The ecosystem supports both high-volume disposable molders and engineered appliance manufacturers. Silicone product suppliers typically operate injection molding lines capable of 50,000+ units per month, while industrial ice machine producers maintain dedicated R&D teams for thermal system optimization. Buyers benefit from localized access to packaging, labeling, and logistics services within 30km radii, enabling faster turnaround on bulk orders. Average production cycles range from 15–25 days for molded trays and 30–45 days for electromechanical units, depending on customization depth.

How to Choose Perfect Ice Cube Maker Suppliers?

Evaluate potential partners using these critical criteria:

Material & Compliance Standards

Confirm use of food-grade silicone (FDA 21 CFR 177.2600) or BPA-free plastics for consumer products. For commercial ice machines, verify CE, RoHS, and NSF certifications where applicable, particularly for electrical safety and hygiene compliance in foodservice environments. Request test reports for material durability, including freeze-thaw cycle resistance (minimum 1,000 cycles) and deformation under -40°C conditions.

Production Capacity Verification

Assess operational scale through key indicators:

- Minimum factory area exceeding 2,000m² for consistent output

- In-house mold design and CNC tooling capabilities

- Monthly production capacity above 100,000 units for trays or 500+ units for machines

Cross-reference online revenue metrics and reorder rates (target >25%) to validate order fulfillment consistency and customer retention.

Customization & Transaction Security

Prioritize suppliers offering private labeling, color matching (Pantone standards), and cavity configuration adjustments. Ensure secure transaction protocols via verified payment systems. Demand sample validation before mass production—particularly for dimensional accuracy in "perfect cube" specifications (±0.5mm tolerance). Confirm packaging integrity testing for drop and temperature shock resilience during transit.

What Are the Best Perfect Ice Cube Maker Suppliers?

| Company Name | Location | Main Products | MOQ Range | Avg. Unit Price | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Dongguan Qiaotou Kingsage Silicone Rubber Factory | Guangdong, CN | Silicone Ice Trays | 100–500 pcs | $0.60–$0.95 | 100% | ≤21h | - | US $300+ |

| Shenzhen Benhaida Rubber And Plastic Products Co., Ltd. | Guangdong, CN | Molded Silicone Trays | 50–100 units | $1.11–$21.00 | 97% | ≤3h | 22% | US $230,000+ |

| Suzhou Iceman Refrigeration Equipment Co., Ltd. | Jiangsu, CN | Electric Ice Machines | 1 unit | $699–$2,299 | 50% | ≤3h | 27% | US $40,000+ |

| Shenzhen Jiangqixing Industrial Co., Ltd. | Guangdong, CN | Silicone Trays & Custom Molds | 1–100 sets | $0.70–$3.31 | 94% | ≤2h | 33% | US $210,000+ |

| Guangzhou Huli Catering Equipment Co., Ltd. | Guangdong, CN | Commercial Ice Makers | 1–2 units | $229–$2,573 | 100% | ≤2h | 33% | US $8,000+ |

Performance Analysis

Dongguan Qiaotou Kingsage offers the lowest entry MOQs and competitive pricing for basic silicone trays, though limited response speed may affect communication efficiency. Shenzhen Benhaida and Jiangqixing demonstrate strong customization capabilities with sub-3-hour response times and repeat order performance above 22%, indicating reliable service delivery. Among equipment manufacturers, Guangzhou Huli achieves 100% on-time shipment rates despite complex logistics, making it a preferred partner for urgent commercial deployments. Suzhou Iceman, while technically specialized, shows lower delivery reliability (50%), suggesting potential bottlenecks in fulfillment processes. Buyers seeking precision-formed "perfect cube" trays should prioritize suppliers with in-house mold engineering and color control systems, whereas large-scale foodservice operators must validate refrigeration performance data and energy consumption ratings prior to procurement.

FAQs

How to verify ice cube maker material quality?

Request FDA or LFGB compliance documentation for silicone components. Conduct第三方 (third-party) lab tests for extractables, tensile strength (≥4 MPa), and elongation at break (>300%). For plastic trays, confirm BPA-free status via GC-MS analysis.

What is the typical sampling timeline?

Standard silicone tray samples take 7–10 days to produce; custom molds require 15–20 days. Electric ice machine samples need 25–35 days due to regulatory testing. Air shipping adds 5–7 days globally.

Can suppliers accommodate private labeling?

Yes, most manufacturers support logo printing, custom packaging, and Pantone color matching. Minimum order thresholds vary: 1,000 units for full branding, 500 units for label-only customization.

Do ice cube makers require export certification?

Electromechanical units require CE, ETL, or CCC marks depending on destination. Passive trays only need material compliance. Confirm country-specific import requirements for voltage, plug type, and safety standards.

How to negotiate better terms with suppliers?

Leverage order volume (e.g., container-load quantities) for price reductions. Request bundled services like free packaging design or consolidated shipping. Use reorder rate and delivery performance data as negotiation leverage for improved payment terms.