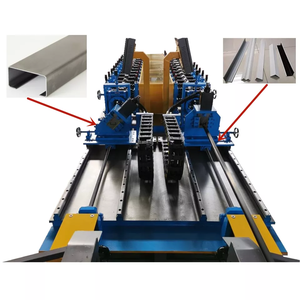

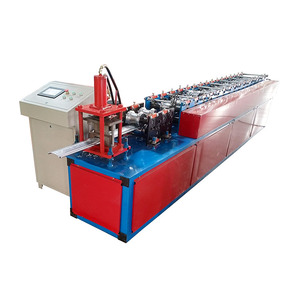

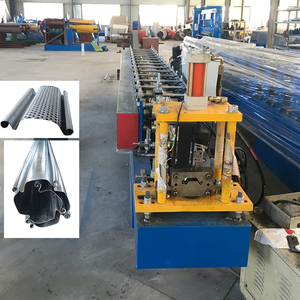

Rolling Shutter Profile Making Machine

CN

CN

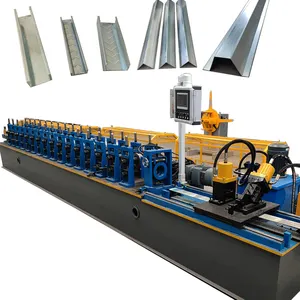

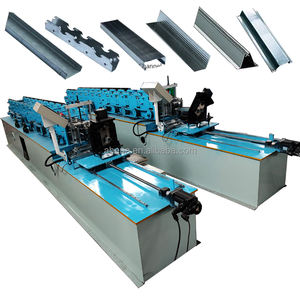

About rolling shutter profile making machine

Where to Find Rolling Shutter Profile Making Machine Suppliers?

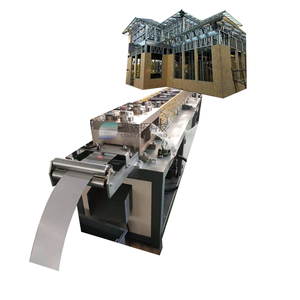

China remains the global epicenter for rolling shutter profile making machine production, with key manufacturing clusters in Hebei, Jiangsu, and Guangdong provinces. These regions host vertically integrated facilities specializing in cold roll forming technology, enabling efficient production of precision shutter profiles from steel, aluminum, and composite materials. Cangzhou in Hebei Province alone accounts for over 40% of China’s door profile machinery output, supported by a dense network of metal processing suppliers and logistics infrastructure that reduces component lead times by up to 25%.

The industrial ecosystems in these hubs offer buyers access to mature supply chains—from coil feeding systems to PLC-controlled cutting units—allowing for rapid prototyping and scalable production. Facilities typically operate automated assembly lines capable of producing 8–15 sets of machines monthly per production line. This concentration enables shorter delivery cycles (average 30–45 days for standard configurations) and cost efficiencies, with localized sourcing reducing overall manufacturing expenses by 18–22% compared to non-specialized regions.

How to Choose Rolling Shutter Profile Making Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance

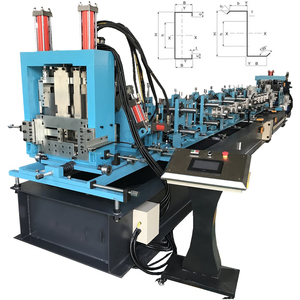

Confirm adherence to international quality standards such as ISO 9001 for quality management systems. For export to regulated markets (EU, North America), verify CE marking compliance and request documentation on electrical safety (IEC standards) and mechanical design (EN 10365). Ensure machines integrate core components like Schneider or Siemens PLCs, ABB inverters, and hardened tool steels (HRC 58–62) for roll dies.

Production Capability Audits

Assess supplier infrastructure using these benchmarks:

- Minimum factory area exceeding 3,000m² to support full production lines

- In-house engineering teams handling custom roll design and automation integration

- On-site CNC machining and welding capabilities to maintain dimensional accuracy

Cross-reference declared response times and on-time delivery rates—target suppliers with ≤7-hour average response and ≥95% on-time fulfillment based on verifiable transaction history.

Transaction Safeguards

Utilize secure payment mechanisms such as third-party escrow or Trade Assurance programs. Prioritize suppliers offering sample testing prior to bulk orders. Request test reports including profile tolerance verification (±0.2mm), line speed consistency (10–25m/min), and continuous operation endurance (≥72 hours under load).

What Are the Best Rolling Shutter Profile Making Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | MOQ Range | Price Range (USD) | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Foshan Pusheng Hardware Machinery & Mold Co., Ltd. | Guangdong, CN | Steel Frame & Purlin Machines, Tile Making Machinery | US $10,000+ | 100.0% | ≤7h | 1 set | $10,000–12,500 | - |

| Suzhou Start Technology Co., Ltd. | Jiangsu, CN | Window and Door Making Machinery, Pipe Making Machinery | Not disclosed | 100.0% | ≤12h | 1–2 sets | $7,000–26,000 | - |

| Cangzhou Guangchi Machinery Co., Ltd. | Hebei, CN | Steel Frame & Purlin Machines, Metal Product Processing Line | US $5,000+ | 100.0% | ≤2h | 1 set | $5,200–9,000 | - |

| HENAN SUPERB MACHINERY CO., LTD. | Henan, CN | Customization: color, material, size, logo, packaging | US $210,000+ | 95.0% | ≤3h | 1 set | $1,900–7,500 | 15% |

| Botou Shitong Cold Roll Forming Machinery Manufacturing Co., Ltd. | Hebei, CN | Tile Making Machinery, Steel Frame & Purlin Machines | US $20,000+ | 100.0% | ≤3h | 1 set | $6,800–10,000 | - |

Performance Analysis

Cangzhou Guangchi stands out for competitive pricing ($5,200–5,400 for automatic models) and rapid ≤2-hour response time, ideal for time-sensitive procurement. HENAN SUPERB offers the lowest entry-level pricing ($1,900) and extensive customization options but has a lower on-time delivery rate (95%) compared to peers. Foshan Pusheng and Botou Shitong provide mid-to-high-end solutions with consistent 100% on-time performance, suitable for buyers prioritizing reliability over cost minimization. Suzhou Start caters to diversified needs with a broad product range, including high-end models priced up to $26,000 for specialized applications. Buyers seeking OEM/ODM flexibility should engage suppliers explicitly listing customization capabilities in materials, labeling, and graphical design.

FAQs

How to verify rolling shutter profile making machine supplier reliability?

Validate certifications through official registries and request audit trails covering raw material sourcing, weld inspections, and final functional testing. Analyze customer feedback focusing on post-installation support, spare parts availability, and control system usability.

What is the typical lead time for standard machines?

Standard configurations are typically delivered within 30–45 days after order confirmation. Customized systems may require 50–65 days depending on complexity and component availability.

Do suppliers support global shipping and installation?

Yes, most established manufacturers offer CIF/FOB terms and coordinate sea freight logistics. Some provide optional on-site commissioning and training services—confirm availability and associated costs during negotiation.

Are samples available before bulk ordering?

While full-machine samples are uncommon due to size and cost, suppliers often provide fabricated shutter profiles produced on the same line. These can be used to assess material feed stability, cut precision, and surface finish quality.

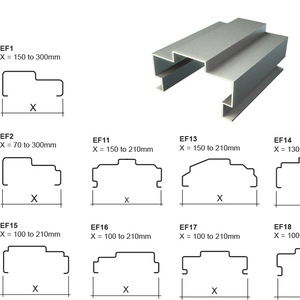

What customization options are commonly offered?

Suppliers frequently support adjustments in roll station count (12–24 stations), motor power (3–7.5kW), voltage (380V/50Hz or customized), and control interfaces (Siemens/HMI). Material compatibility can be tailored for galvanized steel (0.6–1.5mm), aluminum, or color-coated coils. Logo printing and packaging branding are also widely available.