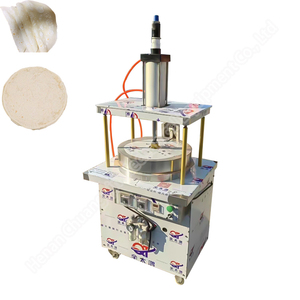

Semi Automatic Chapati Rolling Machine

1/3

1/3

1/21

1/21

1/15

1/15

About semi automatic chapati rolling machine

Where to Find Semi Automatic Chapati Rolling Machine Suppliers?

China remains the primary global manufacturing hub for semi automatic chapati rolling machines, with concentrated supplier clusters in Henan and Guangdong provinces. Henan's machinery ecosystem is particularly robust, hosting specialized manufacturers of grain processing equipment that benefit from integrated supply chains for motors, heating elements, and stainless steel components. These regional networks enable cost efficiencies of 20–30% compared to equivalent production outside Asia, driven by localized sourcing and mature food processing technology expertise.

Suppliers in this sector typically operate within vertically aligned industrial zones where design, fabrication, and assembly occur under one roof. This integration supports rapid prototyping and scalable output, with lead times averaging 15–30 days for standard configurations. The presence of established logistics corridors further enhances export readiness, allowing direct container loading for LCL or FCL shipments. Buyers gain access to a diverse product range—from compact tabletop models to industrial-scale systems—enabling alignment with commercial kitchen throughput requirements.

How to Choose Semi Automatic Chapati Rolling Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify machine compatibility with regional voltage standards (e.g., 220V/50Hz or 110V/60Hz) and material specifications such as food-grade stainless steel (SS304 preferred). While formal certifications like CE or ISO 9001 are not universally declared in available data, request documentation for electrical safety compliance and thermal control accuracy. Confirm adjustable rolling thickness (typically 2–30mm) and hourly output capacity (ranging from 800–2,500 pieces/hour depending on model).

Production and Customization Capability

Assess supplier infrastructure through verifiable indicators:

- Minimum factory area supporting dedicated assembly lines for food processing equipment

- In-house engineering capacity for custom modifications (e.g., non-stick coating, motor power upgrades, footprint adjustments)

- Use of precision machining for roller alignment to ensure uniform dough compression

Cross-reference listed product ranges with response times and reorder rates where available to gauge operational stability.

Procurement Safeguards

Prioritize suppliers offering third-party inspection options prior to shipment. Utilize secure payment mechanisms that link disbursement to quality verification at origin. Request sample units to evaluate build quality, noise levels, and ease of cleaning before placing bulk orders. Analyze pricing consistency across multiple listings to identify standardized versus customized production models.

What Are the Best Semi Automatic Chapati Rolling Machine Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | Response Time | On-Time Delivery | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| CQ MECHANICAL TECHNOLOGY INC | Chapati, Tortilla, Pneumatic Press Systems | $600 – $5,882 | 1 piece/set | ≤2h | Not specified | Not specified | Not specified |

| Henan Deshine Machinery Co., Ltd. | Electric Dough Press, Roti Maker, Snack Equipment | $400 – $560 | 1 set | ≤3h | 100% | <15% | US $80,000+ |

| MAOCHAN MACHINERY INC | Dough Sheeters, Laminate Rollers, Bread Lines | $300 – $6,313 | 1 piece/set | ≤5h | Not specified | Not specified | Not specified |

Performance Analysis

Henan Deshine Machinery stands out with verified on-time delivery performance (100%) and transparent online revenue metrics, indicating consistent export operations. Its competitive pricing ($400–$560) and sub-3-hour response time reflect operational efficiency suited for mid-volume buyers. CQ MECHANICAL TECHNOLOGY INC offers broader product variation, including high-capacity systems exceeding $5,000, suggesting capability for large-scale automation projects. MAOCHAN MACHINERY INC presents entry-level options starting at $300 but lacks delivery and reorder metrics, increasing due diligence requirements. Suppliers listing “Main products” in grain and snack processing machinery demonstrate domain specialization critical for long-term support and spare parts availability.

FAQs

How to verify semi automatic chapati rolling machine supplier reliability?

Evaluate response consistency, product specification clarity, and inclusion of technical parameters (voltage, power rating, dimensions). Request references or third-party audit reports if planning high-value procurement. Confirm post-sale service capabilities, including availability of replacement rollers and heating plates.

What is the typical minimum order quantity (MOQ)?

Most suppliers list an MOQ of 1 set or piece, facilitating low-risk sampling. However, unit prices may decrease significantly at 5+ units, especially for fully assembled systems with conveyor integration.

Are customization options available?

Yes, common modifications include variable speed controls, non-stick roller coatings, and compact designs for small kitchens. Confirm whether CAD drawings or prototypes can be provided prior to production commencement.

What are the average lead times?

Standard orders typically ship within 15–20 days after confirmation. Custom builds may require 25–35 days depending on mechanical adjustments and component sourcing.

Do suppliers provide machine testing documentation?

While not standard, reputable manufacturers can provide video demonstrations or test run logs upon request. Insist on pre-shipment inspection clauses in purchase agreements to validate functionality before release of final payment.