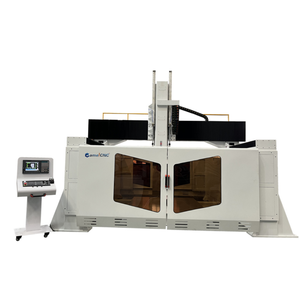

Siemens 5 Axis Cnc Controller

CN

CN

CN

CN

CN

CN

About siemens 5 axis cnc controller

Where to Find Siemens 5-Axis CNC Controller Suppliers?

China remains the central hub for advanced CNC machinery production, with key manufacturing clusters in Shandong and Jiangsu provinces driving innovation and cost efficiency in multi-axis machining systems. Shandong, particularly Jinan and Qingdao, hosts a dense network of specialized CNC equipment manufacturers that integrate Siemens control technology into high-precision milling and routing platforms. These regions benefit from established industrial ecosystems—backed by local steel, electronics, and automation component suppliers—enabling vertical integration that reduces lead times by up to 25% compared to decentralized production models.

The cluster advantage extends to rapid prototyping and customization capabilities, where suppliers maintain in-house engineering teams and CNC assembly lines within compact geographic zones. This proximity facilitates real-time quality adjustments and faster response to technical modifications. Buyers can expect standard delivery windows of 30–45 days for configured 5-axis systems with Siemens controllers, supported by localized testing facilities. Cost efficiencies range from 20–35% over European or North American equivalents due to lower labor overheads and streamlined supply chains.

How to Choose Siemens 5-Axis CNC Controller Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Integration & Compliance

Confirm that the supplier demonstrates proven integration of Siemens CNC control systems (e.g., Sinumerik series) with mechanical motion components. Request documentation verifying compatibility between controller firmware, servo drives, and machine kinematics. For international compliance, CE marking is essential for EU market access, while UL/CSA alignment may be required for North American deployments. Validate electrical safety standards and EMI shielding practices.

Production Infrastructure Assessment

Evaluate core manufacturing competencies through objective benchmarks:

- Facility size exceeding 3,000m² indicating capacity for full-scale production

- In-house R&D departments capable of custom programming and axis calibration

- Integrated machining centers for precision fabrication of gantry frames, ball screws, and rotary tables

Cross-reference on-time delivery performance (target ≥98%) with response time metrics (ideally ≤3 hours) as indicators of operational discipline.

Transaction Security & Quality Assurance

Prioritize suppliers offering third-party inspection options prior to shipment. Utilize secure payment mechanisms such as escrow services to mitigate risk during initial procurement phases. Demand sample testing protocols—including dry-run demonstrations and tool path accuracy verification under load conditions. Analyze reorder rates as a proxy for customer satisfaction; values above 30% indicate consistent product reliability and post-sales support effectiveness.

What Are the Leading Siemens 5-Axis CNC Controller Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Jinan Hongda Cnc Equipment Co., Ltd. | Jinan, Shandong | CNC Lathe, Machining Centre, EDM, Wood Router | US $990,000+ | 100% | ≤1h | 30% | $4,700–20,000 | Limited |

| Shandong Shanshu Machinery Co., Ltd. | Shandong | Wood Routers, Mortising, Boring Machines | US $120,000+ | 100% | ≤3h | 33% | $18,000–70,000 | Standard configurations |

| Jinan Spower Machinery Technology Co., Ltd. | Jinan, Shandong | 5-Axis CNC Routers, Milling Systems | US $230,000+ | 100% | ≤1h | 58% | $12,800–58,999 | Extensive (spindle type, ATC, safety systems, dimensions) |

| Shandong Camel Cnc Machinery Co., Ltd. | Shandong | 5-Axis CNC Routers, Engraving Systems | US $20,000+ | 100% | ≤3h | <15% | $30,000–60,000 | Basic (color, size, packaging) |

| Ningbo Kaibo CNC Machinery Co., Ltd. | Ningbo, Zhejiang | CNC Milling Machines, Machining Centres | Not disclosed | 100% | ≤16h | Not disclosed | $13,000–42,000 | Limited |

Performance Analysis

Jinan Spower Machinery stands out with a 58% reorder rate—the highest among listed suppliers—indicating strong customer retention driven by extensive customization capabilities and responsive service. The company offers scalable solutions ranging from entry-level 5-axis routers to heavy-duty industrial mills, all featuring Siemens-compatible controls. In contrast, Shandong Camel Cnc Machinery commands premium pricing but reports a low reorder rate (<15%), suggesting potential gaps in after-sales support or long-term reliability. Ningbo Kaibo presents competitively priced options but exhibits slower response times (≤16h), which may delay project timelines for time-sensitive buyers. Suppliers based in Shandong demonstrate superior responsiveness, with four of five achieving sub-3-hour average reply speeds.

FAQs

How to verify Siemens 5-axis CNC controller integration quality?

Request system diagnostics logs and proof of successful test runs using G-code programs with complex interpolation paths. Verify firmware version compatibility with Siemens official releases. On-site or video audits of final assembly and calibration processes provide critical validation of integration integrity.

What is the typical minimum order quantity (MOQ)?

All listed suppliers specify an MOQ of 1 set, enabling low-volume procurement for pilot installations or small workshops. Bulk discounts are typically available starting at 3–5 units, depending on machine complexity and customization level.

Are customization options widely available?

Yes, especially among mid-tier to high-end suppliers like Jinan Spower, which supports modifications including spindle power (5–15kW), automatic tool changers (ATC), CCD cameras for alignment, t-slot table layouts, and safety enclosures. Confirmation of design feasibility should precede purchase agreements.

Do suppliers offer pre-shipment inspection rights?

Most suppliers allow third-party inspections before dispatch. Buyers are advised to engage independent agencies to assess build quality, axis repeatability (±0.01mm tolerance expected), noise levels, and controller interface functionality. Inspection clauses should be formalized in contracts.

What are the common shipping terms and logistics considerations?

FOB terms are standard, with primary loading ports in Qingdao, Shanghai, and Ningbo. Sea freight is recommended for full-container loads due to equipment weight (ranging 2–8 tons). Air freight is viable only for compact benchtop models and incurs significantly higher costs. Ensure proper crating and moisture protection for ocean transport.