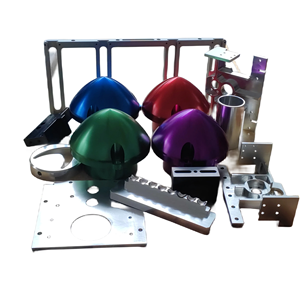

Cnc Precision Machined Components

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About cnc precision machined components

Where to Source CNC Precision Machined Components?

China remains the global hub for high-precision CNC machining, with concentrated supplier clusters in Shenzhen, Dongguan, and Qingdao offering specialized capabilities in tight-tolerance metal and plastic components. Shenzhen and Dongguan in Guangdong Province host over 70% of China’s precision hardware suppliers, supported by mature ecosystems integrating tooling, materials sourcing, and rapid prototyping services. These regions benefit from proximity to Tier-1 electronics and automotive manufacturers, enabling just-in-time delivery models and agile customization.

Qingdao-based facilities leverage integrated supply chains for raw material procurement, reducing lead times by 15–25% compared to non-clustered manufacturers. The region specializes in high-complexity, low-volume production suited for medical, aerospace, and industrial automation sectors. Vertically integrated workshops—equipped with multi-axis CNC milling, turning, and EDM processing—support end-to-end manufacturing under ISO-controlled environments. Buyers gain access to scalable production with typical lead times of 10–20 days for prototypes and 25–35 days for bulk orders, alongside 20–35% cost advantages over Western counterparts.

How to Evaluate CNC Precision Machined Components Suppliers?

Procurement decisions should be guided by structured verification protocols focusing on technical capability, quality assurance, and transaction reliability.

Technical & Production Capacity

Confirm availability of advanced machining infrastructure:

- Minimum 3-axis to 5-axis CNC centers for complex geometries

- In-house EDM (Electrical Discharge Machining) and grinding capabilities for micron-level tolerances (±0.005mm)

- Material expertise across stainless steel (SUS303, SUS316), aluminum alloys (6061, 7075), brass, titanium, and engineering plastics (PEEK, Delrin)

- Demonstrated capacity for secondary operations: anodizing, plating, passivation, laser engraving, and custom packaging

Cross-reference machine inventory with order volume history. Suppliers listing 100+ active machining service SKUs typically maintain larger production floors and dedicated QC teams. Prioritize those with documented R&D or engineering support for design-for-manufacturability (DFM) feedback.

Quality Management Systems

ISO 9001 certification is a baseline requirement for process standardization. For regulated industries (medical, defense, aerospace), verify adherence to AS9100, IATF 16949, or FDA-compliant documentation practices. Request inspection reports including CMM (Coordinate Measuring Machine) data, first-article inspection (FAI), and batch traceability records. On-time delivery rates exceeding 95% correlate strongly with robust internal QA workflows.

Customization & Transaction Reliability

Assess customization depth beyond basic material and finish options. Leading suppliers offer full DFM analysis, tolerance stack-up validation, and prototype iteration within 7–10 days. Minimum Order Quantities (MOQs) vary: some suppliers accept single-piece orders, while others require dozens or hundreds based on setup complexity. Average pricing ranges from $0.50 to $7.00 per unit depending on geometry, material, and finishing requirements.

Evaluate responsiveness (target ≤4 hours) and reorder rates as proxies for customer satisfaction. Reorder rates above 30% indicate strong service consistency. Confirm secure payment terms and dispute resolution mechanisms where applicable.

What Are the Top CNC Precision Machined Components Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Shenzhen Xie Lifeng Technology Co., Ltd. | Shenzhen, CN | Machining Services (1,118) | 98% | ≤4h | 32% | US $930,000+ | Color, material, size, logo, packaging, label, graphic |

| Greasin Precision Technology (Shenzhen) Co., Ltd. | Shenzhen, CN | Machining Services (145) | 100% | ≤3h | <15% | US $10+ | Not specified |

| 24K Investment (Qingdao) Co., Ltd. | Qingdao, CN | Machining Services (166) | 94% | ≤2h | 21% | US $9,000+ | Not specified |

| SkyReach Intelligent MFG Limited | Not specified | Not specified | 84% | ≤4h | 16% | US $20,000+ | Color, material, size, logo, packaging, label, graphic |

| Dongguan Jinchui Precision Hardware Co., Ltd. | Dongguan, CN | Sheet Metal Fabrication (358), Machining Services (51) | 100% | ≤6h | 33% | US $6,000+ | Not specified |

Performance Analysis

Shenzhen Xie Lifeng stands out with the highest online revenue and product breadth, indicating established market presence and diversified client demand. Its 32% reorder rate reflects consistent performance across large-scale contracts. Greasin Precision and Dongguan Jinchui achieve perfect 100% on-time delivery, signaling strong operational control despite lower revenue volumes. Dongguan Jinchui also records the highest reorder rate (33%), suggesting strong customer retention likely driven by reliable quality and communication.

24K Investment (Qingdao) offers fast response times (≤2h) and a balanced mix of machining and fabrication services, suitable for hybrid projects. SkyReach, while advertising broad customization, shows the lowest on-time delivery rate (84%) and moderate reorder frequency, indicating potential fulfillment risks. Buyers prioritizing speed and compliance should favor suppliers with verified delivery records above 95% and clear documentation trails.

FAQs

How to verify CNC machined component supplier credibility?

Request copies of ISO 9001 or equivalent certifications and validate through issuing bodies. Demand sample inspection reports with dimensional data. Conduct virtual factory audits to assess machinery conditions, workflow organization, and QC checkpoints. Analyze historical transaction metrics such as on-time delivery and response speed.

What is the typical MOQ and pricing for CNC machined parts?

MOQs range from 1 piece to 1 dozen depending on part complexity and supplier policy. Unit prices typically start at $0.50 for simple turned components and can exceed $7.00 for multi-feature, tight-tolerance parts requiring secondary processes. High-volume orders (>1,000 units) often qualify for tiered pricing and reduced per-unit costs.

Can suppliers handle full turnkey production?

Yes, many suppliers offer end-to-end services including raw material sourcing, CNC machining, surface treatment, assembly, and kitting. Confirm in advance whether packaging, labeling, and export documentation are included. Suppliers with >100 machining listings generally have the infrastructure for turnkey execution.

Do CNC machining suppliers provide free samples?

Sample policies vary. Some suppliers waive fees for qualified buyers committing to future volume orders. Others charge partial or full production cost for initial samples, which may be credited toward subsequent purchases. Expect 7–14 days for sample production and additional time for international shipping.

How to manage customization requests effectively?

Submit detailed technical drawings (STEP, IGES, DWG) with geometric dimensioning and tolerancing (GD&T). Specify material grade, surface finish, heat treatment, and inspection requirements. Reputable suppliers respond with DFM feedback within 48 hours and deliver functional prototypes within 10–15 days.