Custom Automated Solutions

About custom automated solutions

Where to Find Custom Automated Solutions Suppliers?

China leads global supply of custom automated solutions, with specialized industrial hubs in Shenzhen, Dongguan, and Zhengzhou offering advanced engineering ecosystems. Shenzhen and Dongguan form the core of Guangdong’s automation corridor, hosting over 70% of China’s intelligent equipment manufacturers. These clusters benefit from proximity to semiconductor, electronics, and software development centers, enabling rapid prototyping and integration of AI-driven control systems. Zhengzhou has emerged as a key node for large-scale industrial automation, particularly in automotive and heavy transport assembly, supported by regional government incentives for smart manufacturing.

The concentration of technical talent and component suppliers within these zones allows for vertically integrated production, reducing development lead times by 25–40% compared to decentralized markets. Suppliers leverage co-located CNC machining workshops, robotics labs, and software R&D centers to deliver turnkey systems. Buyers gain access to flexible manufacturing networks capable of fulfilling low-volume bespoke projects or scaling to multi-line deployments. Key advantages include MOQs starting at one unit, average lead times of 45–60 days for complex systems, and cost efficiencies driven by localized sourcing of servo motors, PLCs, and vision sensors.

How to Choose Custom Automated Solutions Suppliers?

Effective supplier selection requires rigorous evaluation across three critical dimensions:

Technical Capability Verification

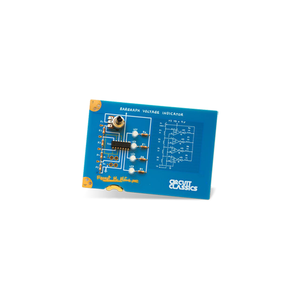

Confirm expertise in relevant automation domains—such as robotic assembly, API integration, or ERP workflows—through product-specific documentation. For hardware-based systems, verify use of industrial-grade components (e.g., Siemens PLCs, Allen-Bradley controllers) and compliance with IEC 61131-3 programming standards. Software-centric providers should demonstrate adherence to secure coding practices and compatibility with major enterprise platforms (SAP, Salesforce, Shopify). ISO 9001 certification is recommended for process consistency, while CE marking indicates conformity with European safety directives.

Production and Development Infrastructure

Assess operational scale and innovation capacity using the following benchmarks:

- Minimum factory area of 3,000m² for physical automation systems

- Dedicated R&D teams with documented project portfolios

- In-house design, programming, and testing capabilities

Cross-reference response times (target ≤8 hours) and on-time delivery rates (preferably ≥97%) as indicators of operational reliability.

Transaction Security and Support Protocols

Utilize secure payment mechanisms such as escrow services that release funds upon successful installation and validation. Prioritize suppliers offering detailed project milestones, remote monitoring during commissioning, and post-deployment technical support. Request system documentation including schematics, user manuals, and API specifications before finalizing contracts. On-site audits or virtual factory tours are strongly advised for high-value installations exceeding $50,000.

What Are the Best Custom Automated Solutions Suppliers?

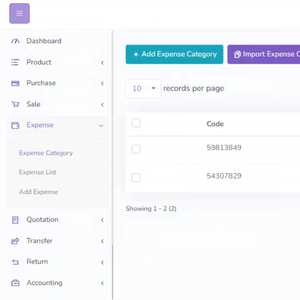

| Company Name | Location | Main Products | Price Range (USD) | MOQ | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Douples Technology Co., Ltd. | Shenzhen, CN | Custom CRM, Mobile App, B2C Website Design | $500 – $30,000+ | 1 unit | 100.0% | ≤8h | Not disclosed | Not disclosed |

| Shenzhen Tianluo Automation Equipment Co., Ltd. | Shenzhen, CN | Industrial Assembly Lines, Packing & Testing Systems | $20,000 – $50,000 | 1 set | 100.0% | ≤5h | US $2,000+ | 100% |

| Dongguan Yicheng Automation Equipment Co., Ltd. | Dongguan, CN | Precision Assembly Machines, Automotive Production Lines | $30,000 – $100,000 | 1 set | 100.0% | ≤7h | Not disclosed | Not disclosed |

| KAEM SOFTWARES PRIVATE LIMITED | India | Digital Process Automation, ERP & HR Software | $95 – $595 | 1–2 units | Not disclosed | ≤2h | US $8,000+ | Not disclosed |

| Zhengzhou Duoyuan Intelligent Equipment Co., Ltd. | Zhengzhou, CN | Bus & Truck Assembly Lines, Welding Workshops | $155,000 – $200,000 | 1 set | 100.0% | ≤8h | Not disclosed | Not disclosed |

Performance Analysis

Shenzhen Tianluo stands out with a 100% reorder rate and sub-5-hour response time, indicating strong client retention and service agility. Dongguan Yicheng targets high-precision manufacturing sectors with solutions priced up to $100,000, reflecting advanced engineering capability. KAEM SOFTWARES offers the lowest entry point for digital automation services, suitable for SMEs seeking scalable software integration. Zhengzhou Duoyuan specializes in ultra-high-capacity vehicle production lines, with transaction values exceeding $195,000 per order, demonstrating capacity for large infrastructure projects. All Chinese suppliers report 100% on-time delivery, a critical metric for synchronized factory planning.

FAQs

How to verify custom automated solutions supplier reliability?

Validate technical claims through project references, system demos, or code repositories. Request proof of compliance with industry standards (e.g., CE, ISO 9001). Analyze customer feedback focusing on post-installation support, debugging responsiveness, and system uptime performance.

What is the typical lead time for customized automation systems?

Software-based solutions typically require 15–30 days. Mechanical systems such as assembly or packing lines take 45–75 days depending on complexity. Integration projects involving legacy equipment may extend to 90 days. Prototypes are usually available within 3–4 weeks for review.

Can suppliers handle global shipping and installation?

Yes, experienced suppliers manage international logistics via sea freight for heavy machinery and air shipment for control units. Many offer engineer dispatch services for on-site commissioning, though associated travel costs are typically borne by the buyer. FOB and CIF terms are commonly available.

Do suppliers provide free samples or pilot systems?

Full-system trials are rare due to customization depth, but modular demonstrations or sandbox environments (for software) are often provided at no cost. For hardware, partial subsystems may be offered for validation at reduced fees, especially for orders above $30,000.

How to initiate a customization request effectively?

Submit detailed requirements including process flowcharts, throughput targets, interface protocols (e.g., REST APIs, OPC UA), power specifications, and environmental conditions. Suppliers with robust engineering teams typically return conceptual designs within 72 hours and formal quotations with timelines within one week.