Namkeen Factory Machine

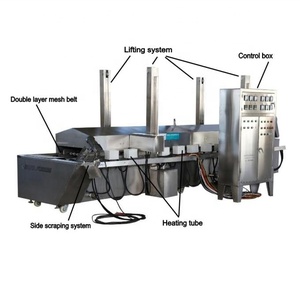

About namkeen factory machine

Where to Find Namkeen Factory Machine Suppliers?

China is a leading manufacturing hub for automated snack processing equipment, including specialized machinery for namkeen production. Key industrial clusters are concentrated in Shandong and Henan provinces, where vertically integrated supply chains support cost-efficient production of continuous fryers, automatic snack forming systems, and full-line automation solutions. Shandong’s machinery sector benefits from proximity to major port infrastructure and stainless steel processing hubs, enabling faster export cycles and reduced material costs. Henan’s food processing equipment ecosystem leverages regional expertise in extrusion, frying, and packaging technologies, with over 40% of suppliers offering turnkey production line integration.

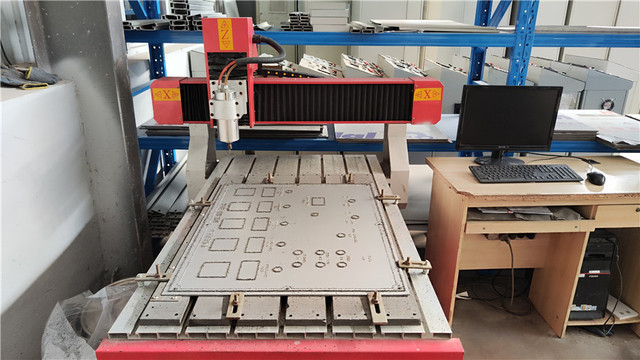

These regions host manufacturers capable of delivering standardized and customized equipment across a wide price spectrum—from compact semi-automatic units at $2,500 to fully integrated lines exceeding $50,000. The clustering effect enables access to precision CNC machining, food-grade material sourcing, and rapid prototyping, reducing lead times for standard orders to 20–35 days. Buyers benefit from localized technical talent pools, high supplier density, and scalable production capacity, particularly for CE-certified or gas-electric hybrid frying systems tailored to Indian, African, and Southeast Asian snack formats like nimki, sev, and onion rings.

How to Choose Namkeen Factory Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Prioritize suppliers offering CE certification for electrical and mechanical safety compliance, especially for exports to regulated markets. Verify use of food-grade stainless steel (e.g., SS304) in contact surfaces and confirm adherence to thermal efficiency standards for oil retention and energy consumption. Request documentation on motor specifications, temperature control ranges (typically 50–200°C), and PLC-based automation features for process consistency.

Production Capability Assessment

Evaluate the following indicators of manufacturing maturity:

- Minimum facility size of 3,000m² for sustained production output

- In-house engineering teams supporting customization (e.g., voltage, belt width, oil tank capacity)

- Proven experience with continuous frying systems and integration of pre-processing units (extruders, cutters, conveyors)

- On-time delivery performance exceeding 96%, as verified through transaction records

Cross-reference product listings with customization tags—such as color, logo, packaging, and capacity modifications—to assess flexibility for brand-specific configurations.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services to align financial release with equipment verification. Analyze reorder rates as a proxy for customer satisfaction; rates above 25% suggest reliable after-sales support and machine durability. Confirm response times under 2 hours to ensure post-purchase service responsiveness. Pre-shipment inspections and sample testing are recommended to validate build quality and frying efficiency before bulk procurement.

What Are the Best Namkeen Factory Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Zhucheng Tianshun Machinery Co., Ltd. | Shandong, CN | $30,000+ | 100% | ≤1h | <15% | Yes | $2,500–13,500 |

| Henan Gelgoog Machinery Co., Ltd. | Henan, CN | $600+ | 100% | ≤1h | <15% | Yes | $3,400–15,000 |

| Jinan Sunward Machinery Co., Ltd. | Shandong, CN | $880,000+ | 96% | ≤3h | 45% | Yes | $5,000–40,000 |

| Shandong Xinlongjia Automation Equipment Co., Ltd. | Shandong, CN | $80,000+ | 100% | ≤2h | 25% | Yes | $3,250–6,950 |

| Henan Ultron Intellegent Technology Co., Ltd. | Henan, CN | $140,000+ | 100% | ≤1h | <15% | Yes | $3,600–70,000 |

Performance Analysis

Suppliers like Zhucheng Tianshun and Henan Ultron demonstrate strong export readiness with 100% on-time delivery and sub-hour response times, making them suitable for time-sensitive procurement. Jinan Sunward stands out with a 45% reorder rate—indicating high customer retention—despite a slightly longer average response window. Henan-based firms dominate responsiveness, with three suppliers achieving ≤1-hour reply times. For budget-conscious buyers, Shandong Xinlongjia offers competitively priced continuous fryers ($3,250–6,950) with solid performance metrics. High-end system integrators like Henan Ultron cater to vacuum-frying applications with premium solutions up to $70,000, targeting specialty snack producers. All listed suppliers offer customization for material, size, logo, and packaging, confirming adaptability to regional market needs.

FAQs

What certifications should namkeen machine suppliers have?

CE certification is essential for compliance in European and many emerging markets. ISO 9001 indicates structured quality management. While not always present in listings, verify that electrical components meet IEC standards and that heating systems comply with local gas or power regulations.

What is the typical minimum order quantity (MOQ)?

Most suppliers list an MOQ of 1 set or unit, facilitating low-volume trial purchases. This allows buyers to evaluate machine performance before scaling to full-line deployment.

How long does it take to receive a namkeen production machine?

Lead times for standard models typically range from 20 to 35 days after order confirmation. Customized systems may require an additional 10–15 days depending on complexity. Air freight reduces shipping time to 5–7 days but increases logistics costs significantly.

Can suppliers integrate multiple production stages?

Yes, several suppliers offer end-to-end solutions combining dough feeding, shaping, frying, seasoning, and packaging. These integrated lines improve throughput and reduce labor input, particularly for high-volume operations producing kurkure, chips, or fried legumes.

Do manufacturers provide installation and training support?

While not universally offered, many suppliers include remote guidance via video or manuals. Some provide on-site technician deployment at additional cost. Confirm service terms during negotiation, especially for automated control systems requiring PLC programming knowledge.