Prototype Assembly

CN

CN

1/20

1/20

1/11

1/11

1/48

1/48

1/61

1/61

1/48

1/48

1/14

1/14

CN

CN

1/24

1/24

CN

CN

1/35

1/35

1/21

1/21

About prototype assembly

Where to Find Prototype Assembly Suppliers?

China remains a dominant hub for prototype assembly services, with key manufacturing clusters in Fujian and Guangdong provinces offering specialized capabilities in rapid prototyping, low-volume production, and electronics integration. Xiamen and Shenzhen serve as primary innovation centers, hosting vertically integrated facilities that combine CNC machining, 3D printing, and PCB assembly under one roof. These regions benefit from mature supplier ecosystems, enabling fast turnaround times and tight coordination between design, fabrication, and testing phases.

The industrial infrastructure supports both mechanical and electronic prototyping, with many suppliers operating ISO-certified environments and maintaining in-house tooling, SMT lines, and metrology labs. This integration reduces dependency on external vendors, cutting lead times by up to 40% compared to fragmented supply chains. Buyers gain access to agile manufacturers capable of handling orders from single-piece prototypes to small-batch pre-production runs, typically within 7–15 days depending on complexity.

How to Choose Prototype Assembly Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capabilities & Certifications

Prioritize suppliers with ISO 9001 certification as a baseline for quality management. For electronic assemblies, verify compliance with RoHS and UL standards, particularly when targeting EU or North American markets. Confirm the use of lead-free processes and controlled soldering profiles. In high-precision applications—such as aerospace or medical devices—demand evidence of CMM inspection reports, first-article testing, and traceability protocols.

Production Flexibility and Scalability

Assess capacity for both customization and volume ramp-up:

- Minimum Order Quantity (MOQ) ranging from 1 piece to 200 sets indicates flexibility for R&D-stage projects

- In-house CNC, 3D printing (SLM/DMLS), and SMT lines enable faster iteration cycles

- Component sourcing support, including BOM validation and obsolescence management, is critical for full turnkey PCBA services

Cross-reference response times (target ≤4 hours) and on-time delivery rates (ideal ≥98%) with order history to assess reliability.

Transaction Security and Communication Efficiency

Favor suppliers with documented reorder rates above 60%, indicating customer retention and service consistency. Short response times (≤2 hours) correlate with proactive project management. Utilize secure payment mechanisms where available, and request sample builds before committing to larger volumes. Video audits of production floors can validate claims about automation levels and quality control checkpoints.

What Are the Best Prototype Assembly Suppliers?

| Company Name | Main Services | Min. Order | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Verification |

|---|---|---|---|---|---|---|---|---|

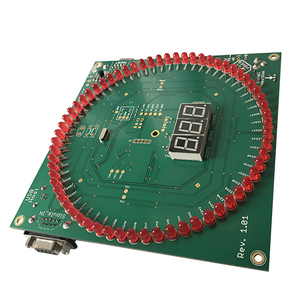

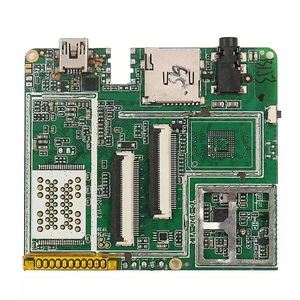

| Xiamen Sanzhu Sporting Goods Co., Ltd. | CNC Machining, 3D Printing, Metal SLM/DMLS | 1 piece | $0.90–2.00 | 100% | ≤4h | 100% | $2,000+ | - |

| Shenzhen Kaiyuanda Electronic Technology Co., Ltd. | PCB Assembly, SKD/ODM Electronics | 200–1,000 sets | $2.50–3.50 | 100% | ≤6h | <15% | $10,000+ | - |

| Toptek Pcb Co., Limited | Prototype PCB, FR4, Heavy Copper, IoT Boards | 1 piece | $0.80–2.01 | 100% | ≤2h | 66% | $1,000+ | Multispecialty Supplier |

| Shenzhen Zhuopin High-Tech Electronics Co., Ltd. | Long-Size PCBA, Reverse Engineering, Custom Boards | 10 pieces | $0.01+ | 100% | ≤1h | <15% | $10,000+ | Multispecialty Supplier |

| Sunsoar Tech Co., Limited | OEM SMT, Multilayer PCB, Solar Inverters | 2–20 pieces | $0.80–5.80 | 100% | ≤3h | 100% | $10,000+ | - |

Performance Analysis

Suppliers like Xiamen Sanzhu and Sunsoar Tech demonstrate strong customer loyalty with 100% reorder rates, suggesting consistent output quality and responsive communication. Toptek Pcb and Shenzhen Zhuopin stand out for ultra-fast response times (≤2h and ≤1h respectively), which is crucial during iterative development stages. While several companies offer $0.01 pricing tiers, these often apply to basic layers or promotional offers—actual per-unit costs depend on layer count, materials, and component complexity. Shenzhen-based firms dominate in electronics-focused prototyping, especially for IoT and power systems, whereas Fujian-based providers excel in hybrid mechanical-electronic builds using multi-process workflows.

FAQs

How to verify prototype assembly supplier reliability?

Confirm certifications (ISO 9001, RoHS, UL) through official databases or third-party verification platforms. Request process documentation such as FAI reports, solder paste inspection (SPI) data, and AOI results. Analyze transaction history for on-time delivery consistency and review feedback related to revision handling and defect resolution.

What is the typical lead time for prototype assemblies?

Standard PCB or CNC prototypes take 5–10 days, while complex metal 3D printed parts (SLM/DMLS) may require 10–18 days due to post-processing requirements. Expedited services are available at a premium, reducing timelines by 3–5 days. Add 3–7 days for international air shipping.

Do suppliers support component sourcing for PCBA?

Yes, leading providers offer full BOM fulfillment, including active component procurement, counterfeit mitigation, and alternative part recommendations. Turnkey services reduce client burden but require clear specifications and approval workflows for substitutions.

Can I request a single-piece prototype?

Most suppliers accommodate 1-piece MOQs, especially for initial design validation. However, pricing per unit decreases significantly at 5–10 piece batches. Ensure gerber files, pick-and-place data, and assembly drawings are complete to avoid delays.

Are custom materials and finishes supported?

Suppliers commonly work with FR4, aluminum, and flexible substrates for PCBs, and stainless steel, titanium, and engineering plastics for mechanical parts. Surface finishes include ENIG, HASL, anodizing, and powder coating—confirm compatibility with functional or environmental requirements upfront.