Prototype Machine Services

CN

CN

Top sponsor listing

Top sponsor listing

CN

CN

1/13

1/13

1/3

1/3

1/3

1/3

1/3

1/3

1/26

1/26

0

0

1/3

1/3

1/23

1/23

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/26

1/26

0

0

0

0

1/3

1/3

0

0

1/3

1/3

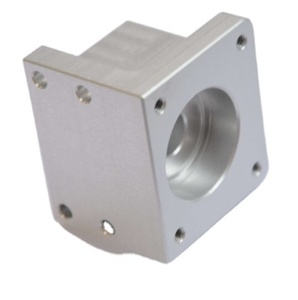

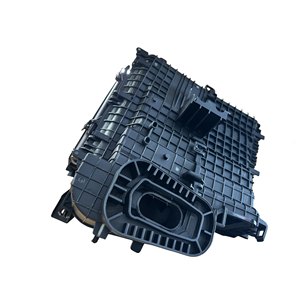

About prototype machine services

Where to Find Prototype Machine Services Suppliers?

China remains a central hub for prototype machine services, with key manufacturing clusters in Shenzhen, Dongguan, and Yuyao driving innovation and efficiency in rapid prototyping. These regions host vertically integrated facilities specializing in CNC machining, 3D printing (SLA, SLS, MJF), vacuum casting, and sheet metal fabrication. Shenzhen and Dongguan benefit from proximity to high-tech R&D centers and advanced material supply chains, enabling fast iteration cycles and tight tolerances down to ±0.05mm.

The industrial ecosystem supports both low-volume prototyping and scalable pre-production runs. Integrated workshops combine design validation, tooling, and functional testing under one roof, reducing time-to-market by up to 40% compared to fragmented outsourcing models. Buyers gain access to agile suppliers capable of fulfilling orders within 5–15 days for standard prototypes, with localized logistics cutting shipping delays. Cost efficiencies stem from competitive labor rates and bulk material sourcing, offering 20–35% savings over Western-based providers for equivalent precision work.

How to Choose Prototype Machine Services Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capabilities Verification

Confirm expertise in required processes: CNC milling (3-axis, 5-axis), injection molding, SLA/SLS 3D printing, or urethane casting. Review equipment inventories—suppliers with multi-technology platforms offer greater flexibility for hybrid projects. Prioritize those providing DFM (Design for Manufacturing) feedback and material compatibility analysis prior to production.

Quality Assurance Protocols

While formal certifications (e.g., ISO 9001) are not universally listed, performance indicators such as on-time delivery rates (>90%) and response times (<6 hours) serve as proxies for operational discipline. Suppliers reporting reorder rates below 20% suggest lower customer churn and higher satisfaction. Inquire about in-process inspection procedures, first-article reporting, and post-processing quality checks for surface finish and dimensional accuracy.

Customization & Communication Efficiency

Evaluate customization depth: color, material grade (ABS, PC, nylon, stainless steel), labeling, packaging, and geometric complexity. Fast response times—some suppliers achieve ≤1 hour—are critical for iterative design corrections. Ensure digital collaboration tools (CAD file sharing, progress updates via video) are available to support remote oversight.

Transaction Risk Mitigation

Assess online revenue history as an indicator of market presence and order volume stability. Use secure payment mechanisms where possible, especially for initial engagements. Request sample prototypes before full-scale production to validate quality consistency, material properties, and assembly fit.

What Are the Best Prototype Machine Services Suppliers?

| Company Name | Main Products/Services | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Anqing Wayne Hand Model Technology Co., Ltd. | Machining, Sheet Metal, Casting, 3D Printing | 91% | ≤1h | 45% | $220,000+ | Color, material, size, logo, packaging, graphic | 1 piece | $3.89–$10.70 |

| Dongguan Yyi Technology Co., Ltd. | Machining Services, SLA/SLS/MJF, Resin/Nylon | 100% | ≤2h | 53% | $30,000+ | Color, material, size, logo, packaging, graphic | 1 piece | $1.29–$6.90 |

| Yuyao City Yunpeng Plastic Mould Co., Ltd. | 3D Rapid Prototyping, CNC Machining, SLA/SLS | 100% | ≤3h | <15% | Not specified | Color, material, size, logo, packaging, graphic | 1 set | $10–$5,000 |

| Shenzhen Xinbanghui Hardware Products Co., Ltd. | Machining Services | 100% | ≤6h | <15% | $10,000+ | Color, material, size, logo, packaging, graphic | Not specified | Not specified |

| Yuyao Taike Mold Factory | Machining, Moulds, Vacuum Casting, CNC | 82% | ≤4h | 42% | $20,000+ | Not explicitly stated | 1 acre* | $2.40–$4.60 |

*Note: “acre” likely reflects data entry error; context suggests “piece” or “set” is intended.

Performance Analysis

Anqing Wayne and Dongguan Yyi demonstrate strong technical agility with sub-$7 pricing per unit and delivery reliability above 90%. Dongguan Yyi stands out with a 100% on-time rate and high reorder frequency (53%), indicating consistent output quality. Yuyao City Yunpeng offers broad process coverage and zero late deliveries, supported by rapid 3-hour average responses. Shenzhen Xinbanghui maintains low customer turnover (<15% reorder rate), suggesting niche specialization or limited scalability. Anqing Wayne leads in revenue transparency ($220K+), reflecting sustained commercial activity. Suppliers like Yuyao Taike, despite lower punctuality (82%), provide cost-effective solutions for non-critical timelines.

FAQs

How to verify prototype machine service supplier reliability?

Assess responsiveness, historical delivery performance, and customization transparency. Request evidence of past project execution, including CAD-to-part workflows and finish treatment capabilities. Verify material traceability and compliance with RoHS or REACH if applicable for end-use applications.

What is the typical lead time for prototype production?

Standard prototypes take 5–12 days depending on complexity and technology used. CNC-machined parts typically deliver in 7–10 days; 3D-printed models can be completed in 3–5 days. Add 3–5 days for surface finishing or assembly. Expedited services may reduce turnaround to 3–5 days at premium cost.

Do suppliers support small MOQs and custom materials?

Yes, most suppliers accept minimum orders of 1 piece or set. Material options include ABS, PC, POM, nylon, aluminum, and stainless steel. Custom resins, high-temp polymers, or biocompatible grades may require surcharges or extended sourcing timelines.

Can I request design modifications during production?

Iterative adjustments are feasible, particularly with digital fabrication methods. However, changes after tooling or batch initiation may incur rework fees. Clear communication through annotated drawings or 3D files minimizes misinterpretation.

Are samples available before mass production?

Prototypes function as functional samples. Most suppliers include one-off builds in standard quoting. Additional iterations for refinement are billable but recommended for complex assemblies or mission-critical components.