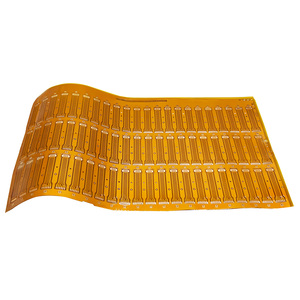

Quick Turn Flex Circuits

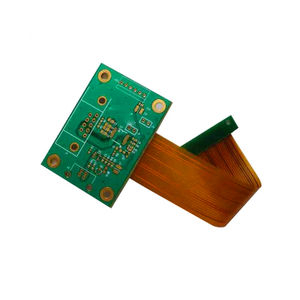

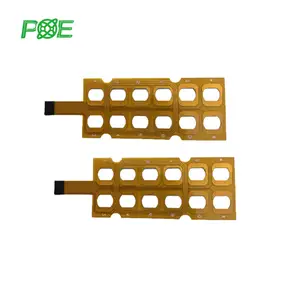

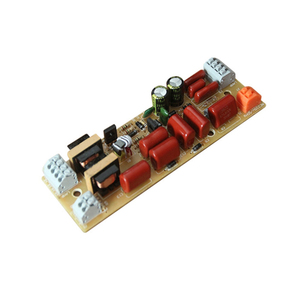

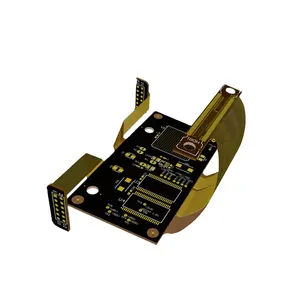

About quick turn flex circuits

Where to Find Quick Turn Flex Circuits Suppliers?

China remains the global hub for quick turn flex circuit manufacturing, with key production clusters concentrated in Shenzhen, Guangzhou, and surrounding Pearl River Delta regions. These industrial zones host vertically integrated facilities specializing in rapid prototyping and low-to-medium volume production of flexible and rigid-flex printed circuit boards (FPCs). The region’s mature electronics supply chain enables streamlined access to polyimide films, adhesiveless laminates, and precision etching equipment—critical materials and processes for high-reliability flex circuits.

Suppliers in this ecosystem leverage localized component sourcing and automated fabrication lines to achieve lead times as fast as 3–7 days for single-layer prototypes and 5–10 days for multilayer configurations. Economies of scale, combined with lean inventory models, allow manufacturers to offer competitive pricing without minimum order quantity (MOQ) constraints on select product lines. Buyers benefit from agile production cycles, enabling rapid design validation and time-to-market acceleration for consumer electronics, medical devices, and IoT applications.

How to Choose Quick Turn Flex Circuits Suppliers?

Selecting a reliable supplier requires due diligence across technical, operational, and transactional dimensions:

Technical Capability Assessment

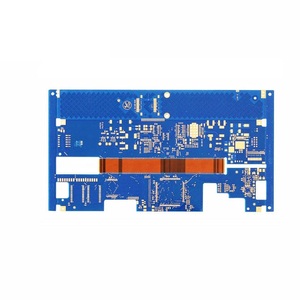

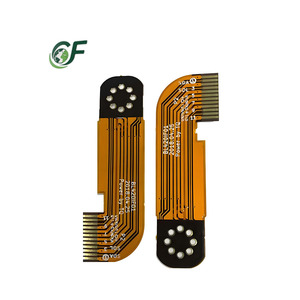

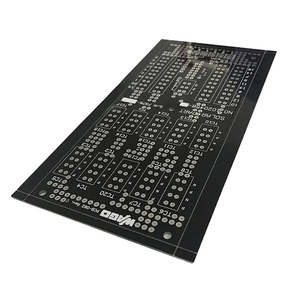

Verify expertise in flex-specific processes such as laser micro-via drilling, controlled-depth routing, and dynamic bend testing. Confirm support for critical specifications including impedance control, coverlay registration accuracy (±0.05mm), and thin copper (<18μm) processing. Multilayer and rigid-flex capabilities should be supported by lamination process validation and thermal stress testing (e.g., 288°C solder float).

Quality Management Systems

Prioritize suppliers with ISO 9001 certification and adherence to IPC-6013 (flexible PCB qualification). RoHS and REACH compliance is essential for market access in Europe and North America. Review available test reports for peel strength, solderability, and insulation resistance. On-time delivery rates exceeding 95% and response times under 4 hours indicate strong operational discipline.

Production Scalability & Customization

Evaluate customization scope: look for support in material selection (e.g., Pyralux, Upilex), surface finishes (ENIG, Immersion Tin), and value-added services like component replication, Gerber file optimization, and PCBA assembly. Suppliers offering one-stop prototyping-to-production workflows reduce coordination overhead. Cross-reference listed product volumes—particularly FPC and Rigid-Flex PCB counts—with reorder rates to assess customer retention and service consistency.

Procurement Safeguards

Utilize secure payment mechanisms where applicable, particularly for initial engagements. Request sample builds to validate dimensional accuracy, layer alignment, and electrical performance before scaling. Confirm packaging standards (ESD-safe, humidity-controlled) for sensitive shipments. For repeat orders, negotiate tiered pricing based on volume milestones.

What Are the Best Quick Turn Flex Circuits Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|

| Toptek Pcb Co., Limited | Data not specified | 100% | ≤2h | 66% | US $1,000+ | $0.90–1.20 | 1 piece |

| Topfast Technology Co.,Ltd. | FPC (310), Rigid-Flex PCB (331) | 97% | ≤4h | 45% | US $610,000+ | $0.50–3.90 | 1–2 pieces |

| Finest PCB Assemble Limited | Customization options noted | 81% | ≤3h | <15% | US $9,000+ | $1.50–5.00 | 1–10 pieces |

| Guangzhou Highleap Electronic Co., Ltd. | FPC (310), Rigid-Flex PCB (331) | 94% | ≤2h | 28% | US $280,000+ | $0.50–5.00 | 1 piece |

| Shenzhen Cengfeng Electronics Co., Ltd. | FPC (22), Multilayer PCB (121) | 100% | ≤4h | Not available | Not available | $0.99–7.79 | 1 piece |

Performance Analysis

Toptek Pcb Co., Limited and Shenzhen Cengfeng Electronics demonstrate perfect on-time delivery records, indicating robust production planning. Topfast Technology stands out with over 300 listings in FPC and rigid-flex categories, coupled with a high reorder rate and substantial online revenue—suggesting strong market acceptance. Guangzhou Highleap offers broad price flexibility ($0.50–5.00) and fast response times, ideal for iterative prototyping. While Finest PCB Assemble has lower reorder metrics, its focus on graphic and color customization may serve niche design-driven applications. Suppliers with higher transaction volumes generally provide more consistent quality assurance and logistics reliability.

FAQs

What is the typical lead time for quick turn flex circuits?

Standard lead times range from 3 to 7 days for single-layer flex circuits and 5 to 10 days for multilayer or rigid-flex designs. Rush services may reduce turnaround to 48–72 hours, depending on complexity and factory load.

Do suppliers support prototype-only orders?

Yes, most suppliers accommodate prototype orders with MOQs as low as 1 piece. Unit pricing is higher at low volumes but decreases significantly at 10+ and 50+ unit tiers.

Are Gerber files and design support included?

Reputable suppliers provide free Gerber file review and DFM (Design for Manufacturability) feedback. Some offer design correction or optimization services, especially for impedance-controlled or high-density layouts.

What materials are commonly used in quick turn flex circuits?

Polyimide (PI) films such as Kapton or Pyralux are standard. Adhesiveless constructions are preferred for improved thermal stability and thinner profiles. Coverlays and stiffeners (polyester or FR4) are available upon request.

Can flex circuits be assembled with components?

Yes, many suppliers offer integrated PCBA services including SMT, wave soldering, and testing. Capabilities vary—confirm availability of fine-pitch placement, BGA assembly, and conformal coating if required.