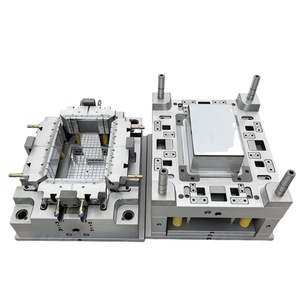

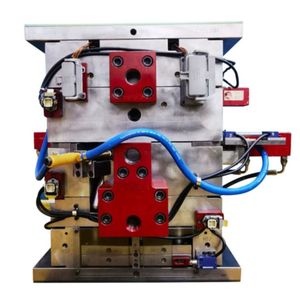

Molded Precision Components

About molded precision components

Where to Find Molded Precision Components Suppliers?

China remains a central hub for the production of molded precision components, with key manufacturing clusters located in Guangdong and Jiangsu provinces. These regions host vertically integrated supply chains that combine advanced injection molding, CNC machining, and stamping capabilities under one ecosystem. Dongguan and Shenzhen in Guangdong province are particularly notable for their specialization in high-tolerance plastic and metal molding, supported by mature tooling infrastructure and proximity to international logistics hubs.

The concentration of technical expertise and component suppliers within 50km radii enables rapid prototyping and scalable production. Facilities in these zones typically operate automated production lines capable of achieving tolerances down to ±0.01mm, with materials ranging from engineering plastics (ABS, PEEK, PC) to hardened steels and aluminum alloys. Buyers benefit from lead times averaging 20–35 days for custom orders, 15–25% lower unit costs compared to Western manufacturers, and strong flexibility in batch sizing—from prototypes to high-volume runs.

How to Choose Molded Precision Components Suppliers?

Selecting reliable suppliers requires a structured evaluation of technical, operational, and transactional factors:

Quality Management Systems

Confirm adherence to ISO 9001 standards as a baseline for process control. For medical, automotive, or aerospace applications, request evidence of sector-specific compliance (e.g., IATF 16949, AS9100). Review documentation on material traceability, in-process inspections, and final product testing protocols.

Production & Engineering Capacity

Assess core capabilities through the following indicators:

- Minimum facility size of 2,000m² to support dedicated molding and machining zones

- In-house mold design and fabrication teams (preferably with >10 engineers)

- Availability of multi-cavity and 2K/overmolding technologies for complex assemblies

- CNC, EDM, and surface grinding integration for tight-tolerance components

Cross-reference supplier claims with on-time delivery performance (target ≥94%) and response time (ideally ≤4 hours).

Customization and Transaction Security

Prioritize suppliers offering full OEM/ODM support, including 2D/3D design validation, material selection guidance, and packaging customization. Utilize secure payment mechanisms such as escrow services, and request physical or digital samples before committing to large orders. Verify reorder rates as an indicator of customer satisfaction—rates above 30% suggest consistent quality and service reliability.

What Are the Best Molded Precision Components Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Main Product Focus |

|---|---|---|---|---|---|---|---|

| Dongguan Tongsheng Metal Technology Co., Ltd. | Dongguan, CN | US $40,000+ | 94% | ≤2h | 31% | Color, material, size, logo, packaging, graphic | Precision injection molding, metal stamping dies |

| Shenzhen Shunheng Precision Mould Co., Ltd. | Shenzhen, CN | US $90,000+ | 100% | ≤4h | <15% | Color, mold design, packaging, drawings, part weight, dimensions | Plastic injection molds, medical & automotive molds |

| Kunshan Feiya Precision Moulding Co., Ltd. | Kunshan, CN | US $60,000+ | 100% | ≤4h | 66% | Limited customization noted | Mold parts, steel inserts, stamping components |

| Dongguan Tuoyu Precision Hardware Co., Ltd. | Dongguan, CN | US $80,000+ | 100% | ≤2h | 45% | Size, material, design, packaging | Stamping dies, punch components, metal pins |

| Shenzhen World Star Industry Limited | Shenzhen, CN | US $8,000+ | 80% | ≤9h | 25% | Design, material, color, packaging | Kitchenware molds, plastic handles, consumer goods |

Performance Analysis

Shenzhen Shunheng and Kunshan Feiya demonstrate exceptional on-time delivery (100%), indicating robust production planning and quality control. Dongguan Tuoyu stands out for responsiveness (≤2h) and a high reorder rate (45%), suggesting strong client engagement. While Shenzhen World Star offers design-focused customization, its lower on-time delivery rate (80%) may pose risks for time-sensitive contracts. Suppliers like Kunshan Feiya, with a 66% reorder rate, reflect high customer retention likely due to consistent output quality. For critical applications, prioritize suppliers with documented engineering input, preferably those providing 3D drawing support and mold flow analysis.

FAQs

How to verify molded precision components supplier reliability?

Validate certifications through issuing bodies and request audit trails covering raw material sourcing, process controls, and inspection records. Analyze historical transaction data, focusing on delivery consistency and dispute resolution outcomes. Conduct virtual factory audits to observe equipment conditions and workflow organization.

What is the typical sampling timeline for molded components?

Prototype samples generally take 7–15 days for plastic injection parts and 10–20 days for metal-stamped or machined components. Complex multi-material or overmolded parts may require up to 25 days. Add 5–10 days for international air shipping.

Can suppliers handle global shipping and customs compliance?

Yes, most established suppliers manage export logistics, including FOB and CIF arrangements. Confirm familiarity with destination-market import regulations, especially for regulated industries. Ensure proper documentation for material composition (e.g., RoHS, REACH) is provided upon request.

Do suppliers offer free samples?

Sample policies vary. Some suppliers waive fees for potential bulk orders (typically MOQ >1,000 units), while others charge partial or full sample costs. Expect pricing between $0.10–$100 per unit depending on complexity and material.

What customization options are commonly available?

Standard customization includes material selection, color matching (Pantone/RAL), dimensional adjustments, logo imprinting, and packaging configuration. Advanced providers support full design-from-scratch projects, mold development, and integration of secondary processes such as ultrasonic welding or insert molding.